Personalized pure tantalum false tooth inner crown laser additive manufacturing forming method

A laser additive and denture technology, which is applied in medical science, dentistry, dental prosthesis, etc., can solve problems such as high repair rate, reduced chewing efficiency, and difficulty in restoring balance and stability of dentures, so as to reduce shrinkage cavity deformation and repair, The effect of eliminating human error and improving human safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

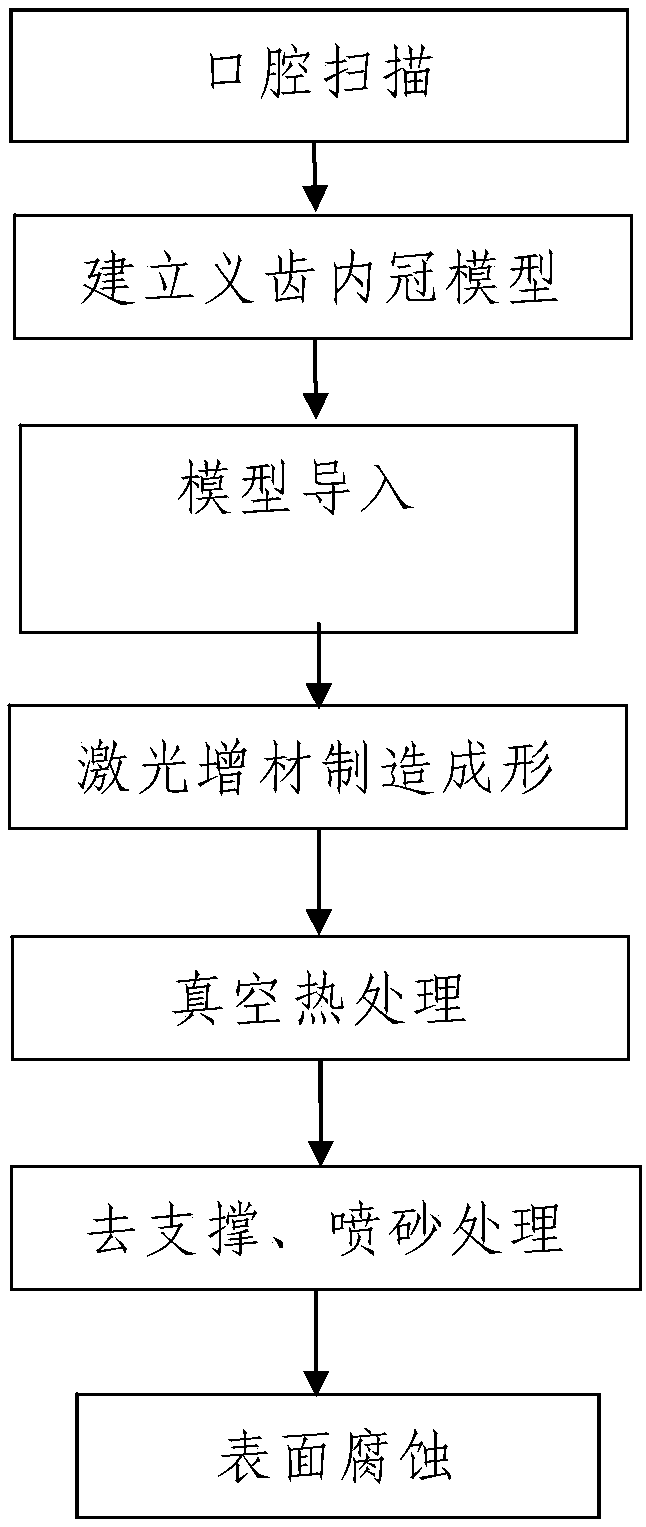

[0027] This embodiment includes the following steps:

[0028]Step 1. Use an oral scanner to scan the missing teeth in the oral cavity, obtain the oral scanning data results and import them into the dental special design software 3shape, and then construct the denture inner crown and obtain the STL format file;

[0029] Step 2, import the STL format file obtained in step 1 into Magics software, utilize the Magics software to establish the three-dimensional model of the inner crown of the denture and add support, then correct and optimize the three-dimensional model of the inner crown of the denture; the optimization includes: A square groove structure is designed on the outer surface of the three-dimensional model of the inner crown, the side length of the square groove structure is 100 μm, and the height is 100 μm;

[0030] Step 3. Import the optimized three-dimensional model in step 2 into the laser additive manufacturing equipment, and use laser additive molding method to ma...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. Use an oral scanner to scan the missing teeth in the oral cavity, obtain the oral scanning data results and import them into the dental special design software 3shape, and then construct the denture inner crown and obtain the STL format file;

[0037] Step 2, import the STL format file obtained in step 1 into Magics software, utilize the Magics software to establish the three-dimensional model of the inner crown of the denture and add support, then correct and optimize the three-dimensional model of the inner crown of the denture; the optimization includes: A square groove structure is designed on the outer surface of the three-dimensional model of the inner crown, the side length of the square groove structure is 400 μm, and the height is 200 μm;

[0038] Step 3. Import the optimized three-dimensional model in step 2 into the laser additive manufacturing equipment, and use laser additive molding method to m...

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] Step 1. Use an oral scanner to scan the missing teeth in the oral cavity, obtain the oral scanning data results and import them into the dental special design software 3shape, and then construct the denture inner crown and obtain the STL format file;

[0045] Step 2, import the STL format file obtained in step 1 into Magics software, utilize the Magics software to establish the three-dimensional model of the inner crown of the denture and add support, then correct and optimize the three-dimensional model of the inner crown of the denture; the optimization includes: A square groove structure is designed on the outer surface of the three-dimensional model of the inner crown, the side length of the square groove structure is 200 μm, and the height is 150 μm;

[0046] Step 3. Import the optimized three-dimensional model in step 2 into the laser additive manufacturing equipment, and use laser additive molding method to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com