Homogenizing preparation technique of zirconium oxide/aluminum oxide composite photo-sensitive paste based on SLA-3D (stereo lithography apparatus-three dimensional) printing

A SLA-3D, zirconia technology, applied in the direction of additive processing, can solve the problems of affecting the final quality of parts, difficulty in sintering and densification, unfavorable precision forming, etc., to achieve the advantages of sintering densification and shape accuracy, and solve the difficulty of powder dispersion. , the effect of maintaining dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

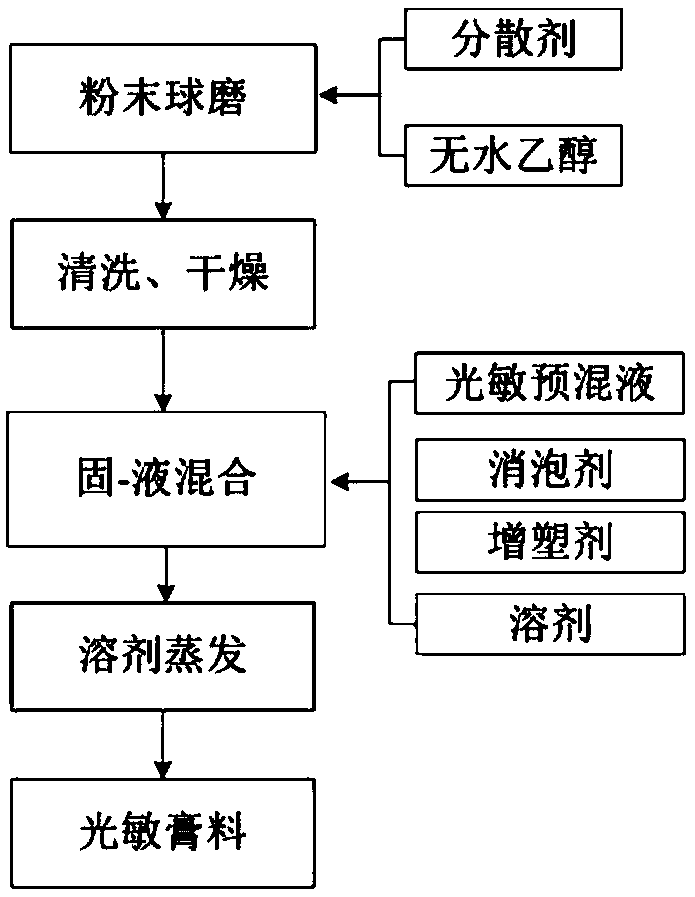

[0047] Such as figure 1 As shown, a zirconia / alumina composite photosensitive paste homogenization preparation technology based on SLA-3D printing includes the following steps:

[0048] (1) Preparation of composite ceramic powder: 800g Al 2 o 3 , 200g ZrO 2 (particle size 0.02-5μm, purity 99.9%), 30g stearic acid (SA, chemically pure), 1500g ethanol (purity 99.5%) were mixed, ball milled for 10h, vacuum dried and sieved to obtain alumina / zirconia composite Ceramic powder, spare.

[0049] (2) Preparation of organic solution containing photosensitive resin: get prepolymer (ditrimethylolpropane acrylate) 35.2g, reactive diluent (propoxylated neopentyl glycol diacrylate) 140.8g, photoinitiator (1 -Hydroxycyclohexyl phenyl ketone) is 5% of the total mass of reactive diluent and prepolymer; the above photoinitiator, reactive diluent and prepolymer are placed in a beaker, and ultrasonically dispersed at 40 ° C for 2 hours to obtain a photosensitive Resin: 20 g of plasticizer (di...

Embodiment 2

[0053] A homogeneous preparation technology of zirconia / alumina composite photosensitive paste based on SLA-3D printing, including the following steps: (1) Preparation of composite ceramic powder: 500g Al 2 o 3 , 500g ZrO 2 (particle size 0.02-5μm, purity 99.9%), 10g oleic acid (OA, chemically pure), 2000g ethanol (purity 99.5%) were mixed, ball milled for 30 hours, vacuum dried and sieved to obtain alumina / zirconia composite ceramics Powder, spare.

[0054] (2) Preparation of organic solution containing photosensitive resin: get prepolymer (ethoxylated pentaerythritol tetraacrylate) 266.6g, reactive diluent (1,6-hexanediol diacrylate) 66.6g, photoinitiator (α- Hydroxyalkyl phenone) is 2% of reactive diluent and prepolymer gross mass; Above-mentioned photoinitiator, reactive diluent and prepolymer are placed in beaker, 0.5h is ultrasonically dispersed at 30 ℃, obtains photosensitive resin; Then, 1 g of plasticizer (phthalate), 5 g of polyoxyethylene polyoxypropanolamine eth...

Embodiment 3

[0058] A zirconia / alumina composite photosensitive paste homogenization preparation technology based on SLA-3D printing, comprising the following steps:

[0059] (1) Preparation of composite ceramic powder: 990g Al 2 o 3 , 100g ZrO 2 (particle size 0.02-5μm, purity 99.9%), 3g polyester polyol (chemically pure), 2000g ethanol (purity 99.5%) mixed, ball milled for 30h, dried in vacuum and sieved to prepare alumina / zirconia composite ceramics Powder, spare.

[0060] (2) Preparation of organic solution containing photosensitive resin: get prepolymer (ethoxylated trimethylolpropane triacrylate) 50.3g, reactive diluent (dipropylene glycol diacrylate) 75.6g, photoinitiator (benzoin bismethacrylate) ether) is 3% of the total mass of reactive diluent and prepolymer; the above-mentioned photoinitiator, reactive diluent and prepolymer are placed in a beaker, and are ultrasonically dispersed at 50°C for 1.5h to obtain a photosensitive resin; then plasticized Agent (phthalate) 1g, poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com