Nanometer hybridized ceramic resin coating as well as preparation method and application of nanometer hybridized ceramic resin coating

A ceramic resin and hybridization technology, applied in anti-corrosion coatings, fire-proof coatings, polyurea/polyurethane coatings, etc., can solve the problems of high temperature resistance performance reduction, performance loss, coating cracks, etc., to improve brittleness and weather resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

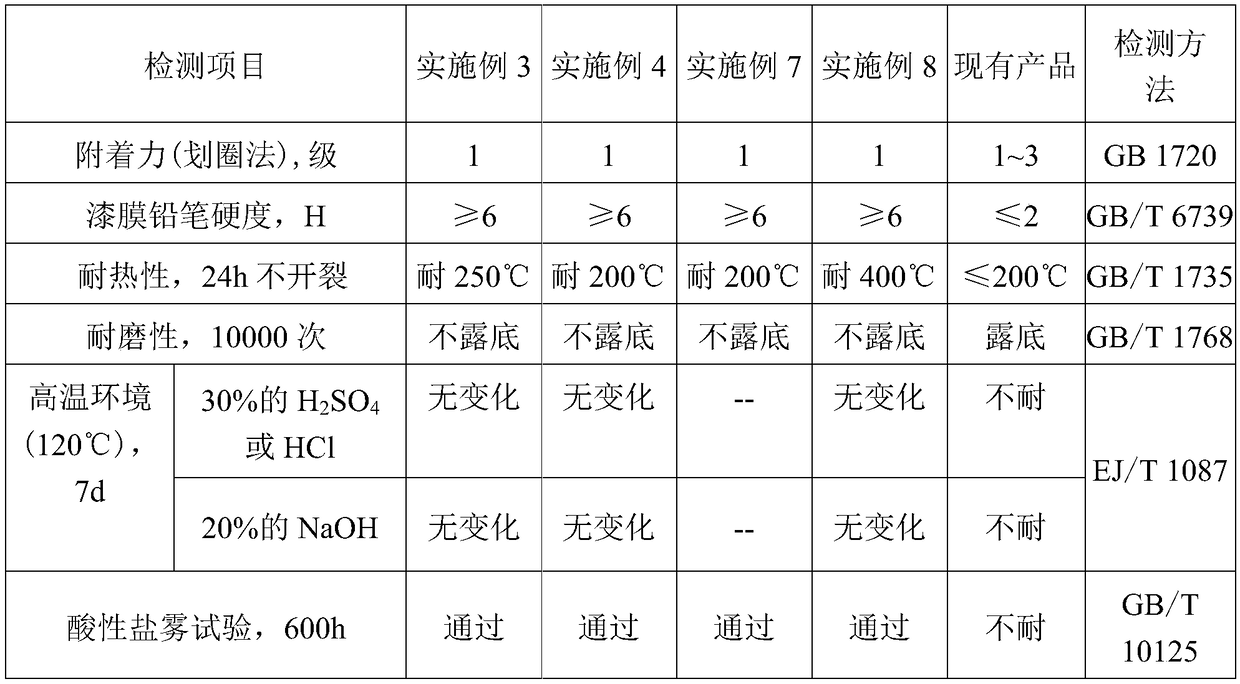

Examples

Embodiment 1

[0069] Example 1: Preparation of acid corrosion resistant ceramic paint primer under high temperature environment

[0070] According to mass parts (wt%), take 25 parts of JR180-2S water-based hydroxy polysiloxane resin, 20 parts of JY-8742 nano hybrid ceramic resin, 25 parts of 400 mesh mica iron oxide red, 10 parts of zinc phosphate, BYK-180 0.5 part of wetting and dispersing agent, 0.5 part of BD-3062 defoamer, 0.5 part of BD-2051 leveling agent, 0.5 part of Pangel S9 hydrated magnesium silicate, 0.5 part of Degussa's A200 fumed white carbon black, propylene glycol methyl ether agent 3 parts, 1 part of diacetone alcohol, 2 parts of alcohol ester-12 co-solvent, constituting component A (paint);

[0071] 25 parts of Bayhydur XP3100 aliphatic polyisocyanate water-based curing agent is selected for the cross-linked resin in parts by weight (wt%) to form component B (curing agent).

Embodiment 2

[0072] Example 2: Preparation of acid-corrosive ceramic coating intermediate paint under high temperature environment

[0073] According to mass parts (wt%), take 25 parts of JR180-2S water-based hydroxy polysiloxane resin, 20 parts of JY-8742 nano hybrid ceramic resin, 8 parts of PU-3758 water-based elastomer resin, and 25 parts of 300-400 mesh glass flakes Parts, BYK-180 wetting and dispersing agent 0.5 parts, BD-3062 defoaming agent 0.5 parts, BD-2051 leveling agent 0.5 parts, KBM-503 water-based silane coupling agent 2 parts, Degussa A200 fumed silica 0.5 part, Pangel S9 hydrated magnesium silicate 0.5 part, propylene glycol methyl ether agent 1 part, alcohol ester-12 co-solvent 2 parts, diacetone alcohol 1 part, constituting component A (paint);

[0074] As the crosslinking agent, 20 parts of Wanhua 2356 aliphatic polyisocyanate water-based curing agent were selected according to mass parts (wt%) to form component B (curing agent).

Embodiment 3

[0075] Example 3: Preparation of acid-corrosive ceramic coating topcoat under high temperature environment

[0076] The top coat is based on parts by mass (wt%), taking 25 parts of JR180-2S water-based hydroxy polysiloxane resin, 40 parts of JY-8742 nano hybrid ceramic resin, 15 parts of 400 mesh mica powder, 5 parts of barium sulfate, BYK-180 0.5 part of wetting and dispersing agent, 0.5 part of BD-3062 defoamer, 0.5 part of BD-2051 leveling agent, 0.5 part of Pangel S9 hydrated magnesium silicate, 0.5 part of Degussa's A200 fumed white carbon black, propylene glycol methyl ether agent 3 parts, 3 parts of diacetone alcohol, 3 parts of alcohol ester-12 co-solvent, composing component A (paint);

[0077] 30 parts of Aquolin 268HDI aliphatic polyisocyanate water-based curing agent is selected for the cross-linked resin in parts by weight (wt%) to form component B (curing agent).

[0078] Examples 1 to 3 are complementary products, which can be diluted with tap water and cured at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com