A photosensitive sensor based on an organic field effect tube and its preparation method

A photosensitive sensor and organic field technology, applied in the sensor field, can solve the problems of poor stability and low responsivity of the photosensitive sensor, and achieve the effects of rich content, high responsivity and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

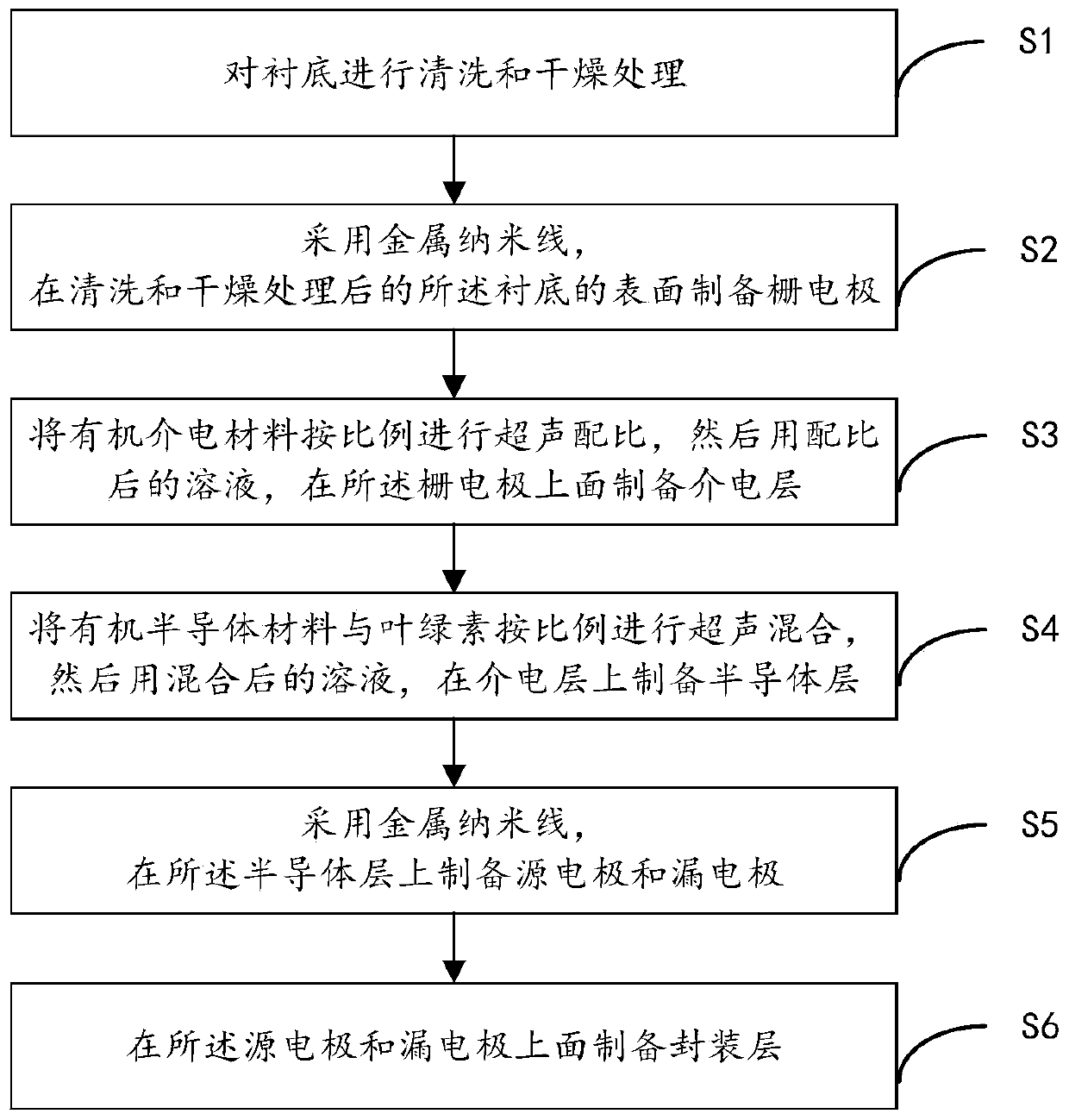

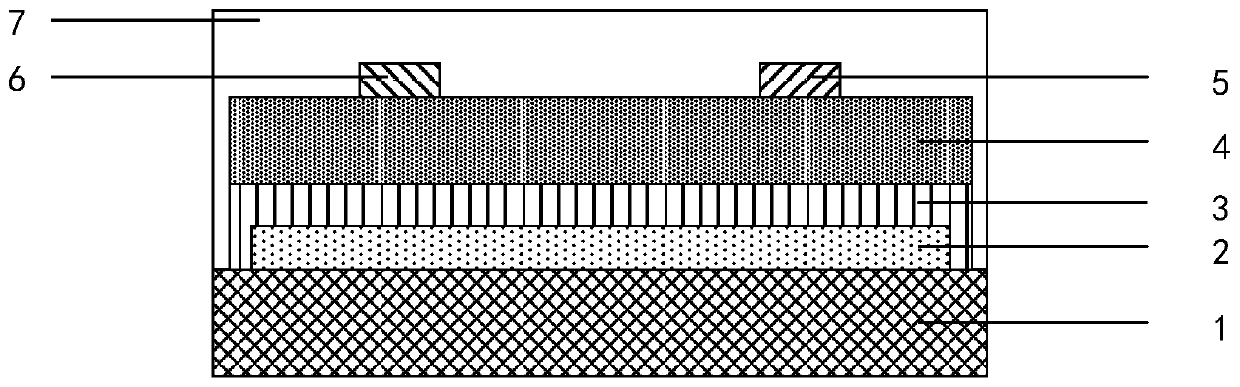

[0041] A method for preparing a photosensitive sensor based on an organic field effect transistor, such as figure 1 shown, including the following steps:

[0042] S1, cleaning and drying the substrate 1;

[0043] S2. Using metal nanowires, prepare a gate electrode 2 on the surface of the substrate 1 after cleaning and drying;

[0044] S3, ultrasonically proportioning the organic dielectric material in proportion, and then using the proportioned solution to prepare a dielectric layer 3 on the gate electrode 2;

[0045] S4, ultrasonically mixing the organic semiconductor material and chlorophyll in proportion, and then using the mixed solution to prepare a semiconductor layer 4 on the dielectric layer 3;

[0046] S5. Prepare a source electrode 5 and a drain electrode 6 on the semiconductor layer 4 by using metal nanowires;

[0047] S6 , preparing an encapsulation layer 7 on the source electrode 5 and the drain electrode 6 .

[0048] Further, the dielectric layer 3 in step S3 a...

Embodiment 1

[0059] A method for preparing a photosensitive sensor based on an organic field effect tube provided in this embodiment includes:

[0060] Step 1. Clean the substrate 1 with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0061] Step 2, using silver nanowires, through a method in vacuum thermal evaporation, magnetron sputtering, plasma enhanced chemical vapor deposition, screen printing, printing or spin coating, after cleaning and drying, the preparing a gate electrode 2 on the surface of the substrate 1;

[0062] Step 3. Ultrasonic proportioning of polystyrene (PS) according to a certain concentration, and then using the proportioned solution, through one of the methods of spin coating, roller coating, drop film, embossing, printing or spraying, in the place A dielectric layer 3 with a thickness of 500 nm is prepared on the gate electrode 2;

[0063] Step 4, ultrasonically mix 3-hexylthiophene (P3HT) and chl...

Embodiment 2

[0067] A method for preparing a photosensitive sensor based on an organic field effect tube provided in this embodiment includes:

[0068] Step 1. Clean the substrate 1 with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0069] Step 2, using gold nanowires, through a method in vacuum thermal evaporation, magnetron sputtering, plasma enhanced chemical vapor deposition, screen printing, printing or spin coating, after cleaning and drying, the preparing a gate electrode 2 on the surface of the substrate 1;

[0070] Step 3, ultrasonically proportioning polymethyl methacrylate according to a certain concentration, and then using the proportioned solution, through one of the methods of spin coating, roller coating, drop film, embossing, printing or spraying, in the place A dielectric layer 3 with a thickness of 300 nm is prepared on the gate electrode 2;

[0071] Step 4. Ultrasonic mixing Tips-pentacene (Tips-penta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com