A method for preparing magnetic graphene films based on chemical vapor deposition

A technology of chemical vapor deposition and magnetic graphene, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of cumbersome process, doping of impurity atoms, etc., and achieve great application potential and surface morphology adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

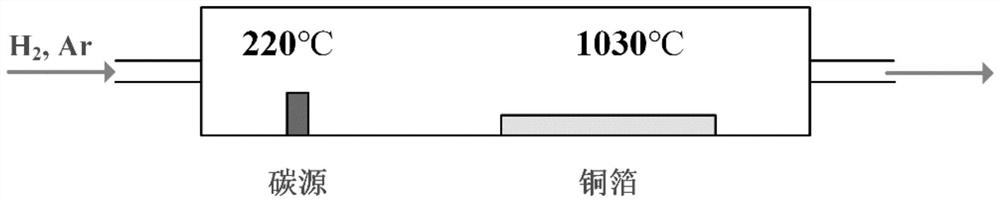

[0039] Such as figure 1 As shown, a copper foil is provided in the reaction chamber, and at the same time, a carrier gas containing hydrogen and argon mixed gas is passed through the reaction chamber, and a solid carbon source is placed at the inlet end of the reaction chamber.

[0040] (1) Select copper foil (Alfa Aesar, 99.8% purity, 25μm thickness), soak it in acetic acid for 8-10 hours, then soak it in acetone for 20-30 minutes, and finally clean it with isopropanol.

[0041] (2) Put the solid carbon source ferrocene powder into a quartz cup located at one end of the gas source.

[0042] (3) Pass 10% H 2 / Ar mixed gas, the flow rate is 400sccm, and the copper foil is annealed at 1050°C for 1h. Then adjust the air flow to 600 sccm, and keep the copper foil temperature at 1030°C. Then heat the polystyrene so that its temperature rises linearly at 160-190° C. at a rate of 0.75° C. / min to complete the volatilization control of the amount of carbon source. After 40min of de...

Embodiment 2

[0049] In order to better control the volatilization concentration of the carbon source, the quartz cup containing the ferrocene powder was packaged with copper foil to limit the volatilization area and gas outlet aperture of the carbon source. Then the gas flow after the annealing of the copper foil in Example 1 was adjusted to 700 sccm, and the temperature of the copper foil was kept at 1030° C. unchanged. At the same time, the carbon source ferrocene was heated to 220° C., and after 30 minutes of deposition, the iron-doped graphene was prepared. Then repeat the process of embodiment 1. By controlling the deposition time, the growth process of iron-doped graphene samples from hexagonal domains to continuous films can be observed.

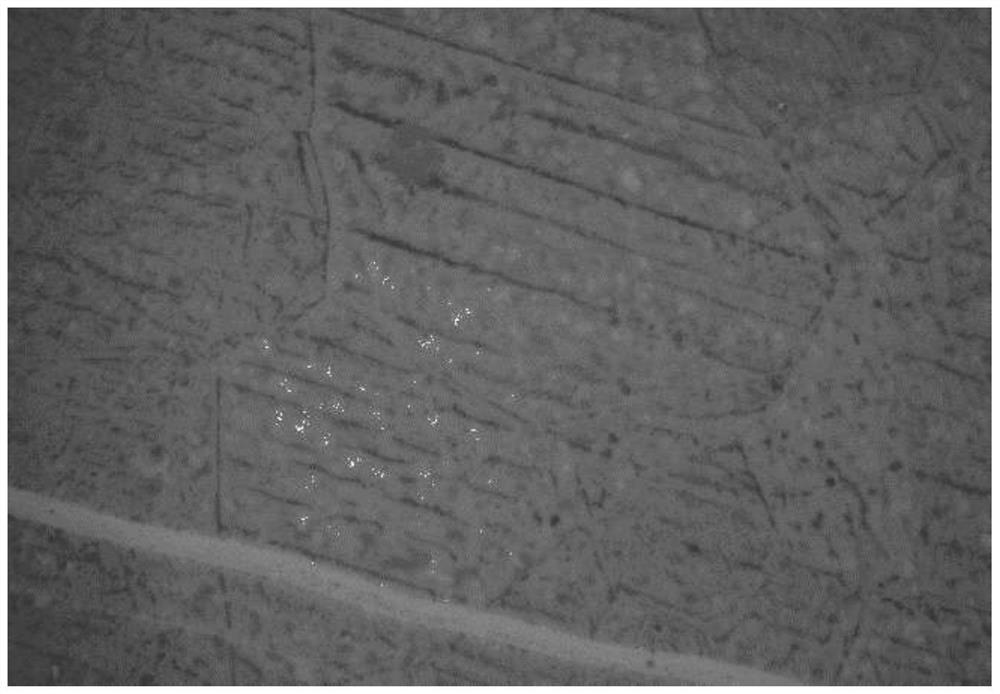

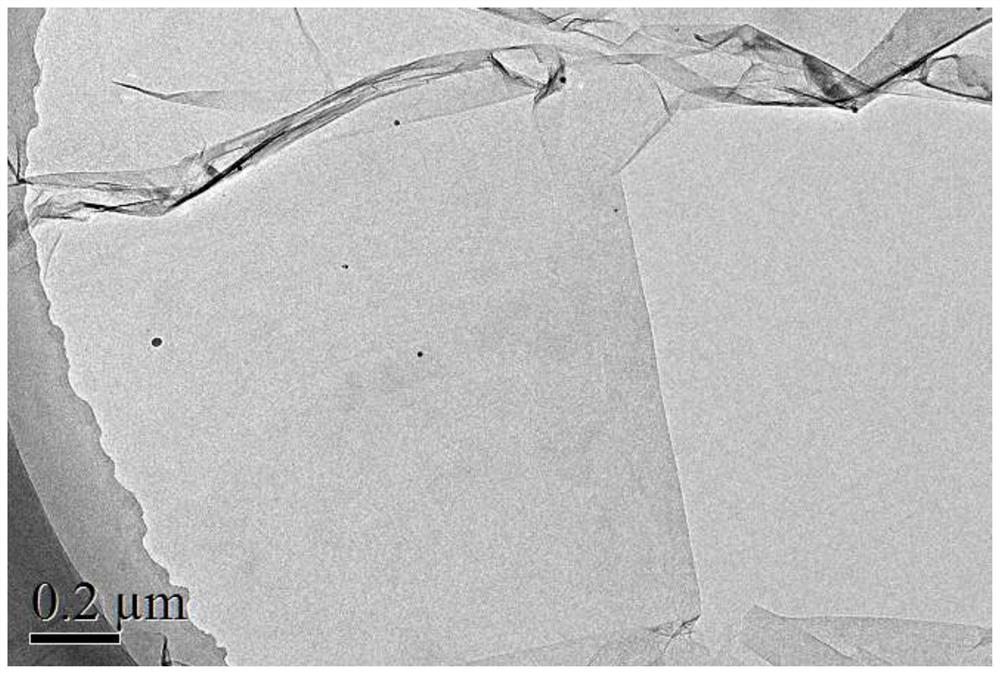

[0050] Example results: the prepared iron-doped graphene is a uniform few-layer graphene, and the Raman spectrum is as follows Figure 5 shown. Scanning electron micrographs of hexagonal graphene domains visualized on copper foil, as Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com