High-compactness high-temperature porcelain phenolic resin permeable membrane suitable for RFI (Radio Frequency Interference) molding process and preparation method thereof

A technology of phenolic resin and molding process, which is applied in the field of high-density high-temperature porcelainable phenolic resin permeable membrane and its preparation, which can solve the problems of limited application, flame retardancy, high temperature resistance and poor ablation resistance, and achieve good melting performance. Permeability, high carbon residue rate, high viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Components: by weight: 50 parts of B80 phenolic resin, 30 parts of solvent-free liquid phenolic resin, 10 parts of bismaleimide modified phenolic resin, 10 parts of phenproxazine resin, forming 100 parts of RTM phenolic resin system . 200 parts of magnesium aluminum spinel particles, 150 parts of forsterite particles, and 100 parts of silicon carbide whiskers.

[0037] Step 1: After each component by weight part is weighed respectively, put into the oven of 70 ℃ and heat for 30 minutes. Use a mechanical stirring device to quickly mix the heated components. After stirring for about 5 to 10 minutes, the mixture becomes a homogeneous system. The uniformly mixed material is poured into a mold whose upper and lower templates are covered with release cloth, and the mold temperature is 80°C, and the film is calendered. After the calendering is completed, the film with the release cloth up and down is taken out together. After cooling to room temperature, the release cloth ca...

Embodiment 2

[0040] Components: by weight: 50 parts of B80 phenolic resin, 30 parts of solvent-free liquid phenolic resin, 10 parts of bismaleimide modified phenolic resin, 10 parts of phenproxazine resin, forming 100 parts of RTM phenolic resin system . 150 parts of magnesium aluminum spinel particles, 120 parts of forsterite particles, and 80 parts of silicon carbide whiskers.

[0041] Step 1: same as Step 1 in Example 1;

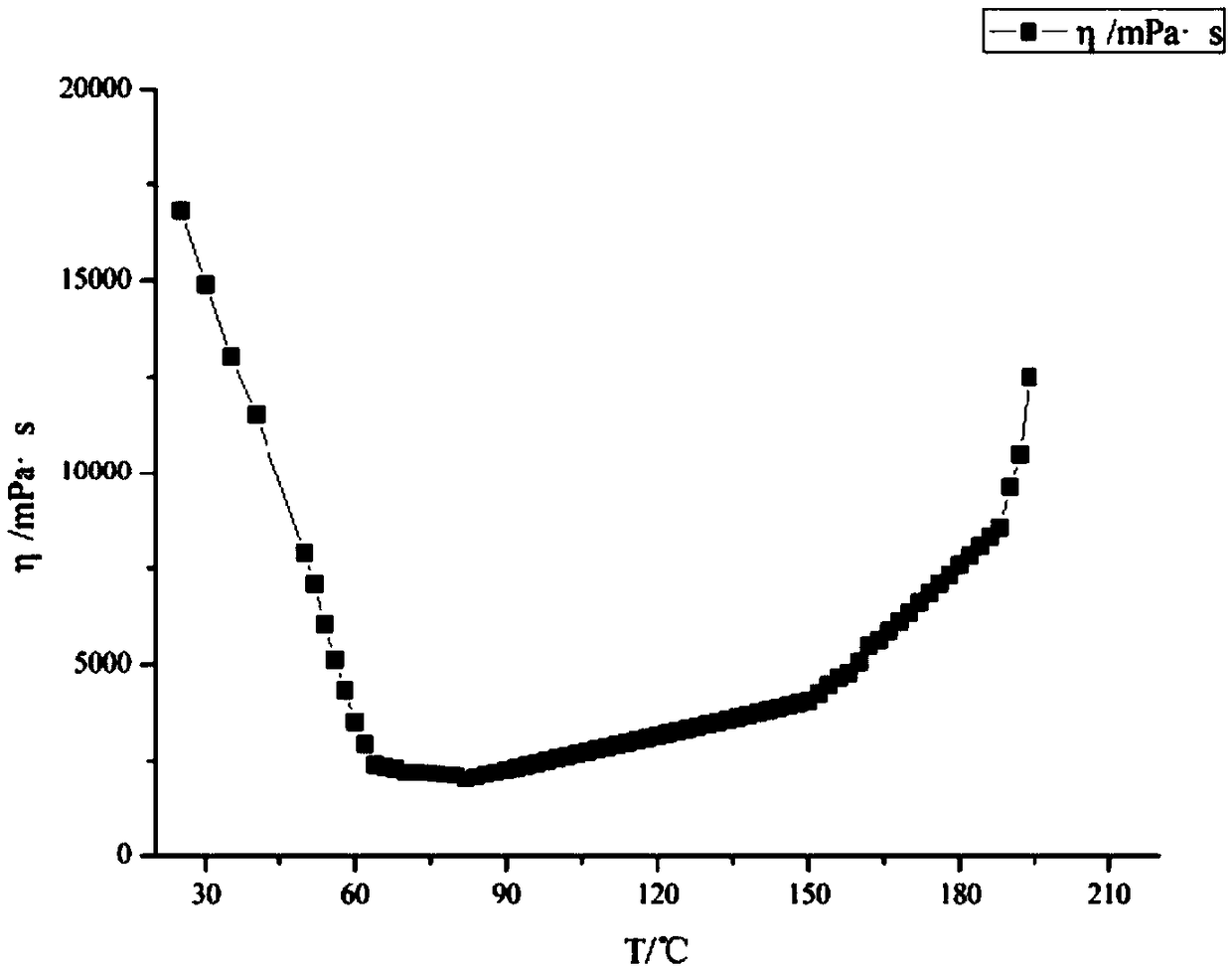

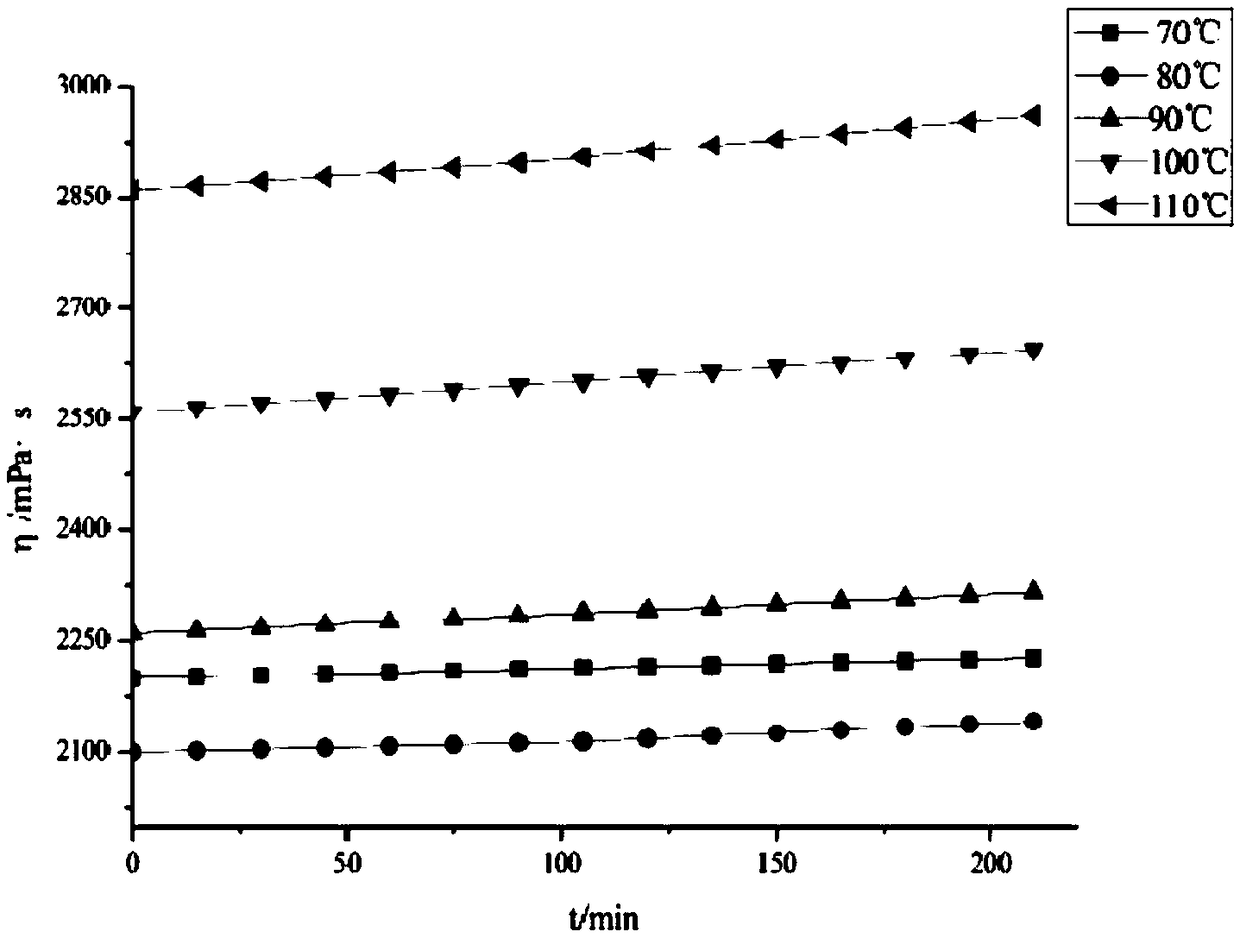

[0042] Step 2: Take a certain amount of permeable membrane, and use a flat plate rheometer to measure the viscosity-temperature curve and viscosity-time curve of the membrane, as shown in Figure 1. Figure 1(a) is the viscosity-temperature curve of the film. It can be seen from Figure 1(a) that with the increase of temperature, the viscosity of the film first decreases and then increases, and the viscosity is the lowest at 70°C to 80°C, and the viscosity-temperature curve is U-shaped. The U-shaped viscosity-temperature curve makes the film have good film-forming pro...

Embodiment 3

[0044] Components: by weight: 50 parts of B80 phenolic resin, 30 parts of solvent-free liquid phenolic resin, 10 parts of bismaleimide modified phenolic resin, 10 parts of phenproxazine resin, forming 100 parts of RTM phenolic resin system . 200 parts of magnesium aluminum spinel particles, 120 parts of forsterite particles, and 80 parts of silicon carbide whiskers.

[0045] Step 1: same as Step 1 in Example 1;

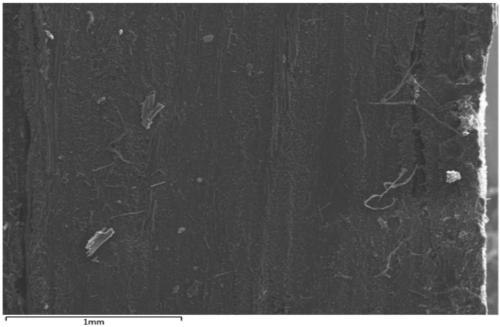

[0046] Step 2: Lay 40 pieces of carbon fiber plain weave cloth with a size of 100×100×0.28mm in the direction of 0° / 90°, take two prepared permeable membranes, and cover the permeable membrane on one side of the carbon fiber laminated fabric, Seal it with high temperature resistant sealant and a vacuum bag with a vacuum joint, put it in an autoclave, and use the RFI process to heat cure and form. The vacuum degree in the vacuum bag is 0.1MPa, the positive pressure of the autoclave is 0.2MPa, the temperature rise rate is 2°C / min, and the positive pressure increase ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com