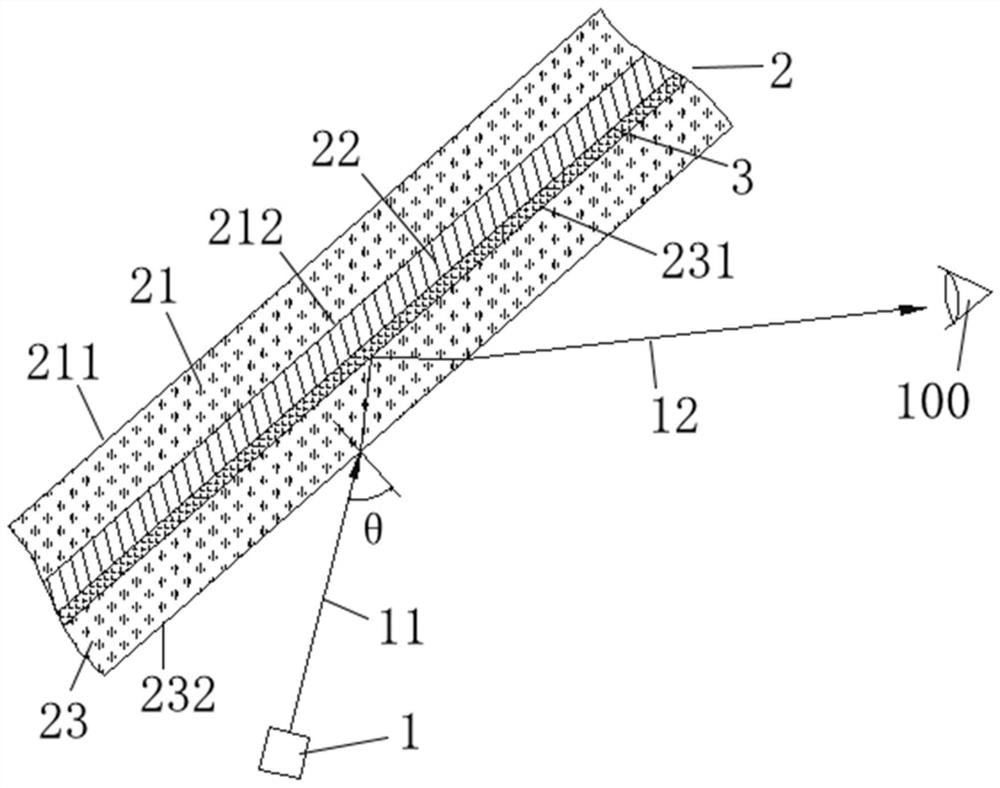

Head-up display system

A head-up display system and control system technology, applied in the field of head-up display, can solve the problems of high visible light transmittance, high P-polarized light reflectance, low visible light reflectance, etc., to achieve high visible light transmittance, P-polarized light reflection High rate, eliminate reddish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1

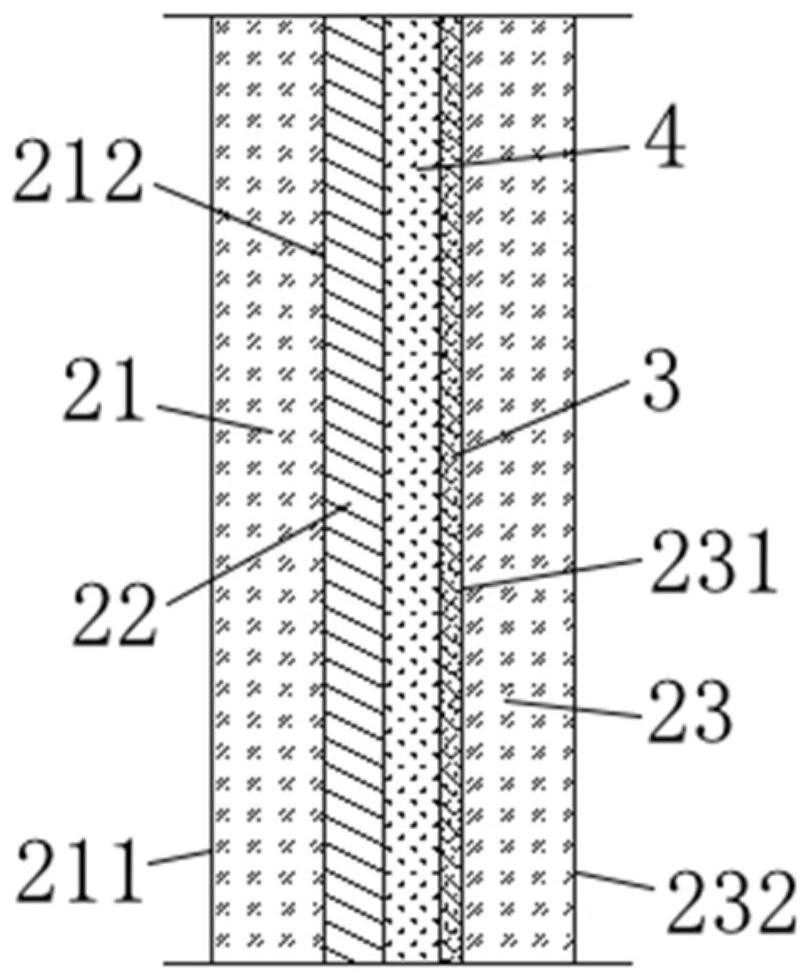

[0064] The present invention prepares the outer glass plate, the inner glass plate and at least one intermediate bonding layer by designing the film system structure of the transparent nano film and adjusting the thickness of the inner glass plate, and obtains Examples 1-5 and Comparative Example 1 according to the automobile glass production process .

Embodiment 1

[0066] Laminated glass: outer glass plate (2.1mm white glass) / PVB (0.76mm) / transparent nano film / inner glass plate (1.0mm white glass)

[0067] Transparent nano film: white glass(1.0mm) / SiO2(15nm) / SiN(41.2nm) / AZO(10nm) / Ag(7.0nm) / NiCr(0.35nm) / AZO(5nm) / Ag(5.0nm) / AZO(10nm) / SiN(40nm);

Embodiment 2

[0069] Laminated glass: outer glass plate (2.1mm white glass) / transparent nano film / PVB (0.76mm) / inner glass plate (0.7mm white glass)

[0070] Transparent nano film: white glass(2.1mm) / ZnSnOx(24.0nm) / TiO2(3.1nm) / AZO(10nm) / AgCuPt(5.0nm) / AZO(10nm) / TiN(2.0nm) / TiO2(8.6nm) / ZnSnOx(48.7nm) / AZO(10nm) / AgCu(5.0nm) / AZO(10nm) / ZnSnOx(56.7nm) / TiO2(17.4nm) / AZO(5nm) / AgCuPt(15.0nm) / AZO(5nm) / TiO2(16.9nm) / ZnSnOx(23.9nm) / SiN(5.0nm);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com