Metamaterial

A technology of metamaterials and dielectric layers, applied in the field of metamaterials, can solve the problems of difficult operation, complex structure, increased structural complexity, etc., and achieve the effect of continuous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] Such as figure 2 As shown, the annular metal sheet 6 is provided with a first opening 7, so that the metal microstructure 1 is a C-shaped metal microstructure, and at the same time, the center of the annular metal sheet 6 coincides with the center of the first dielectric layer 4 . In addition, the C-type metal microstructure on the upper and lower surfaces of the electrically controllable metamaterial unit and the reflective layer 5 are used to apply a bias voltage to form a bias electric field, thereby controlling the dielectric constant of the liquid crystal material by controlling the voltage between the metal on the upper and lower surfaces. Thereby changing the resonant frequency of the antenna, and recording the change of the resonant frequency of the metamaterial when the dielectric constant changes, and drawing the frequency-permittivity curve, in addition, although figure 1 It is only shown that there is a first opening 7 on the ring metal sheet, but those of...

no. 2 example

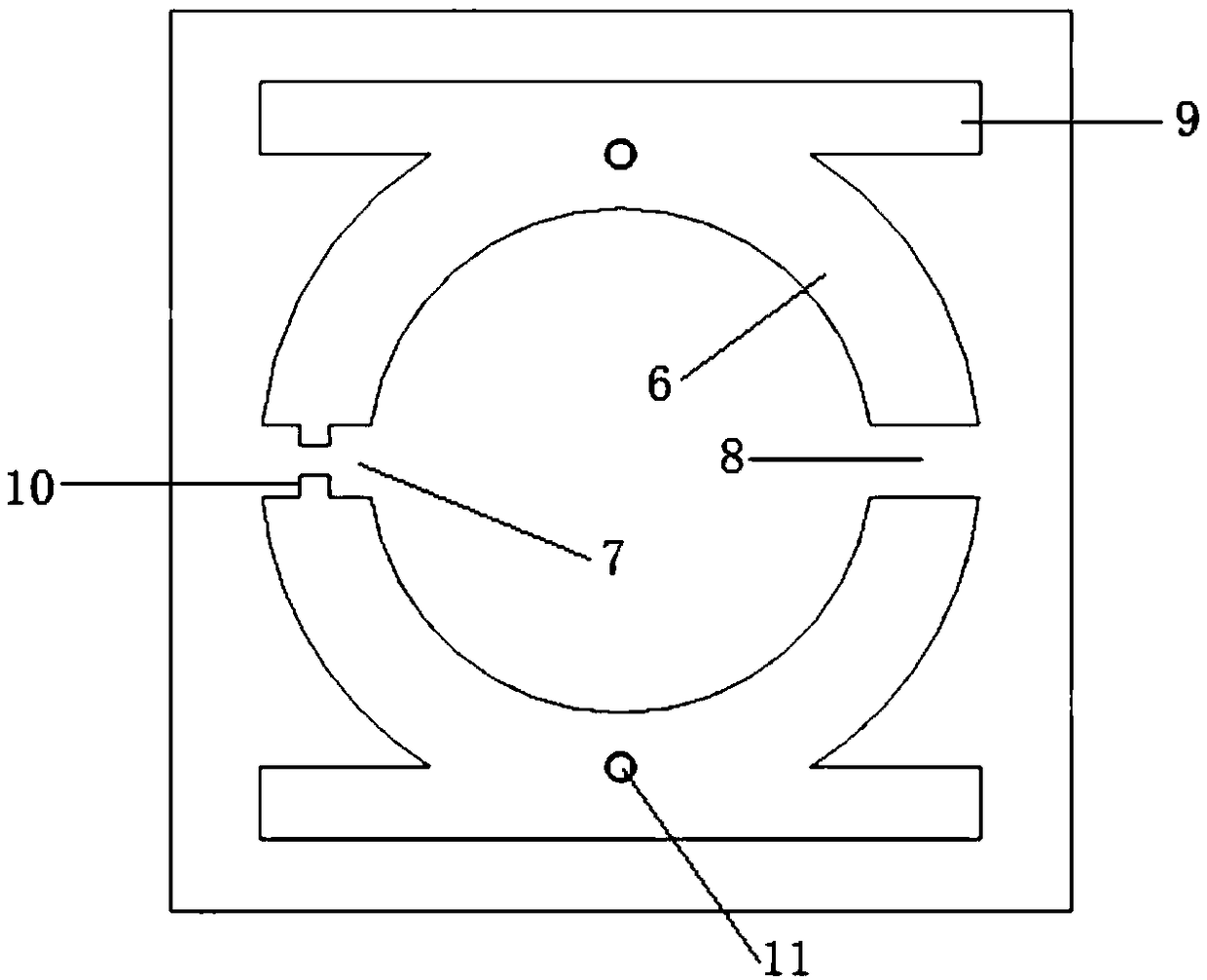

[0046] Such as image 3 As shown, the metal microstructure 1 is a double K-shaped metal microstructure, and the double K-shaped metal microstructure is composed of two K-shaped metal sheets, and the above-mentioned two K-shaped metal sheets are arranged symmetrically with respect to the horizontal axis. And each K-shaped metal sheet includes a rectangular metal sheet 9 and an arc-shaped metal sheet. In addition, the two arc-shaped metal sheets of the double K-shaped metal microstructure can be obtained by setting the first opening 7 and the second opening 8 on the annular metal sheet 6. Of course, it can be understood that the above-mentioned two arc-shaped metal sheets are In the case of a semicircular metal sheet, the circular metal sheet can be cut in half. In addition, the above-mentioned first opening 7 or second opening 8 may also be an opening of the metal microstructure 1 .

[0047] Also, continue to see image 3, the double K-type metal microstructure also includes...

no. 1 Embodiment

[0059] Such as figure 1 and figure 2 As shown, the selected center operating frequency f range is 14GHz, the corresponding wavelength λ is 21.43mm, the material of metal microstructure 1 is copper, and the dielectric material is Rogers RT5880 gold-plated material (permittivity ε=2.2, magnetic permeability μ=1 ), and the metal microstructure 1 is a C-shaped metal sheet, the length and width of the electrically controllable metamaterial unit are equal, a=11mm is used, and the width of the metal ring is 1mm, the first opening 7 between the C-shaped metal sheets The distance between them is 1 mm, the thickness of the metal is 0.035 mm, the thickness of the first dielectric layer 4 and the second dielectric layer 2 is 0.1 mm, and the unit pitch of the metamaterial unit is 11 mm.

[0060] In addition, periodic boundary conditions are designed. When the dielectric constant of the liquid crystal material changes between 2.5-3.3, the frequency modulation is 14.65GHz-13.14GHz, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com