Preparation method of titanium-based tantalum coating biological implant material

A technology for tantalum coatings and implants, which is applied in the field of preparation of tantalum metal coatings, can solve the problems of unsteady control of deposition rate, insufficient bonding force between coatings and substrates, and large residual thermal stress of coatings, etc., to achieve optimal clinical Application effect, tantalum coating uniformity, effect of improving biological characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

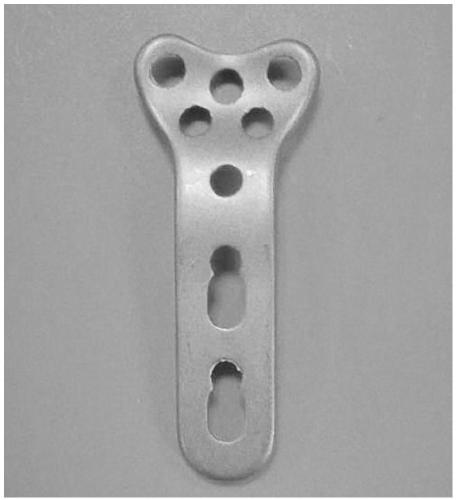

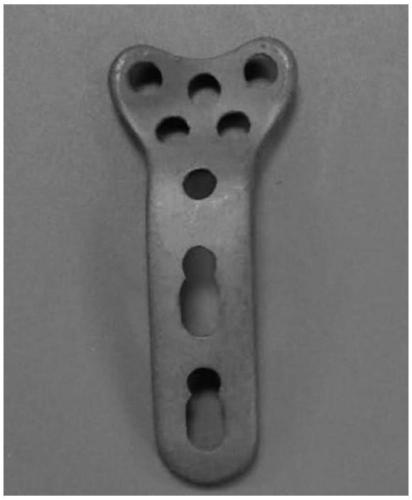

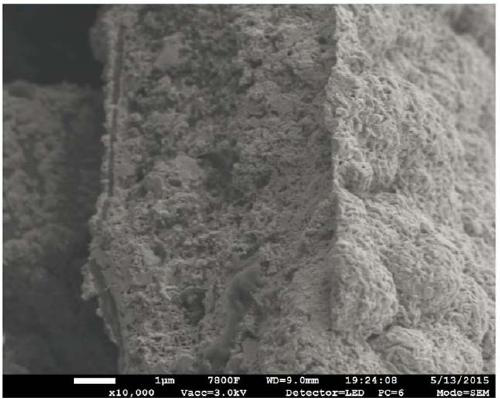

[0033] A titanium-based tantalum-coated biological implant is prepared by depositing tantalum metal on the surface of a titanium alloy bone plate matrix by using chemical vapor deposition technology. The preparation method is as follows:

[0034] (1) Preprocessing:

[0035] The titanium alloy bone plate matrix was ultrasonically treated with deionized water for 30 minutes, then dried, washed twice with absolute ethanol, dried, and finally dried at 150 °C;

[0036] The dried titanium alloy bone plate matrix is subjected to sandblasting treatment with a sandblasting machine to form a rough surface.

[0037] The steps of sand blasting treatment are as follows: use white jade corundum with a diameter of 100-150 μm for sand blasting, the sand blasting pressure is 0.3 MPa, and the sand blasting time is 5 minutes. After sandblasting, clean with absolute alcohol, blow dry with nitrogen, and set aside;

[0038] (2) Put the pretreated titanium alloy bone plate substrate into the vap...

Embodiment 2~ Embodiment 5

[0047] The titanium-based tantalum-coated biological implant was prepared according to the method described in Example 1, and the differences between the preparation method and Example 1 are shown in Table 1.

[0048] Table 1 Process conditions for preparing tantalum metal-coated titanium alloy bone plate

[0049]

[0050] For the tantalum-coated titanium alloy bone plate prepared under different process conditions as described in Table 1, the mechanical properties and the bonding force between the tantalum coating and the substrate were measured, and the results are shown in Table 2.

[0051] Properties of the tantalum-coated titanium alloy bone plate prepared under the process conditions described in Table 2 Table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com