A kind of egg yolk-shell structure manganese potassium ore type manganese dioxide catalyst and its preparation method and application

A technology of manganese dioxide and shell structure, which is applied in the field of egg yolk-shell structure manganese potassium ore-type manganese dioxide catalyst and its preparation, can solve the problems of long synthesis cycle and high device pressure, and achieve low cost, high catalytic activity, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1.58g of ammonium bicarbonate in 25mL of deionized water, add 500mL of cyclohexane, 25mL of n-butanol, and 20g of cetyltrimethylammonium bromide, and continue stirring until the solution is clear.

[0024] After dissolving 1.69g of manganese sulfate in 25mL of water, add it dropwise to the above mixture, and keep stirring for 20min.

[0025] The solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

[0026] Put it into a vacuum oven at 90°C for 8 hours to obtain manganese carbonate powder.

[0027] Dissolve 1 g of the dried manganese carbonate powder in 272 mL of deionized water, add 1.375 g of potassium permanganate, ultrasonicate for 2 min, and stir for 20 min.

[0028] The obtained solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

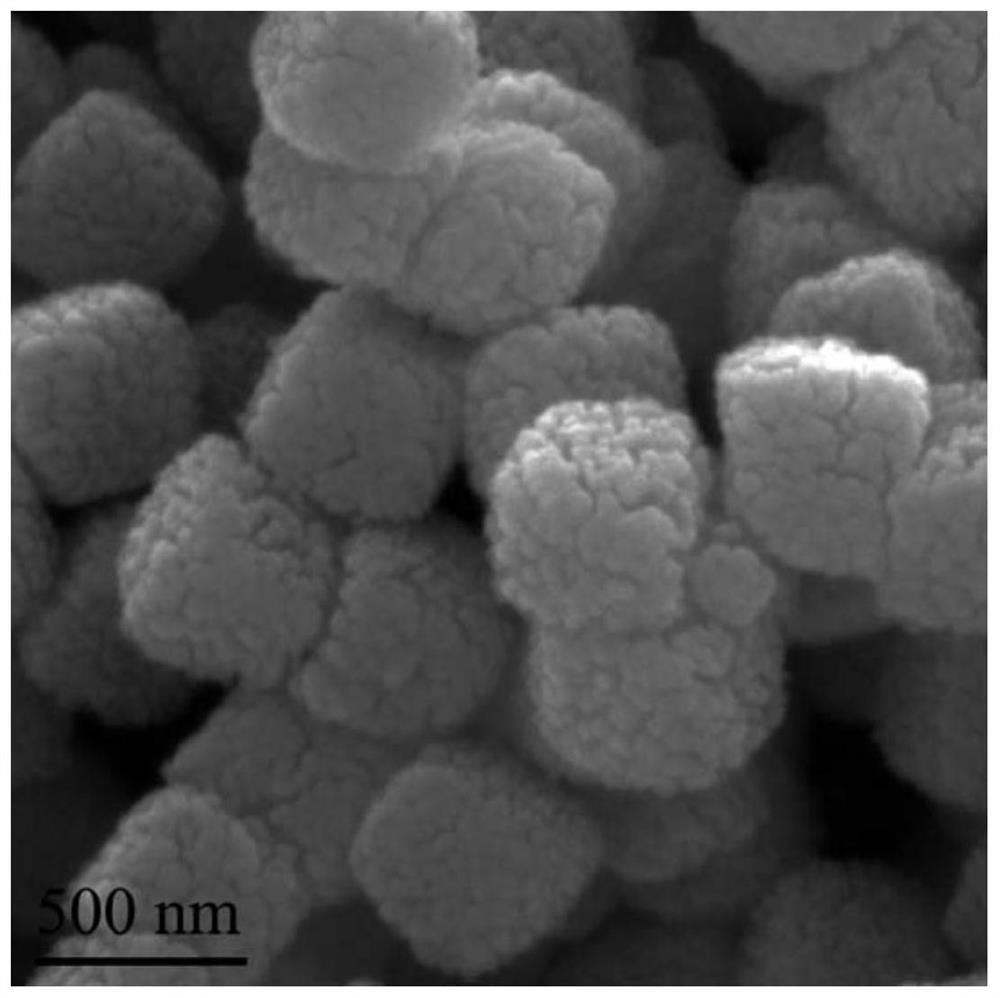

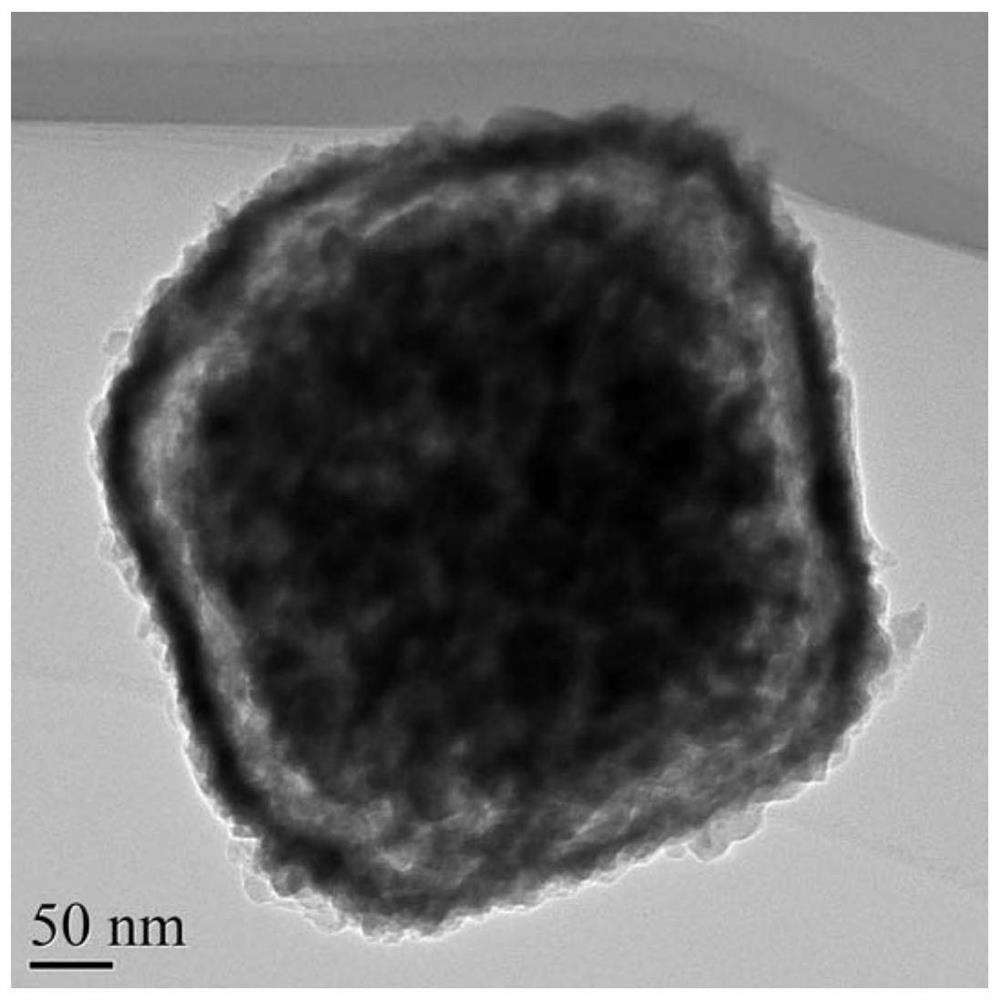

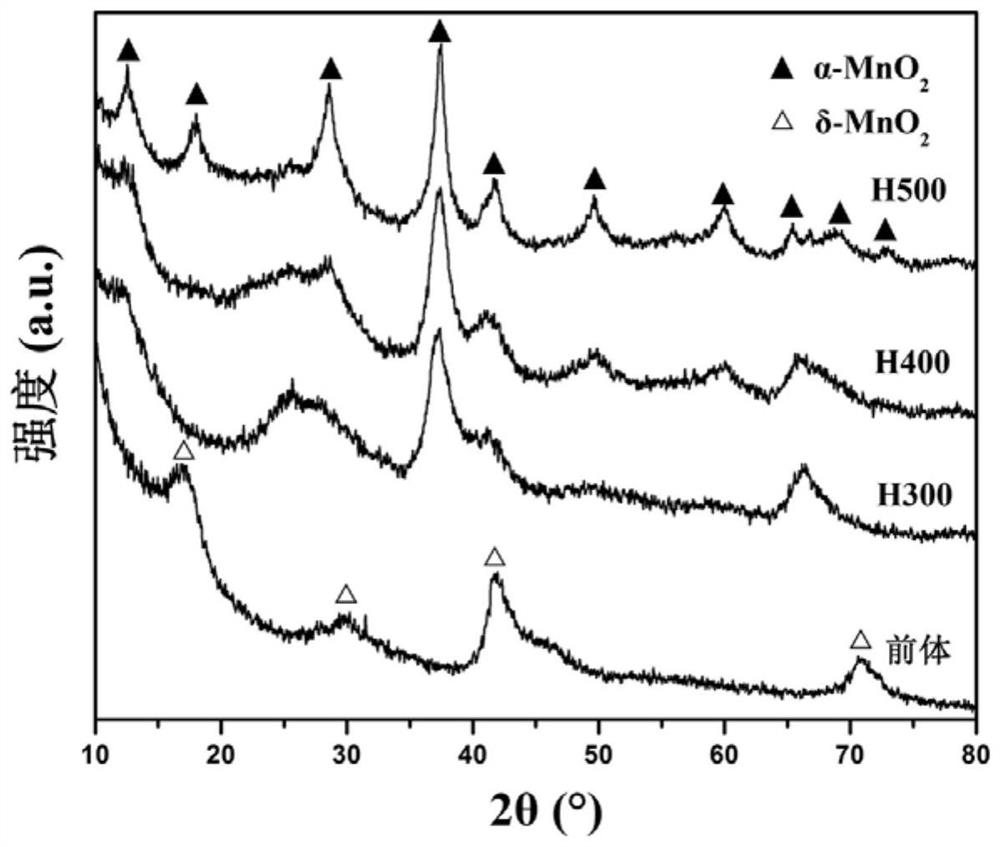

[0029] Put it into an oven at 100°C and dry for 8 hours to obtain a precursor...

Embodiment 2

[0032] Dissolve 1.58g of ammonium bicarbonate in 25mL of deionized water, add 500mL of cyclohexane, 25mL of n-butanol, and 20g of cetyltrimethylammonium bromide, and continue stirring until the solution is clear.

[0033] After dissolving 1.69g of manganese sulfate in 25mL of water, add it dropwise to the above mixture, and keep stirring for 20min.

[0034] The solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

[0035] Put it into a vacuum oven at 90°C for 8 hours to obtain manganese carbonate powder.

[0036] Dissolve 1 g of the dried manganese carbonate powder in 272 mL of deionized water, add 1.375 g of potassium permanganate, ultrasonicate for 2 min, and stir for 20 min.

[0037] The obtained solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

[0038] Put it into an oven at 100°C and dry for 8 hours to obtain a precursor...

Embodiment 3

[0041] Dissolve 1.58g of ammonium bicarbonate in 25mL of deionized water, add 500mL of cyclohexane, 25mL of n-butanol, and 20g of cetyltrimethylammonium bromide, and continue stirring until the solution is clear.

[0042] After dissolving 1.69g of manganese sulfate in 25mL of water, add it dropwise to the above mixture, and keep stirring for 20min.

[0043] The solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

[0044] Put it into a vacuum oven at 90°C for 8 hours to obtain manganese carbonate powder.

[0045] Dissolve 1 g of the dried manganese carbonate powder in 272 mL of deionized water, add 1.375 g of potassium permanganate, ultrasonicate for 2 min, and stir for 20 min.

[0046] The obtained solution was centrifuged at 9000r for 3~5min, and the solid residue was washed with ethanol and water alternately for 3 times.

[0047] Put it into an oven at 100°C and dry for 8 hours to obtain a precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com