Tiny laval hole micro electrode electric spark machining device and assembling and machining method

A technology of micro-electrodes and processing devices, which is applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., and can solve the problems of poor hole precision and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] In order to further illustrate the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

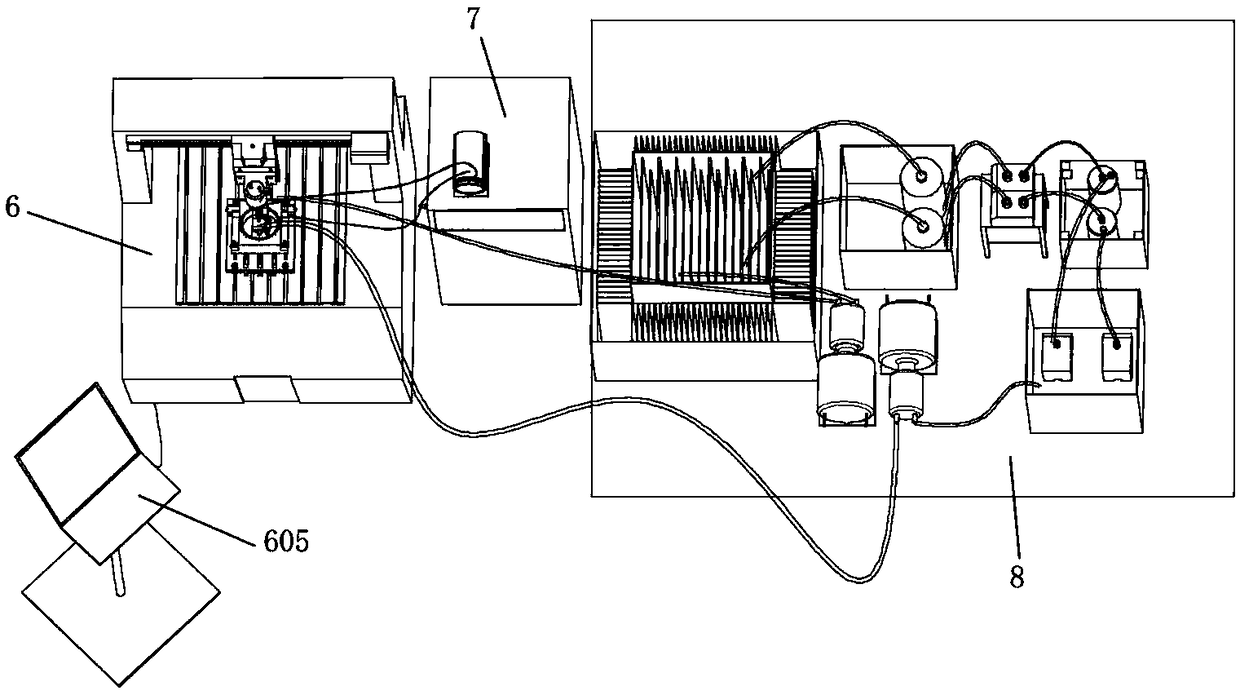

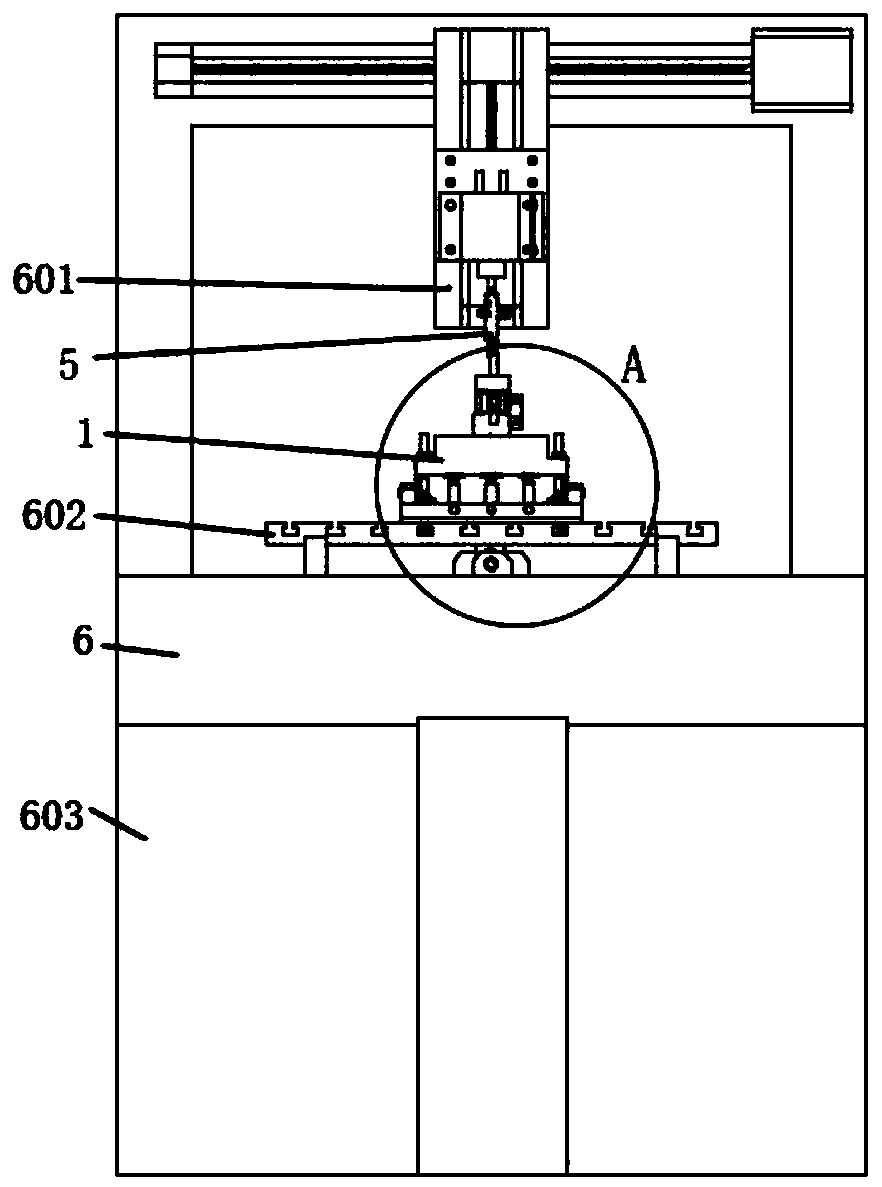

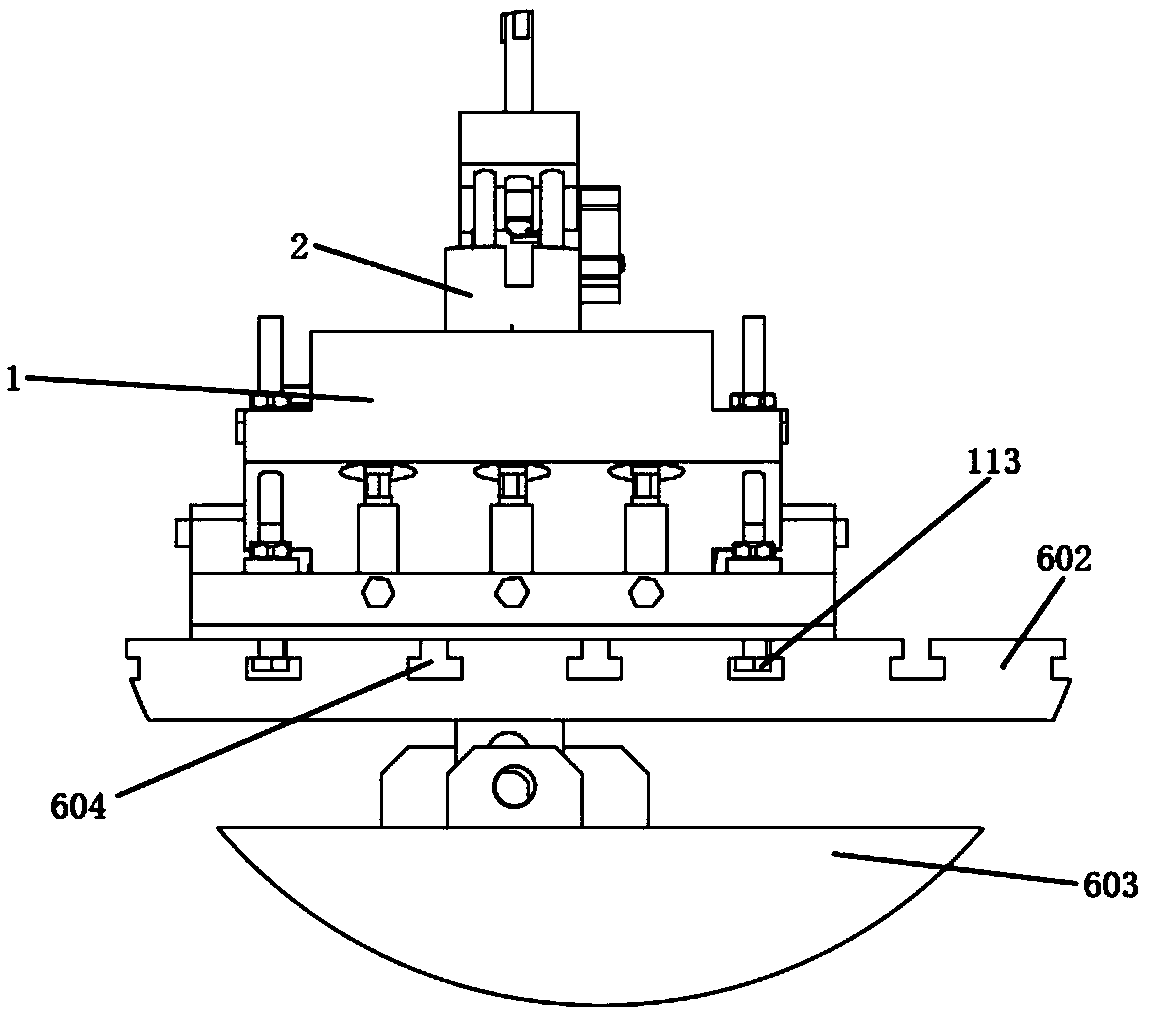

[0093] like Figure 1 to Figure 25 As shown, the micro Laval hole micro electrode EDM device also includes a device base 1, a Y-axis rotary table 2, a Z-axis rotary table 3, a fuel injection nozzle fixture assembly 4, an oil supply and power supply electrode assembly 5, and a three-axis numerical control Machine tool 6, EDM pulse power supply 7 and high-voltage EDM oil delivery system 8. The three-axis CNC machine tool 6 is composed of a machine tool spindle 601, a machine tool workbench 602, a machine tool body 603, and an operating table 605. On the machine tool workbench 602 T-shaped slot 604 is provided;

[0094] The device abutment 1 comprises two bolts 104, three bottom plate ball-socket top screws 105, an abutment bottom plate 106, a rotary table 108, three slide blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com