One-step forming and blistering process for the bottom plate of a refrigerator compressor box

A refrigerator compressor and box body technology, which is applied to other household appliances, household components, household appliances and other directions, can solve the problems of complex processing technology, leakage of bubbles at the edge of the gap, high mold cost, etc., and achieves simple preparation technology and impact resistance performance. Stable, hot melt stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

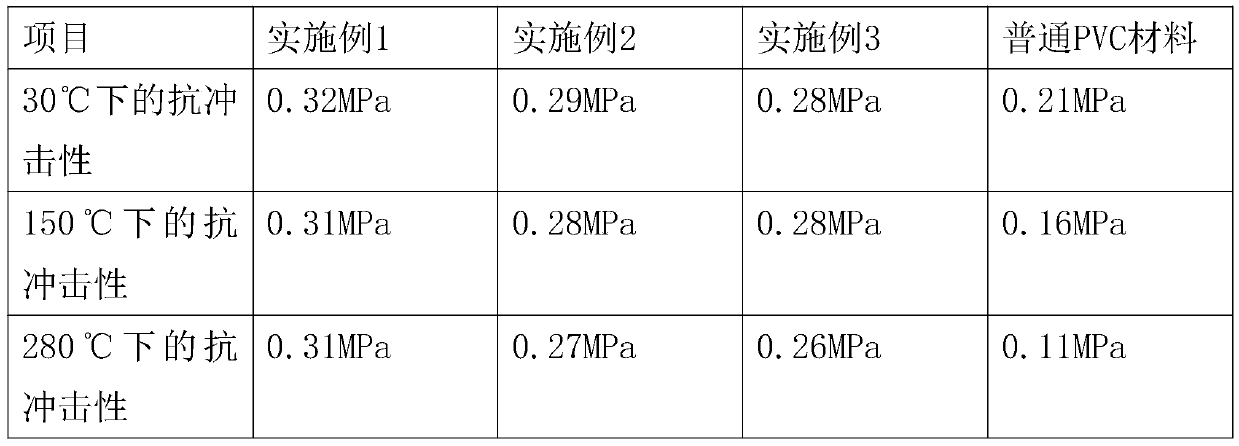

Examples

Embodiment 1

[0018] A one-time molding and blistering process for the bottom plate of a refrigerator compressor box, comprising the following steps:

[0019] (1) The flame retardant material is mixed and extruded by a screw extruder to obtain a hard sheet; the extrusion speed of the sheet in the screw extruder is 0.1-0.2 m / min;

[0020] (2) Heat the plastic sheet to 55°C through a heating box, cool the sheet to 10°C with nitrogen after holding the heat for 2 minutes, and then spray atomized ethanol on the surface of the sheet to make the surface humidity of the sheet uniform;

[0021] (3) The sheet is heated to 55°C again, and then the sheet is blistered to obtain the bottom plate of the refrigerator compressor box.

[0022] The flame retardant material includes the following components, and the weight percentages of each component are as follows: PVC resin 74%, C-PVC resin 12%, kaolin 4%, modified ACR 2%, dioctyl phthalate 1%, talcum powder 1% , heat stabilizer 1%, auxiliary agent 4%, mo...

Embodiment 2

[0024] A one-time molding and blistering process for the bottom plate of a refrigerator compressor box, comprising the following steps:

[0025] (1) The flame retardant material is mixed and extruded by a screw extruder to obtain a hard sheet; the extrusion speed of the sheet in the screw extruder is 0.1-0.2 m / min;

[0026] (2) Heat the plastic sheet to 55°C through a heating box, cool the sheet to 10°C with nitrogen after holding the heat for 2 minutes, and then spray atomized ethanol on the surface of the sheet to make the surface humidity of the sheet uniform;

[0027] (3) The sheet is heated to 55°C again, and then the sheet is blistered to obtain the bottom plate of the refrigerator compressor box.

[0028] The flame retardant material includes the following components, and the weight percentages of each component are as follows: PVC resin 72%, C-PVC resin 10%, kaolin 7%, modified ACR 1%, dioctyl phthalate 2%, talcum powder 2% , heat stabilizer 2%, additives 3%, modified...

Embodiment 3

[0030] A one-time molding and blistering process for the bottom plate of a refrigerator compressor box, comprising the following steps:

[0031] (1) The flame retardant material is mixed and extruded by a screw extruder to obtain a hard sheet; the extrusion speed of the sheet in the screw extruder is 0.1-0.2 m / min;

[0032] (2) Heat the plastic sheet to 55°C through a heating box, cool the sheet to 10°C with nitrogen after holding the heat for 2 minutes, and then spray atomized ethanol on the surface of the sheet to make the surface humidity of the sheet uniform;

[0033] (3) The sheet is heated to 55°C again, and then the sheet is blistered to obtain the bottom plate of the refrigerator compressor box.

[0034] The flame retardant material includes the following components, and the weight percentages of each component are as follows: PVC resin 76%, C-PVC resin 14%, kaolin 2%, modified ACR 1%, dioctyl phthalate 1%, talcum powder 1% , heat stabilizer 1%, auxiliary agent 3%, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com