High-temperature fused salt battery

A high-temperature molten salt and battery technology, applied in the field of molten salt, can solve the problems of corrosion, leakage, processing cost, fragility, etc., and achieve the effects of avoiding battery short circuit or open circuit, reducing fluidity, improving cycle charge and discharge, and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

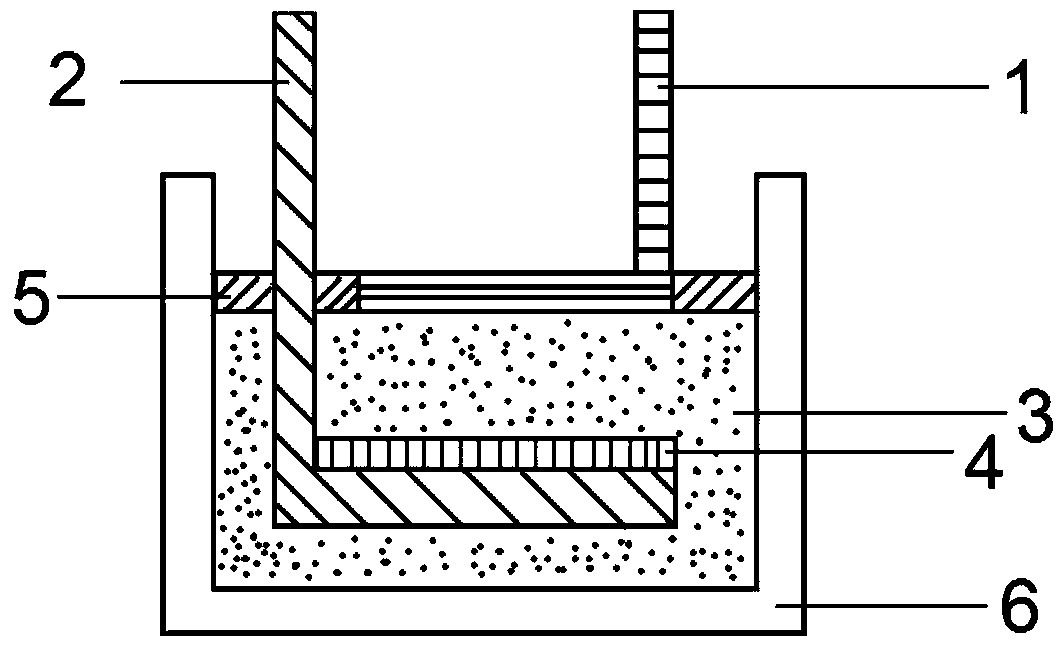

[0027] Such as figure 1 Reference numeral 1 in the structural schematic diagram of the high-temperature molten salt battery shown is silver positive electrode; 2 is silver negative electrode; 3 is paste double electrolyte formed by mixing potassium carbonate and zirconia micron powder containing yttrium oxide; 4 is iron ; 5 is a high temperature sealant; 6 is a corundum tube.

[0028] Iron is deposited on the surface of the silver negative electrode by chemical deposition, and then placed in a corundum tube; at 950 ° C, potassium carbonate and solid electrolyte powder (zirconia micron powder containing yttrium oxide, that is, yttrium oxide doped in oxide The paste double electrolyte formed by mixing the yttrium oxide stabilized zirconia formed in zirconium) is added therein, wherein the content of potassium carbonate is 60%, and the mole percentage content of yttrium oxide in the solid electrolyte powder is 8mol%, and the The particle size is 2 microns; the silver positive el...

Embodiment 2

[0031] Such as figure 1 In the schematic diagram of the structure of the high-temperature molten salt battery shown, reference numeral 1 is a platinum positive electrode; 2 is a silver negative electrode; 3 is a paste double electrolyte formed by mixing potassium carbonate and zirconia micron powder containing yttrium oxide; 4 is copper ; 5 is a high temperature sealant; 6 is a corundum tube.

[0032] Copper is deposited on the surface of the silver negative electrode by chemical deposition, and then put into the corundum tube; at 950 ° C, the paste double electrolyte formed by mixing potassium carbonate and zirconia micron powder containing yttrium oxide is added to it, of which potassium carbonate The content of yttrium oxide in the solid electrolyte powder is 40%, the content of yttrium oxide in the solid electrolyte powder is 5mol%, and the particle size of the powder is 20 microns; the silver positive electrode is placed on the surface of the paste electrolyte, after cool...

Embodiment 3

[0035] Such as figure 1 In the schematic diagram of the structure of the high-temperature molten salt battery shown, reference numeral 1 is a silver positive electrode; 2 is a silver negative electrode; 3 is a paste double electrolyte formed by mixing sodium carbonate and zirconia micron powder containing yttrium oxide; 4 is zinc ; 5 high temperature sealant; 6 is corundum tube.

[0036] Zinc is deposited on the surface of the silver negative electrode by chemical deposition, and then placed in a corundum tube; at 900 ° C, the paste double electrolyte formed by mixing potassium carbonate and zirconia micron powder containing yttrium oxide is added to it, of which sodium carbonate The content of yttrium oxide in the solid electrolyte powder is 50%, the content of yttrium oxide in the solid electrolyte powder is 8mol%, and the particle size of the powder is 0.1 micron; The silver positive electrode is placed on the surface of the paste electrolyte, after cooling to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com