Cold spraying reinforcing material repairing material and repairing method of worn Roots blower cover plate

A technology for Roots blower and repair material, which is applied in the directions of coating, additive processing, and devices for coating liquid on the surface, etc., which can solve the problems such as the decrease of the sealing performance of the cover plate, the deformation of the cover plate of the Roots blower, and the limitation of the thickness of the coating layer. , to achieve the effect of improving bonding strength, eliminating pores and residual stress, and promoting full diffusion and alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The cold spray additive material repairing of the worn Roots blower cover plate is made of Ni60 copper-zinc powder, which is prepared from the following raw materials in mass percentage:

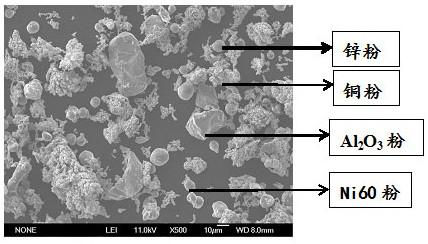

[0026] Ni60 55%-65%, Cu powder 24%-32%, Zn powder 6%-8%, Al 2 o 3 Powder 3%-5%, the sum of the mass percentages of each component is 100%; the Ni60, Cu, Zn powder and Al 2 o 3 The particle size range of the powder is 10-40μm; the shape of Ni60 and Cu powder is spherical, the shape of Zn powder is dendritic, and the shape of Al 2 o 3 Powder is α-phase Al with polygonal shape 2 o 3 Powder, the Ni60 copper-zinc-based powder is mechanically mixed for 4 hours according to the above ratio until uniform.

[0027] The cold-spray additive material repair process method of worn Roots blower cover plate, its repair process, comprises the steps:

[0028] (1) Pretreatment before cold spray repair of worn Roots blower cover plate, use brown corundum with a particle size of 0.5-1mm to carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com