writing board

A writing board and writing film technology, applied in the field of writing boards, can solve the problems of affecting the overall performance of light-cured materials, affecting the polymerization reaction, large volume shrinkage affecting adhesion, etc., achieving fast curing rate, reducing viscosity and surface tension, printing high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

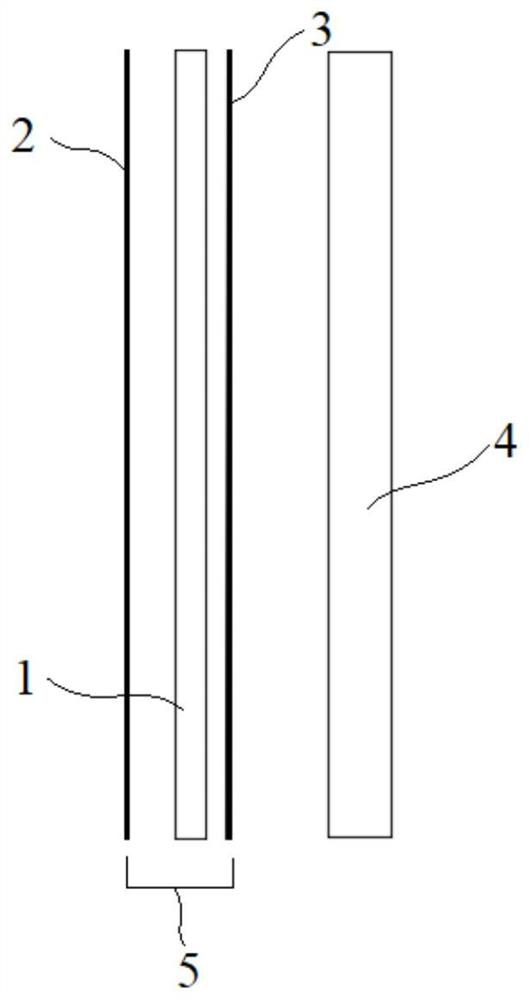

[0039] Embodiments 1 to 4: a writing board, including a support board 4 and a writing film 5, the writing film 5 is attached to the surface of one side of the support board 4;

[0040] The writing film 5 further includes a base material 1 and a matte coating layer 2 coated on one surface of the base material 1, and the other surface of the base material 1 and the support plate 4 are bonded and connected by an adhesive layer 3 ;

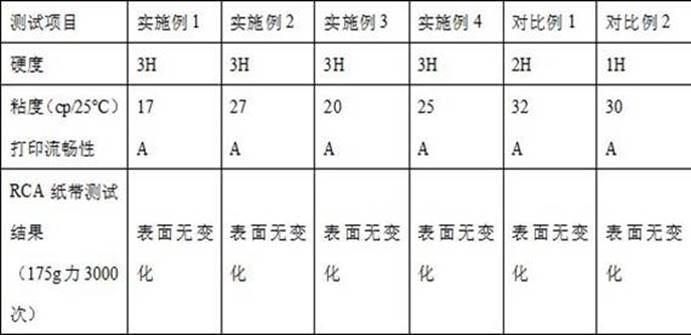

[0041] The matt coating layer 2 is obtained by the coating material under ultraviolet light irradiation, and the coating material is composed of the following components by weight, as shown in Table 1:

[0042] Table 1

[0043] components Example 1 Example 2 Example 3 Example 4 Aliphatic polyurethane triacrylate 20 copies 24 copies 18 copies 27 copies 1,6 hexanediol diacrylate 40 copies 48 copies 36 copies 35 copies Ethylene glycol diglycidyl ether 11 copies 13 copies 12 copies 12 copies A...

Embodiment 1

[0050] Embodiment 1: the above substrate 1 is a polymethyl methacrylate (PMMA) layer; the above adhesive layer 3 is an acrylic polyester adhesive layer; the above support plate 4 is a glass layer.

Embodiment 2

[0051] Embodiment 2: the above-mentioned substrate 1 is a polycarbonate (PC) layer; the above-mentioned adhesive layer 3 is a silicone-based adhesive layer; the above-mentioned support plate 4 is a metal plate layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com