Preparation method of bi-pass large-area TiO2 nanotube array film

A nanotube array and large-area technology, applied in the field of biochemistry, can solve the problems of narrow pore size distribution range, difficult control of pore structure and arrangement, and achieve good biocompatibility, high photoelectric conversion efficiency, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

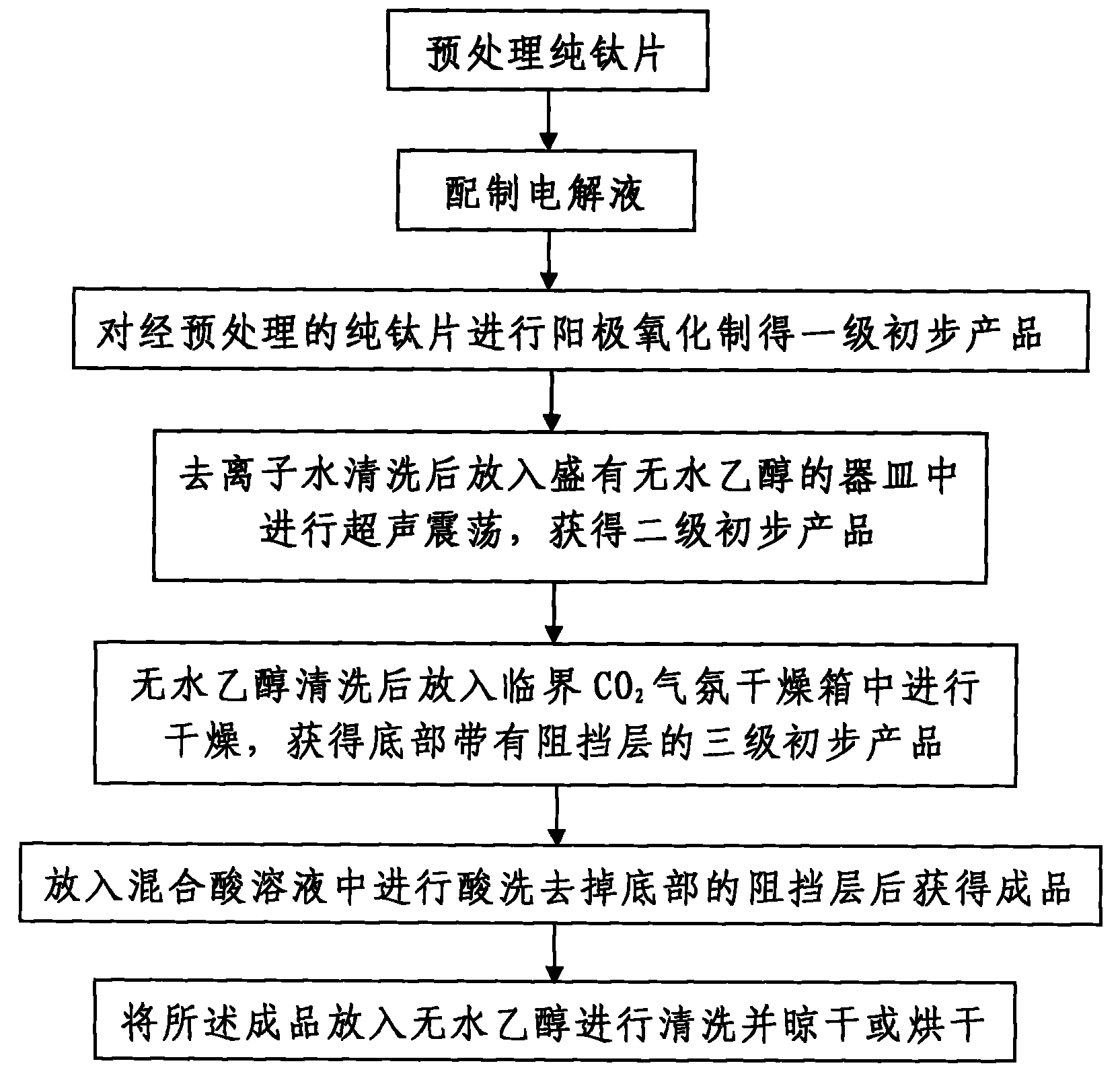

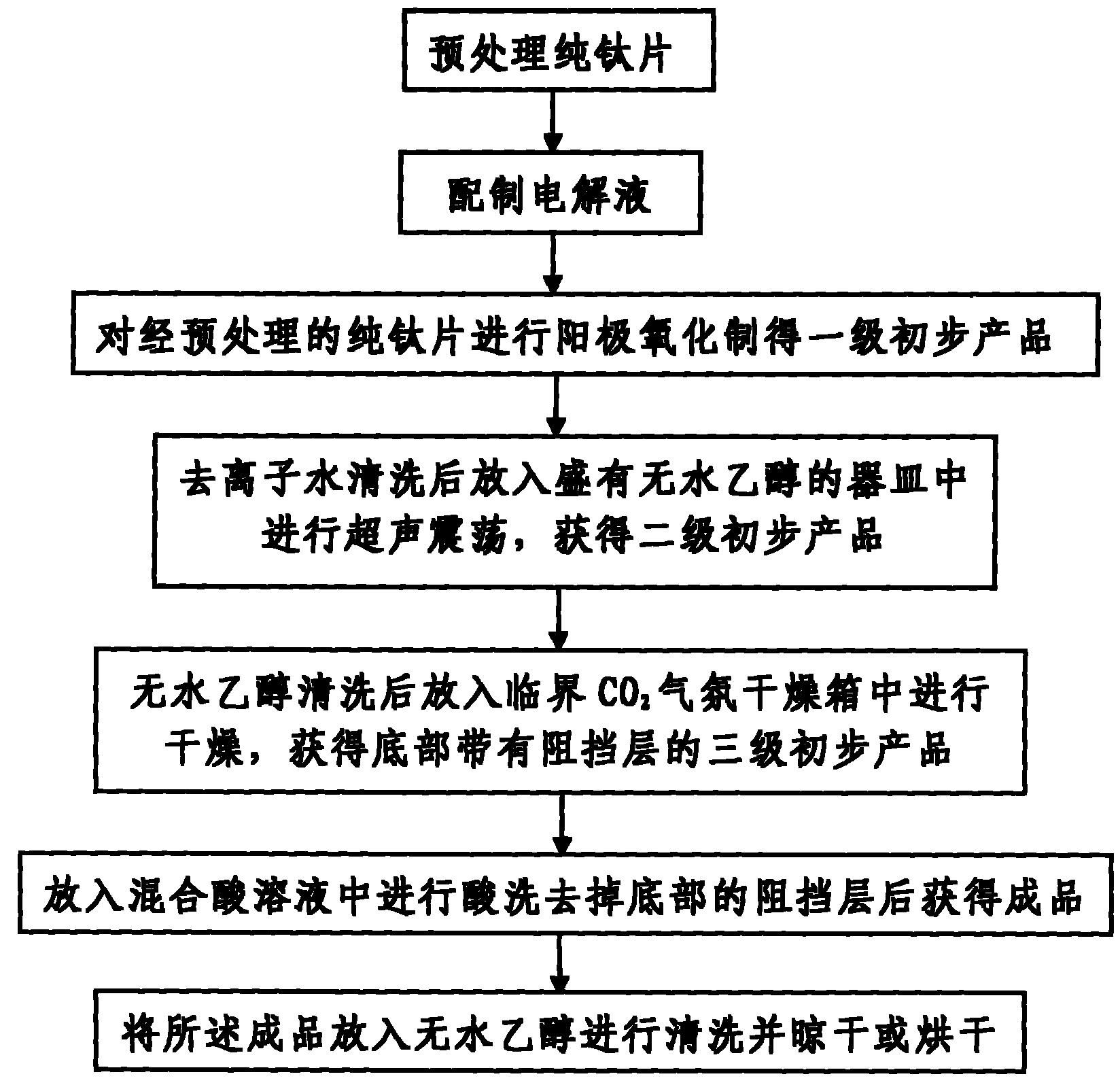

[0022] Such as figure 1 As shown, the double-pass large-area TiO described in the present invention 2 A method for preparing a nanotube array film, comprising the following steps:

[0023] Step 1, anodic oxidation is carried out to the pretreated pure titanium sheet, and it comprises the following steps:

[0024] (1) Pretreatment of pure titanium sheet: the oxide layer on the surface of the pure titanium sheet to be treated is removed by conventional mechanical processing. The pure titanium sheet is a flat sheet with a thickness of 0.1-0.5 mm. In this step, the pretreated pure titanium sheet is a rectangular sheet. After removing the oxide layer on the surface of the pure titanium sheet to be treated, the treated pure titanium sheet is ultrasonically cleaned with deionized water, ethanol and acetone in sequence by an ultrasonic cleaner and dried in an oven.

[0025] In this example, the industrial pure titanium sheet is mechanically polished with 600# and 1000# water abrasi...

Embodiment 2

[0037] In this embodiment, the pure titanium sheet pretreated in step (1) is a rectangular sheet with a size of 100 mm×26 mm×0.3 mm. In step (3), when the pretreated pure titanium sheet is placed in the electrolytic solution for electrolytic oxidation reaction, the stainless steel foil electrode is used as the cathode, the voltage of the DC power supply used is 70V, and the oxidation temperature is 10-70°C. The time is 30h. When performing ultrasonic oscillation in step 2, the oscillation time is 0.2h. When the mixed acid solution is used to remove the barrier layer in step 4, the acidification time is 0.3-0.5 h. In this embodiment, the rest of the process steps and process parameters are the same as those in Example 1.

Embodiment 3

[0039] In this embodiment, the anhydrous organic solvent for preparing the electrolyte solution in step (2) is ethylene glycol, and the solute is NH 4 F, and the volume ratio of ethylene glycol and water is 97:3, NH 4 The mass ratio of F to the prepared electrolyte is 1.0%. The pure titanium sheet pretreated in step (1) is a rectangular sheet with a size of 100mm×26mm×0.3mm. In step (3), when the pretreated pure titanium sheet is placed in the electrolyte for electrolytic oxidation reaction, the stainless steel foil electrode is used as the cathode, the voltage of the DC power supply used is 30V, the oxidation temperature is room temperature, and the oxidation time is 70h . When performing ultrasonic oscillation in step 2, the oscillation time is 0.2h. When the mixed acid solution is used to remove the barrier layer in step 4, the acidification time is 0.4-0.5 h. In this embodiment, the rest of the process steps and process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com