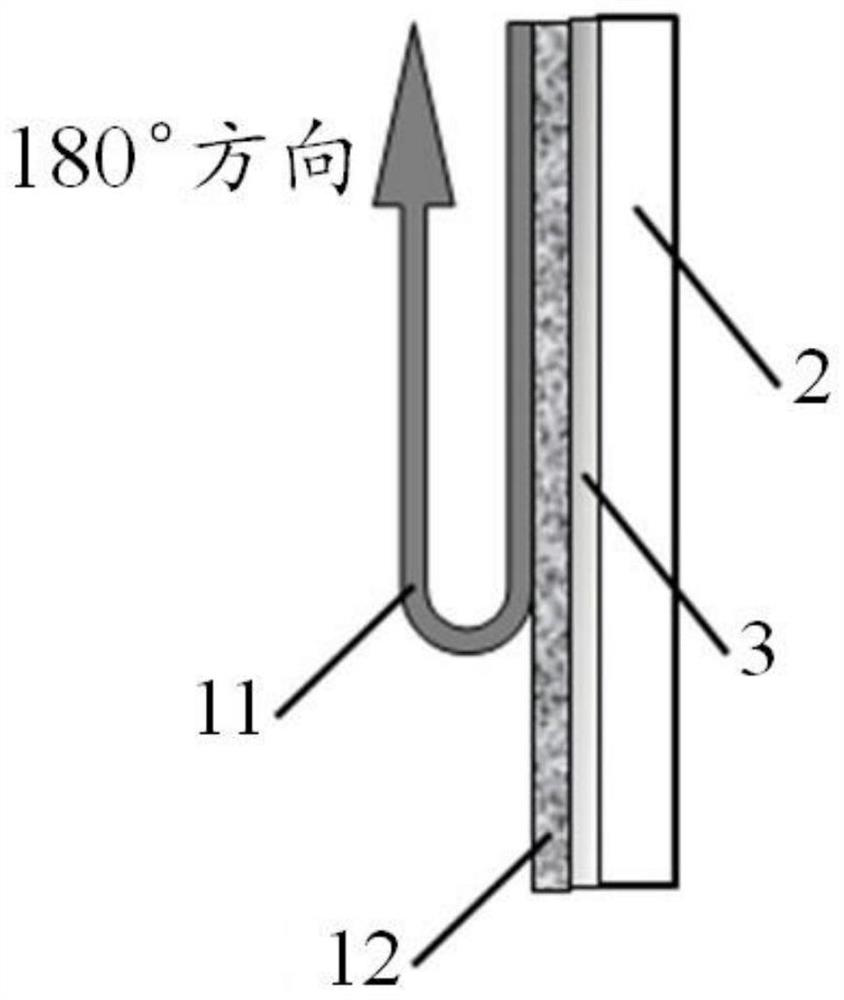

A kind of ceramic coating diaphragm and preparation method and application

A technology of ceramic coating and diaphragm, applied in coatings, structural parts, electrical components, etc., can solve the problems of the decrease of high temperature resistance of ceramic coated diaphragm, the decrease of mechanical strength of ceramic coated diaphragm, and the easy falling off of ceramic particles. Improve the overall comprehensive performance, improve the peel strength, the effect of fast liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

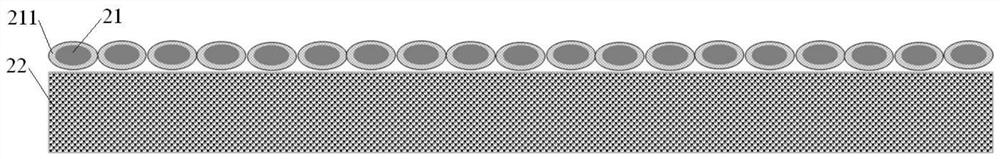

Method used

Image

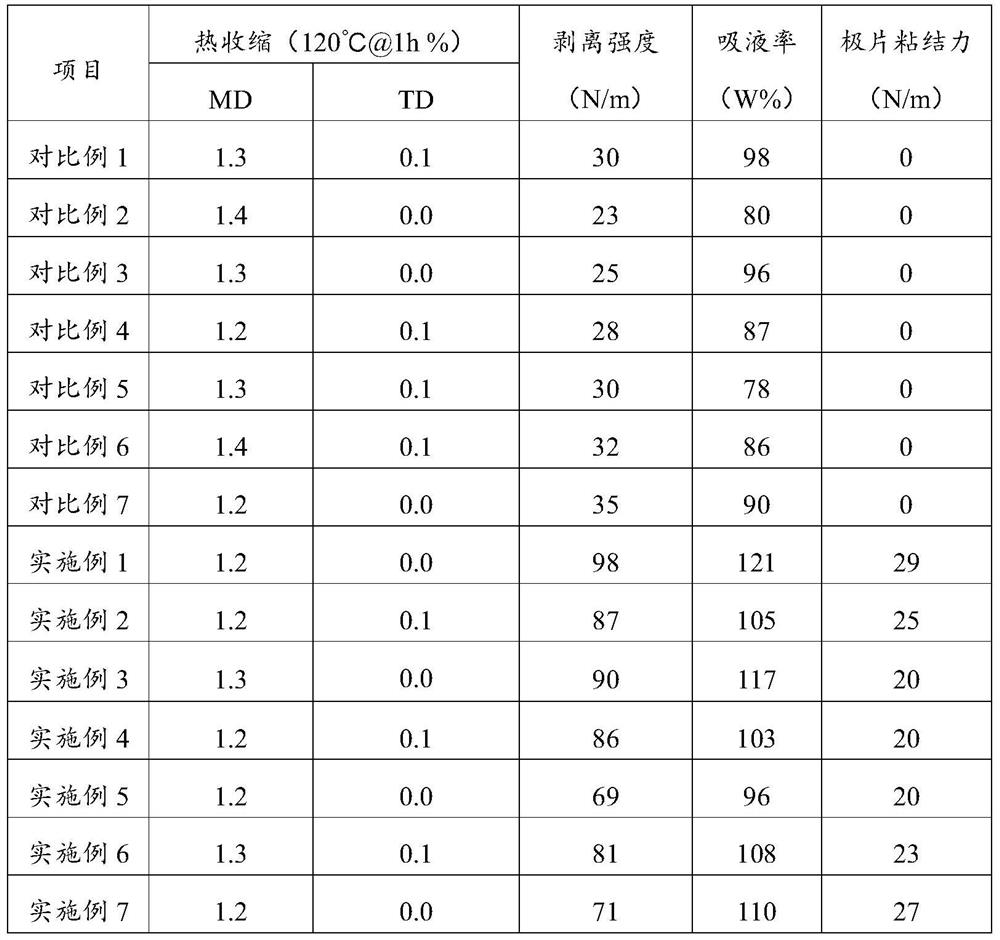

Examples

Embodiment 1

[0034] In this example, a polypropylene microporous membrane with a thickness of 16 μm, a porosity of 40%, and a pore diameter of 0.02-0.03 μm was used as the base membrane by Shenzhen Zhongxing Innovative Materials Technology Co., Ltd.; aluminum oxide grafted with polyethylene glycol on the surface was used to prepare The ceramic coating diaphragm of this example; wherein, Al2O3 is purchased from Sumitomo, Japan, and the particle size is D500.50-0.82 μm. The specific preparation method is as follows:

[0035] 1. Preparation of Surface Grafted Polyethylene Glycol Al2O3

[0036] Disperse aluminum oxide particles in ethanol, add aminosilane coupling agent, react at 60°C, pH value about 6.5, react for 3 hours, wash and dry the reaction product to obtain aluminum oxide with amino groups on the surface; Aluminum oxide with amino groups on the surface and polyethylene glycol with carboxyl groups at the end are mixed, stirred and reacted at 50° C. for 1 hour, and then washed with wa...

Embodiment 2-7

[0041] Examples 2-7 respectively prepared silicon dioxide, zirconium dioxide, titanium dioxide, zinc oxide, magnesium oxide and calcium carbonate grafted with polyethylene glycol on the surface, which were used to prepare ceramic coating separators. details as follows:

Embodiment 2

[0042] Example 2 is similar to Example 1, except that silicon dioxide is used instead of aluminum oxide to form silicon dioxide grafted with polyethylene glycol on the surface, which is used to prepare a ceramic coating separator. All the other conditions are the same as in Example 1. Among them, the particle size of silicon dioxide is D50 0.50-0.61 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com