Fast ageing process of T/C fabric dispersion/active camouflage prints

A printing and fabric technology, which is applied in the field of textile printing and dyeing processing, can solve the problems affecting steaming energy consumption, etc., and achieve the effects of reducing the difficulty of matching flowers, narrowing the color gap, and improving the stability of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] T / C 65 / 35 20×20 108×58 150cm Gauze jungle camouflage printed cloth

[0039] 1. Process flow

[0040] Singeing—deboiling and bleaching—mercerizing—setting—dyeing base color—printing—baking—rapid steaming—washing—finishing—finished product

[0041] 2. Process conditions

[0042] (1) The process conditions of the pre-treatment process are the same as those of the traditional printing process. The wool effect of the fabric is required to be 8-10cm / 30min, the whiteness consistency is good, the pH value of the cloth surface is 7-8 and uniform, and the cloth surface should be flat and the width is consistent after the shaping process. The ground color usually uses the dispersion / reduction process, which requires the color to be consistent, fully washed, and the cloth to be rolled. The pre-treatment requires the consistency of the indicators and the cloth surface is clean and free of fluff, so as to prevent uneven dyeing and blockage of the flower net to cause missing printi...

Embodiment 2

[0059] According to embodiment 1 process condition, adjust the pulping slurry formula as follows:

[0060] The composition of the slurry is that each liter of slurry contains:

[0061] Disperse dye 10g

[0062] Reactive dye 5g

[0063] Raw paste 750g

[0064] Urea 40g.

Embodiment 3

[0066] According to embodiment 1 process condition, adjust the pulping slurry formula as follows:

[0067] The composition of the slurry is that each liter of slurry contains:

[0068] Disperse dye 50g

[0069] Reactive dye 30g

[0070] Raw paste 750g

[0071] Urea 40g.

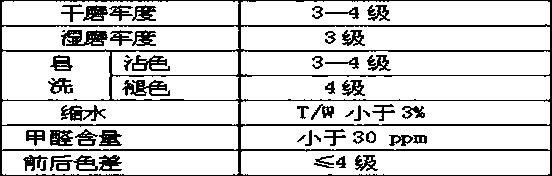

[0072] By the technique of embodiment 1-3, the main index detection of finished product all can be higher than following standard:

[0073]

[0074] Moreover, the steam consumption of the steamer during the processing is 250-300kg / hour, which greatly reduces the steam consumption.

[0075] In addition, the storage time of the remaining slurry can be extended to one week, and the finished products used in the rapid steaming process are not inferior to the traditional steaming process in terms of pattern fineness, color brightness, color yield, color fastness, and hand feeling. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com