Release film for circuit board

A circuit board and release film technology, which is applied in applications, household appliances, electronic equipment, etc., can solve the problems of copper foil removal and high production cost, and achieve the effects of improved heat sealing performance, improved mechanical properties, and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

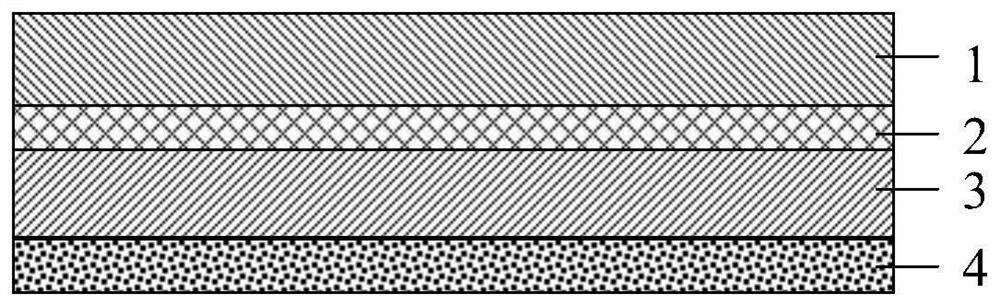

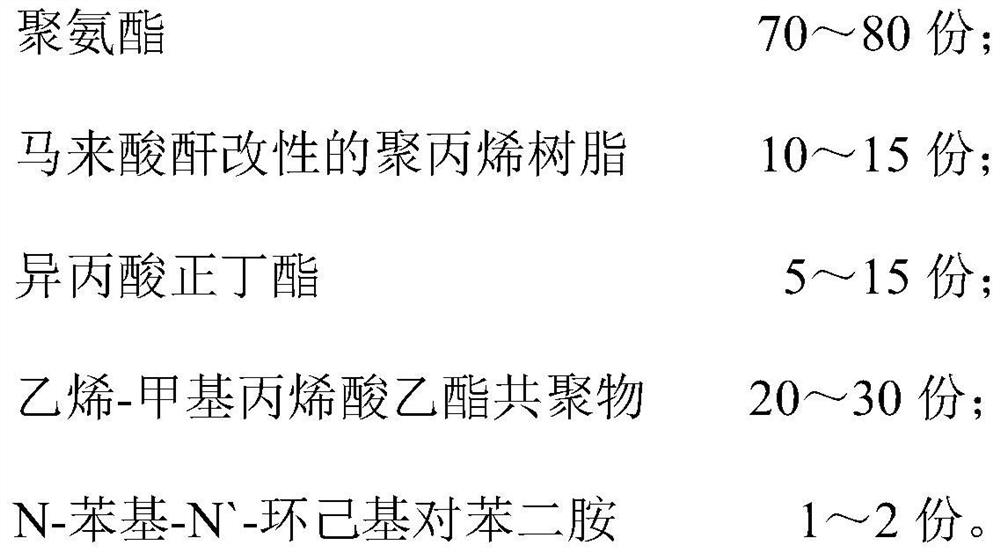

[0036] This embodiment provides a release film for a circuit board, such as figure 1 As shown, it includes a support layer 1 , an adhesive layer 2 , an aluminum foil layer 3 and a release heat-sealing layer 4 which are stacked in sequence.

[0037] The support layer 1 is a biaxially stretched polyester film with a thickness of 18 μm. The support layer 1 has high strength, which is beneficial to the curing and molding of the release film.

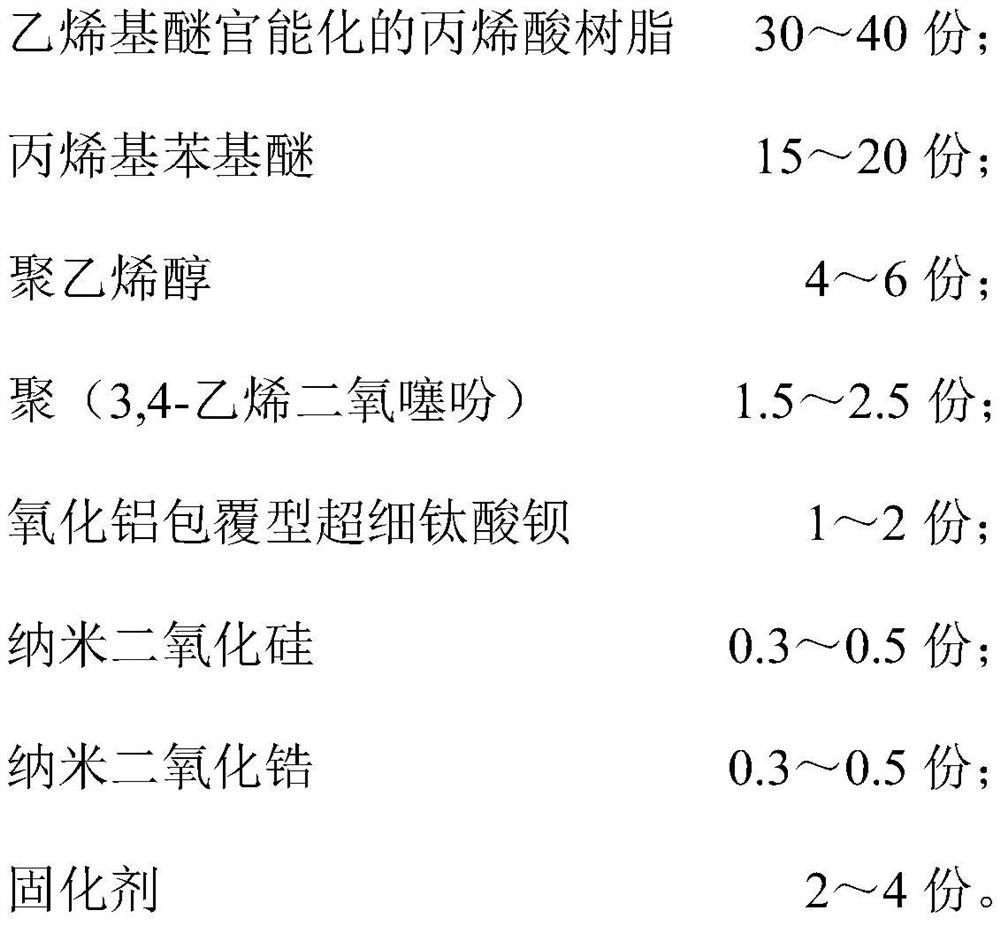

[0038] The adhesive layer 2 includes 75 parts by weight of polyurethane, 12.5 parts by weight of polypropylene resin modified by maleic anhydride, 10 parts by weight of n-butyl isopropionate, 25 parts by weight of ethylene-ethyl methacrylate copolymer, N-phenyl -N`-cyclohexyl-p-phenylenediamine 1.5 parts by weight.

[0039] Wherein, in the ethylene-ethyl methacrylate copolymer, the content of ethylene is 22.5 wt %; the thickness of the adhesive layer 2 is 4 μm.

[0040] Adding maleic anhydride-modified polypropylene resin and ethylene-ethy...

Embodiment 2

[0051] This embodiment provides a release film for a circuit board, such as figure 1 As shown, it includes a support layer 1 , an adhesive layer 2 , an aluminum foil layer 3 and a release heat-sealing layer 4 which are stacked in sequence.

[0052] The support layer 1 is a biaxially stretched polyester film with a thickness of 12 μm.

[0053] The adhesive layer 2 comprises 80 parts by weight of polyurethane, 10 parts by weight of polypropylene resin modified by maleic anhydride, 15 parts by weight of n-butyl isopropionate, 30 parts by weight of ethylene-ethyl methacrylate copolymer, N-phenyl -1 part by weight of N'-cyclohexyl-p-phenylenediamine.

[0054] Wherein, in the ethylene-ethyl methacrylate copolymer, the content of ethylene is 25 wt %; the thickness of the adhesive layer is 3 μm.

[0055] The aluminum foil layer 3 is made of H-state aluminum foil with a thickness of 20 μm. The surface of the aluminum foil layer 3 facing the release heat-sealing layer 4 is a roughene...

Embodiment 3

[0062] This embodiment provides a release film for a circuit board, such as figure 1 As shown, it includes a support layer 1 , an adhesive layer 2 , an aluminum foil layer 3 and a release heat-sealing layer 4 which are stacked in sequence.

[0063] The supporting layer 1 is a biaxially stretched polyester film with a thickness of 25 μm.

[0064] The adhesive layer 2 comprises 70 parts by weight of polyurethane, 15 parts by weight of polypropylene resin modified by maleic anhydride, 5 parts by weight of n-butyl isopropionate, 20 parts by weight of ethylene-ethyl methacrylate copolymer, N-phenyl -N`-cyclohexyl-p-phenylenediamine 2 parts by weight.

[0065] Wherein, in the ethylene-ethyl methacrylate copolymer, the content of ethylene is 20 wt %; the thickness of the adhesive layer is 5 μm.

[0066] The aluminum foil layer 3 is made of H-state aluminum foil with a thickness of 30 μm. The surface of the aluminum foil layer 3 facing the release heat-sealing layer 4 is a roughene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com