A method for preparing superhydrophobic copper mesh by dipping and coating polymer nanoparticles

A nanoparticle, micro-nanoparticle technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of complex preparation process, limited in-situ growth method, long growth time, etc., and achieve simple and good preparation methods. Business prospects, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

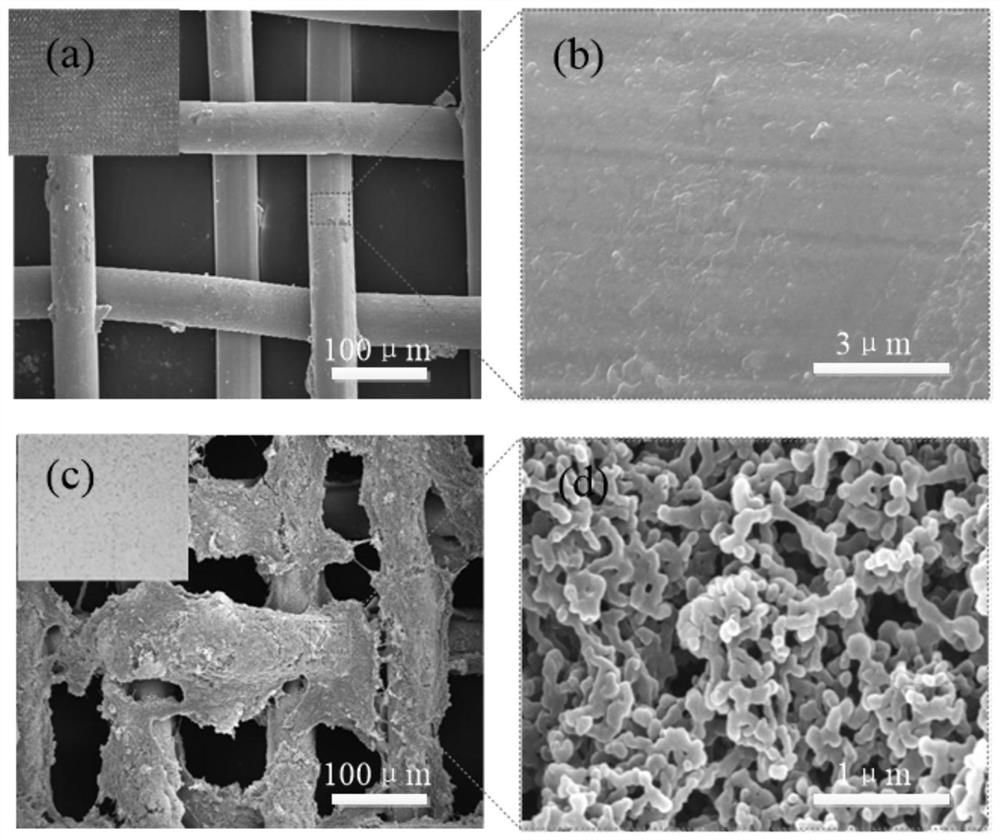

[0033] Superphobic polymer micro-nanoparticles were prepared by self-emulsification / solvent diffusion method.

[0034] (1) Dissolve 1g of thermoplastic polyurethane elastomer in 30ml of DMF to form solution A, add 15ml of n-butanol, and stir to form translucent solution B; pour the above solution into water, stir to form a milky white dispersion system, centrifuge, wash and press 1g The concentration of / L is dispersed in ethanol solution to obtain superhydrophobic dispersion of polymer;

[0035] (2) Dissolving industrial-grade quick-drying adhesive 502 (α-ethyl cyanoacrylate) in acetone to form a solution C with a concentration of 10 wt%, which is used as an adhesive for subsequent use;

[0036] (3) Place the copper grid to be processed in clear water and ethanol for ultrasonic cleaning for 30 minutes to remove surface impurities;

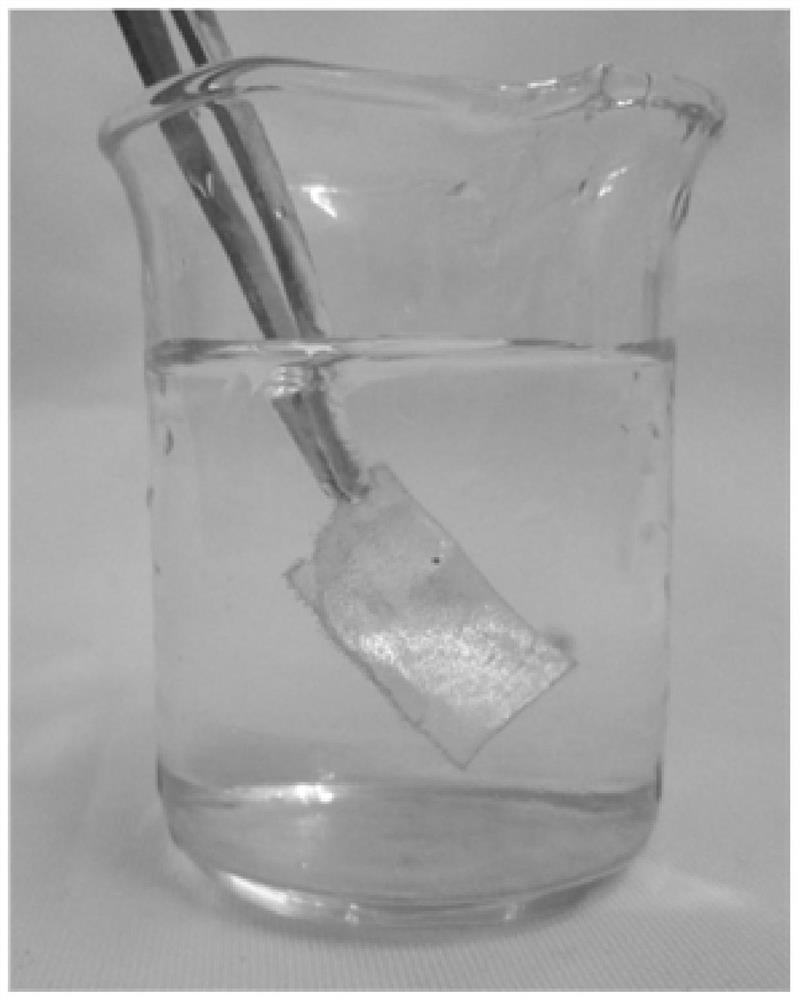

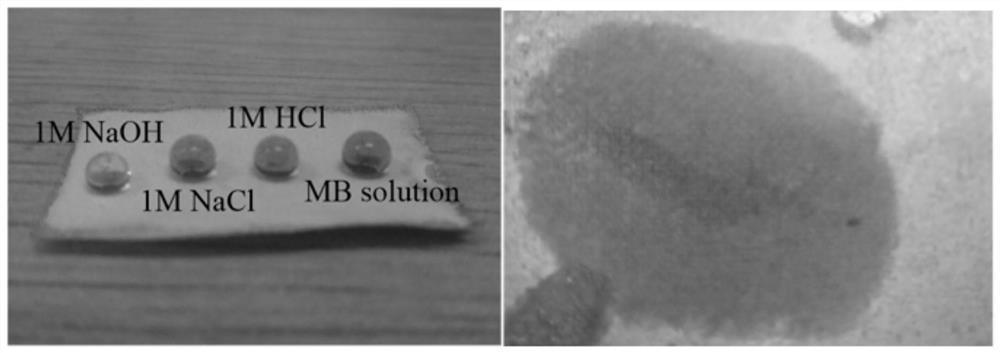

[0037] (4) Soak the cleaned copper mesh in solution C, take it out after 2 minutes, then soak it in the polymer superhydrophobic coating, take i...

Embodiment 2

[0040] (1) Prepare superphobic polymer micro-nanoparticles by self-emulsification / solvent diffusion method. Dissolve 1g PVDF in 30ml DMF to form solution A, add 10ml ethanol, stir to form translucent solution B; pour the above solution into water, stir to form a milky white dispersion system, centrifuge and wash, and disperse in ethanol solution at a concentration of 1g / L Obtain superhydrophobic polymer coating;

[0041] (2) Dissolving industrial-grade quick-drying adhesive 502 (α-ethyl cyanoacrylate) in acetone to form a solution C with a concentration of 15 wt%, which is used as an adhesive for subsequent use;

[0042] (3) Place the copper grid to be processed in clear water and ethanol for ultrasonic cleaning for 30 minutes to remove surface impurities;

[0043] (4) Soak the cleaned copper mesh in solution C, take it out after 2 minutes, then soak it in the polymer superhydrophobic coating, take it out after 2 minutes, and dry the surface of the copper mesh at 60°C. A sup...

Embodiment 3

[0046] (1) Prepare superphobic polymer micro-nanoparticles by self-emulsification / solvent diffusion method. Dissolve 1g PSF in 30ml DMF to form solution A, add 5ml ethanol, stir to form translucent solution B; pour the above solution into water, stir to form a milky white dispersion system, centrifuge, wash and disperse in ethanol solution at a concentration of 1g / L Obtain super-hydrophobic coatings;

[0047] (2) Dissolving industrial-grade quick-drying adhesive 502 (α-ethyl cyanoacrylate) in acetone to form a solution B with a concentration of 15 wt%, which is used as an adhesive for subsequent use;

[0048] (3) Place the copper grid to be processed in clear water and ethanol for ultrasonic cleaning for 30 minutes to remove surface impurities;

[0049] (4) Soak the cleaned copper mesh in solution C, take it out after 2 minutes, then soak it in the polymer superhydrophobic coating, take it out after 2 minutes, and dry the surface of the copper mesh at 60°C. A superhydrophobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com