HCG mirror layer, vertical cavity surface emitting laser, and preparation methods thereof

A technology of vertical cavity surface emission and mirrors, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as difficult to achieve scale, reduce production costs, and complex VCSEL epitaxial structure, so as to reduce production costs and maintain polarization The effect of good performance and wide reflection bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

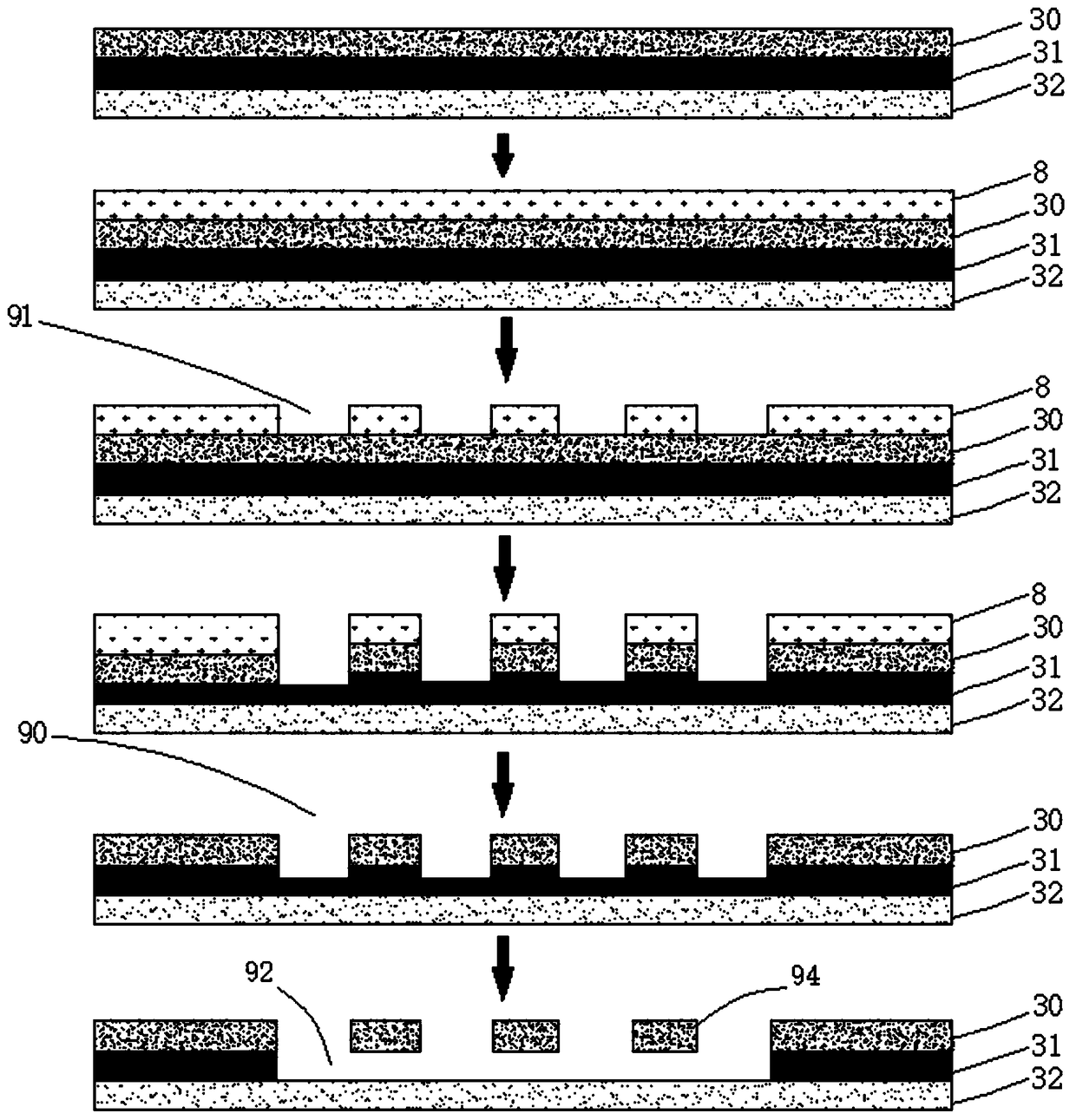

[0040] see image 3 , the embodiment of the present invention provides an HCG reflector layer, comprising an indium gallium arsenide layer 32 grown sequentially, a first multi-quantum well active layer 31 and an indium phosphide layer 30, and the HCG reflector layer also includes an indium phosphide layer formed on the The air suspension grating structure on the indium phosphide layer 30 and the first multiple quantum well active layer 31, the air suspension grating structure includes the active A groove recessed in the direction of layer 31 and a sub-wavelength grating 94 suspended in said groove. In this embodiment, the air suspension grating structure is obtained by processing the indium phosphide layer 30 and the first multi-quantum well active layer 31. The processing method is usually etching, and the indium phosphide layer 30 and the first multi-quantum well After the active layer 31, a groove will be formed, and it is preferable to etch the InGaAs layer 32 during etch...

Embodiment 2

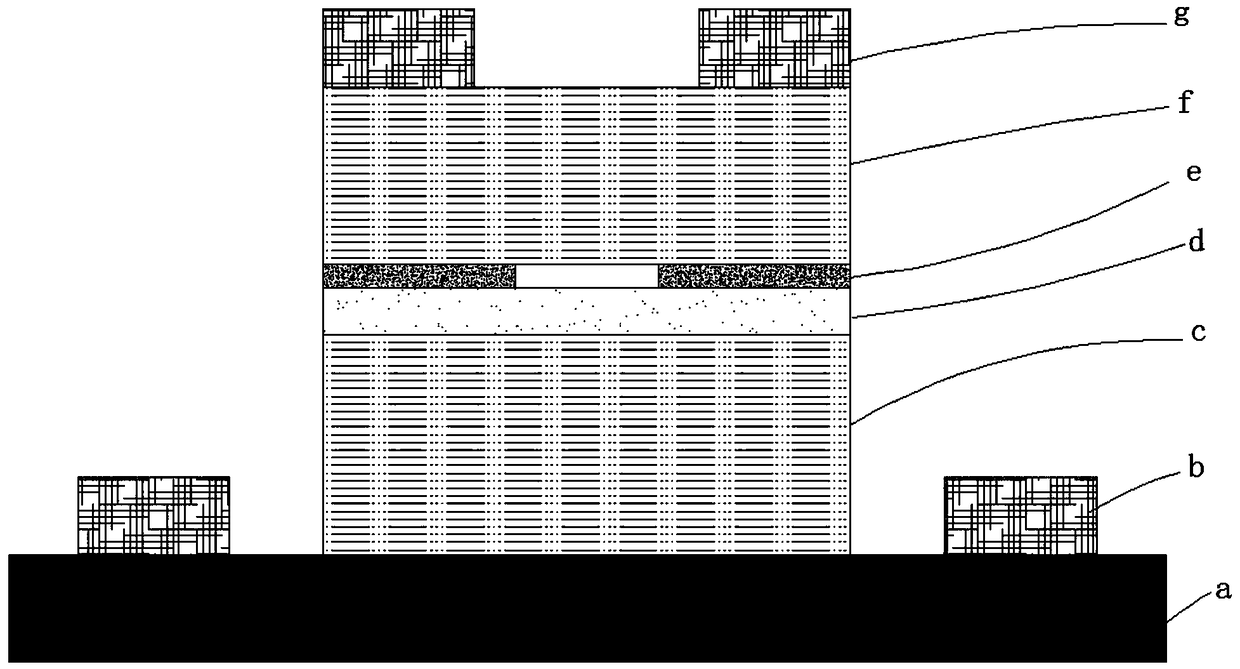

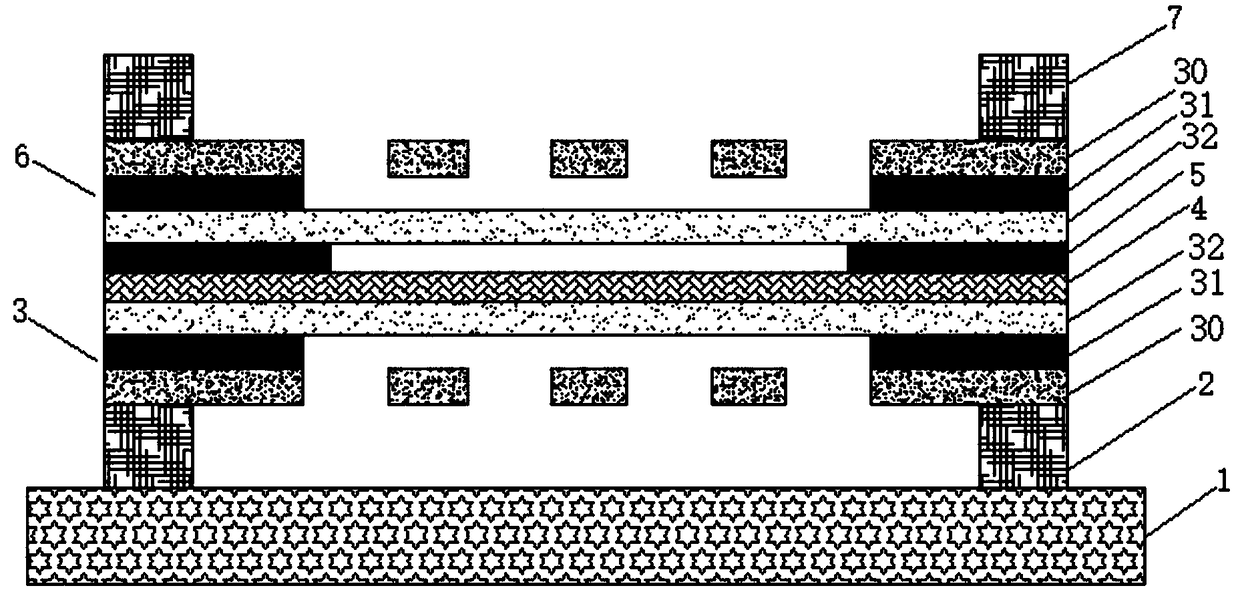

[0043] see Figure 2-3 , an embodiment of the present invention provides a vertical cavity surface emitting laser, including a ceramic spacer 1 and the above-mentioned HCG mirror layer, and the two HCG mirror layers are respectively the first HCG mirror layer 3 and the second HCG mirror layer 6. An n-type electrode layer 2, a first HCG mirror layer 3, a second multi-quantum well active layer 4, a confinement layer 5, a second HCG mirror layer 6, and a p-type electrode layer are sequentially grown on the ceramic spacer 1. electrode layer 7, the indium phosphide layer 30 of the first HCG mirror layer 3 is close to the n-type electrode layer 2, and the indium phosphide layer 30 of the second HCG mirror layer 6 is close to the p-type electrode layer 7 . In this embodiment, after removing the ceramic spacer 1, the n-type electrode layer 2 and the first HCG mirror layer 3 are symmetrical to the second HCG mirror layer 6 and the p-type electrode layer 7, and the symmetry line is the...

Embodiment 3

[0047] This embodiment can prepare the HCG reflector layer in the above-mentioned embodiment one, and this embodiment is interrelated with embodiment one, please refer to image 3 , an embodiment of the present invention provides a method for preparing an HCG mirror layer, S1, sequentially growing an indium gallium arsenic layer 32, a first multi-quantum well active layer 31, and an indium phosphide layer 30; S2, sequentially processing the indium gallium arsenic layer Arsenic layer 32, the first multi-quantum well active layer 31 and the indium phosphide layer 30 to obtain an air-suspended grating structure, and in the obtained air-suspended grating structure, the air-suspended grating structure comprises A groove that is depressed from the indium phosphide layer 30 to the first multi-quantum well active layer 31 and a sub-wavelength grating 94 suspended in the groove. In this embodiment, the air suspension grating structure is obtained by processing the indium phosphide laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com