Plastic material for beverage bottle

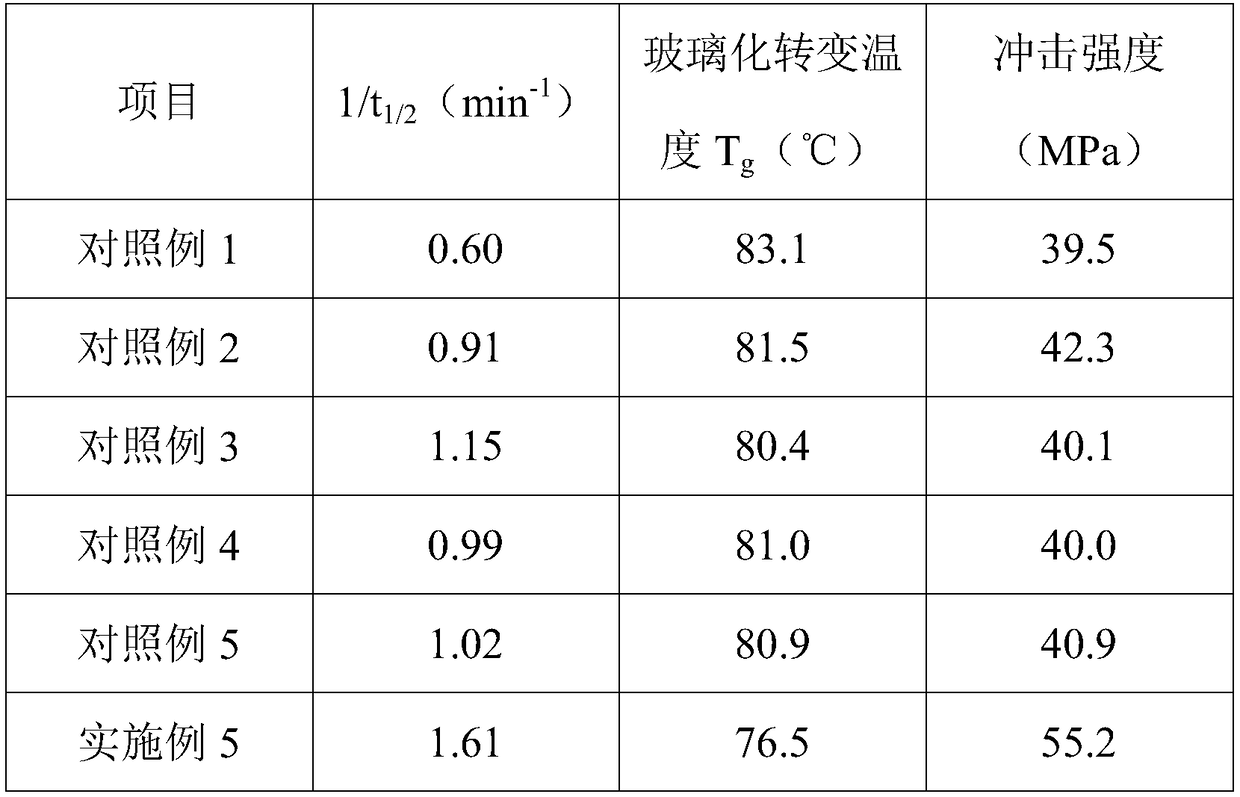

A technology for plastic materials and beverage bottles, which is applied in the field of plastic materials for beverage bottles, and can solve the problems of slow crystallization rate of polyethylene terephthalate, restrictions on the use of polyethylene terephthalate, and difficulties in molding and processing, etc. problems, achieve the effects of shortening the production and processing cycle, shortening the crystallization time, increasing mechanical properties and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of plastic material for beverage bottle, its raw material comprises by weight: 100 parts of polyethylene terephthalate, 30 parts of filler, 0.2 part of antioxidant, 2 parts of compatibilizer, 3 parts of nucleating agent, 2 parts of plasticizer, 3 parts of lubricant;

[0020] Wherein, the nucleating agent is sodium-based montmorillonite, nano-magnesium oxide, sodium chloride, and polyethylene oxide.

Embodiment 2

[0022] A kind of plastic material for beverage bottle, its raw material comprises by weight: 80 parts of polyethylene terephthalates, 35 parts of fillers, 0.1 part of antioxidant BHT, 3 parts of maleic anhydride graft compatibilizers, the composition 2 parts of nucleating agent, 3 parts of plasticizer, 2 parts of lubricant;

[0023] Among them, the nucleating agent is sodium-based montmorillonite, nano-magnesium oxide, sodium chloride, and polyethylene oxide, wherein the weight ratio of sodium-based montmorillonite, nano-magnesium oxide, sodium chloride, and polyethylene oxide is 5:1 :1:1;

[0024] The filler is light calcium carbonate, talcum powder and polytetrafluoroethylene superfine powder, wherein the weight ratio of light calcium carbonate, talc powder and polytetrafluoroethylene superfine powder is 12:10:3.

Embodiment 3

[0026] A kind of plastic material for beverage bottle, its raw material comprises by weight: 120 parts of polyethylene terephthalates, 25 parts of fillers, 0.3 part of antioxidant BHT, 1 part of maleic anhydride graft compatibilizer, the composition 4 parts of nucleating agent, 1 part of plasticizer, 4 parts of lubricant;

[0027] Among them, the nucleating agent is sodium-based montmorillonite, nano-magnesia, sodium chloride, and polyethylene oxide, wherein the weight ratio of sodium-based montmorillonite, nano-magnesium oxide, sodium chloride, and polyethylene oxide is 3:2 :0.5:2;

[0028] The filler is light calcium carbonate, talcum powder, and polytetrafluoroethylene ultrafine powder, wherein the weight ratio of light calcium carbonate, talc powder, and polytetrafluoroethylene ultrafine powder is 10:15:1;

[0029] The lubricant is white oil and natural paraffin, wherein the weight ratio of white oil and natural paraffin is 1:1;

[0030] The plasticizer is tributyl citra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com