A kind of formula of high pressure-resistant temperature stable dielectric material and its preparation method

A temperature-stable, dielectric material technology, used in fixed capacitor dielectrics, fixed capacitors, and components of fixed capacitors, etc., can solve problems such as increasing the volume of high-voltage energy storage capacitors, unfavorable industrial production of capacitor products, etc., to reduce loss, The effect of improving density and reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

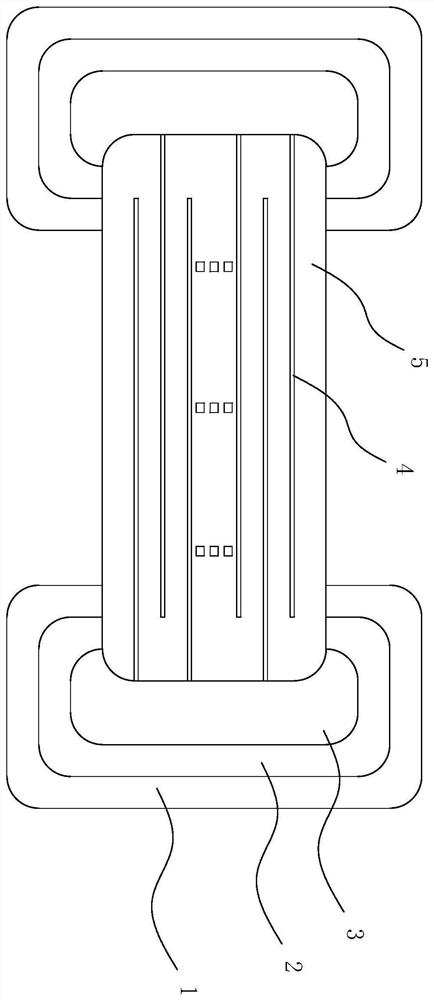

Image

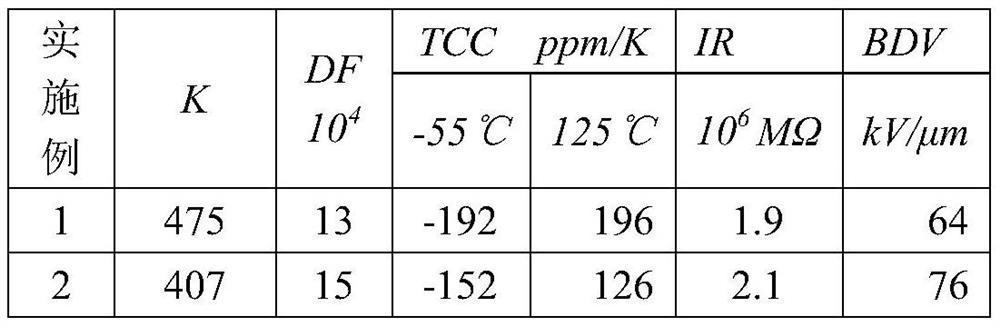

Examples

Embodiment 1

[0030] (1) According to the molar ratio of 1:1, weigh 23.44 parts by weight of ZnO and 76.56 parts by weight of Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 800°C for 4 hours to synthesize ZnNb 2 o 6 ;

[0031] (2) According to the molar ratio of 3:1:1, weigh 63.03 parts by weight of BaCO 3 , 8.66 parts by weight ZnO and 28.30 parts by weight Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1000°C for 4 hours to synthesize Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 ;

[0032] (3) According to the molar ratio of 4:4:1, weigh 51.43 parts by weight of ZnO, 39.08 parts by weight of H 3 BO 3 , 9.49 parts by weight SiO 2 , fully mixed, 40-mesh sieve, heated to 1350°C and kept for 0.5h, quenched to room temperature, and made into ZBS glass

[0033] (4) Take by weight, 100g BaTiO 3 , 7.44g ZnNb 2 o 6 , 17.30g Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 , 0.25gMnCO 3 , 0.33g Er 2 o 3 , 1.72g ZBS glass was used for batchi...

Embodiment 2

[0036] (1) According to the molar ratio of 1:1, weigh 23.44 parts by weight of ZnO and 76.56 parts by weight of Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 950°C for 1 hour to synthesize ZnNb 2 o 6 ;

[0037] (2) According to the molar ratio of 3:1:1, weigh 63.03 parts by weight of BaCO 3 , 8.66 parts by weight ZnO and 28.30 parts by weight Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1050°C for 3 hours to synthesize Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 ;

[0038](3) According to the molar ratio of 4:4:1, weigh 51.43 parts by weight of ZnO, 39.08 parts by weight of H 3 BO 3 , 9.49 parts by weight SiO 2 , fully mixed, 40-mesh screen, heated to 1400°C and kept for 0.5h, quenched to room temperature, and made into ZBS glass

[0039] (4) Take by weight, 100g BaTiO 3 , 6.21g ZnNb 2 o 6 , 19.37g Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 , 0.10gMnCO 3 , 0.13g La 2 o 3 , 2.92g ZBS glass for batching. Using...

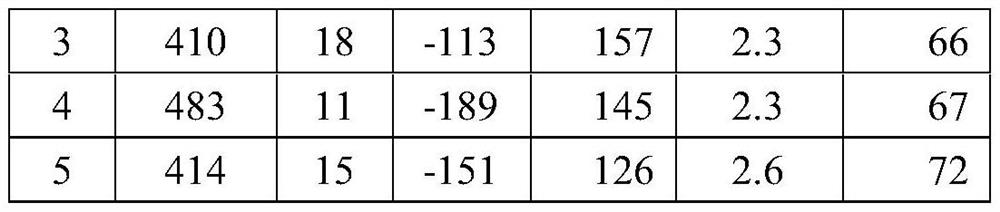

Embodiment 3

[0042] (1) According to the molar ratio of 1:1, weigh 23.44 parts by weight of ZnO and 76.56 parts by weight of Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 850°C for 3 hours to synthesize ZnNb 2 o 6 ;

[0043] (2) According to the molar ratio of 3:1:1, weigh 63.03 parts by weight of BaCO 3 , 8.66 parts by weight ZnO and 28.30 parts by weight Nb 2 o 5 , mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1100°C for 2 hours to synthesize Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 ;

[0044] (3) According to the molar ratio of 4:4:1, weigh 51.43 parts by weight of ZnO, 39.08 parts by weight of H 3 BO 3 , 9.49 parts by weight SiO 2 , fully mixed, 40-mesh sieve, heated to 1350°C and kept for 0.5h, quenched to room temperature, and made into ZBS glass

[0045] (4) Take by weight, 100g BaTiO 3 , 8.00g ZnNb 2 o 6 , 10.30g Ba(Zn 1 / 3 ,Nb 2 / 3 )O 3 , 0.10gMnCO 3 , 0.36g Gd 2 o 3 , 1.02g ZBS glass for batching. Usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com