Method for preparing high inorganic component silicone-SiO2 hybrid coating by sol-gel method

An inorganic component and silicone technology, applied in coatings, silicon oxide, silicon dioxide, etc., can solve the problem of long-lasting resistance to atomic oxygen erosion of organic coating materials, poor bonding performance of metal materials, and resistance to vacuum ultraviolet radiation Unsatisfactory problems, such as excellent resistance to vacuum ultraviolet radiation, good resistance to atomic oxygen erosion, and good resistance to vacuum ultraviolet radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] (1) Preparation of sol

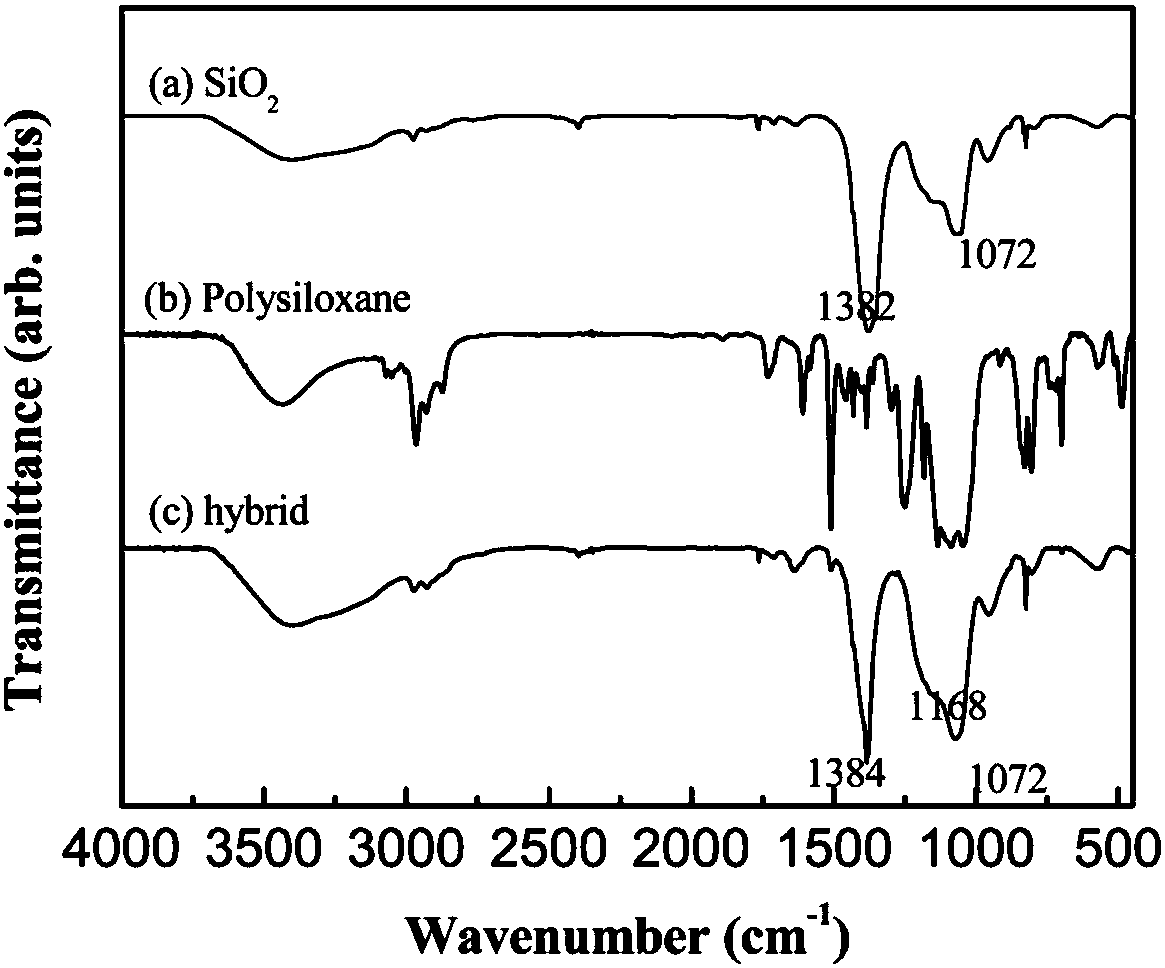

[0048] Such as Picture 9 As shown, the sol-gel method is used to prepare nano-SiO 2 60wt.% organosilicon-SiO 2 Sol method:

[0049] In the first step, tetraethylorthosilicate (TEOS) is used as the precursor to prepare nano-SiO 2 Sol: Add 5ml TEOS to 38ml of absolute ethanol (EtOH), and use magnetic stirring to quickly stir until uniform; then add 12ml of HNO with a concentration of 65wt% 3 The solution is used as a catalyst and the pH is adjusted to 2. At this time, a large amount of reaction heat is released. Then the solution was stirred vigorously at room temperature for 1 hour and then stood for 24 hours to form SiO 2 Sol is ready for use.

[0050] The second step: 0.9g of silicone resin (polysiloxane) (the amount of silicone resin selected is to hydrolyze all TEOS into SiO 2 Under the assumption of SiO 2 It is calculated by 60wt.% of the total composition) dissolved in 13ml of xylene and stirred vigorously until uniform with a magnetic stirring m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com