Method for preparing nanometer MAX phase ceramic powder with laminated structure or slurry through ball milling and regulating oxygen content of powder

A technology of ceramic powder and lamellar structure, which is applied in the field of ceramic materials to achieve the effects of enhancing portability, meeting material requirements, and achieving effectiveness and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this example, the method of ball milling to prepare nano MAX phase ceramic powder or slurry with lamellar structure and control the oxygen content of the powder is as follows:

[0043] (1) Weigh the product name Ti 3 AlC 2 50 grams of MAX phase ceramic powder, the ceramic powder laser particle size analyzer measured particle size median diameter of 100 microns, weighed 0.2 grams of dispersant sodium polymethacrylate.

[0044] (2) Put Ti 3 AlC 2 Ceramic powder and dispersant are packed into a stainless steel ball mill jar with a volume of 500mL that can be fed into the gas, and 400 grams of stainless steel balls are put into it.

[0045] (3) Install the ball mill jar on a planetary ball mill that can continuously feed gas, start to feed a mixed gas with a volume ratio of hydrogen and argon of 1:5, and the gas flow rate is 5 liters / hour, and keep the gas flowing until the ball mill jar The temperature drops to the set point.

[0046] (4) Set the ambient temperatur...

Embodiment 2

[0051] In this example, the method of ball milling to prepare nano MAX phase ceramic powder or slurry with lamellar structure and control the oxygen content of the powder is as follows:

[0052] (1) Weigh the product name as Nb 3 AlC 2 500 grams of MAX phase ceramic powder, the ceramic powder laser particle size analyzer has a particle size of 50 microns in diameter, and liquid argon is used as a medium for ball milling.

[0053] (2) Nb 3 AlC 2 Ceramic powder, put into a polyurethane ball mill tank with a volume of 10L that can pass through gas or liquid, and put 8 kg of polyurethane-coated iron balls.

[0054] (3) Install the ball mill jar on the roller ball mill, start to feed liquid argon and liquid hydrogen into the ball mill jar, the flow rate of liquid argon is 2 liters / hour, and the flow rate of liquid hydrogen is 0.5 liters / hour.

[0055] (4) Maintain the feeding of the liquid gas until the temperature in the ball mill tank is kept constant at -150° C., start the b...

Embodiment 3

[0060] In this example, the method of ball milling to prepare nano MAX phase ceramic powder or slurry with lamellar structure and control the oxygen content of the powder is as follows:

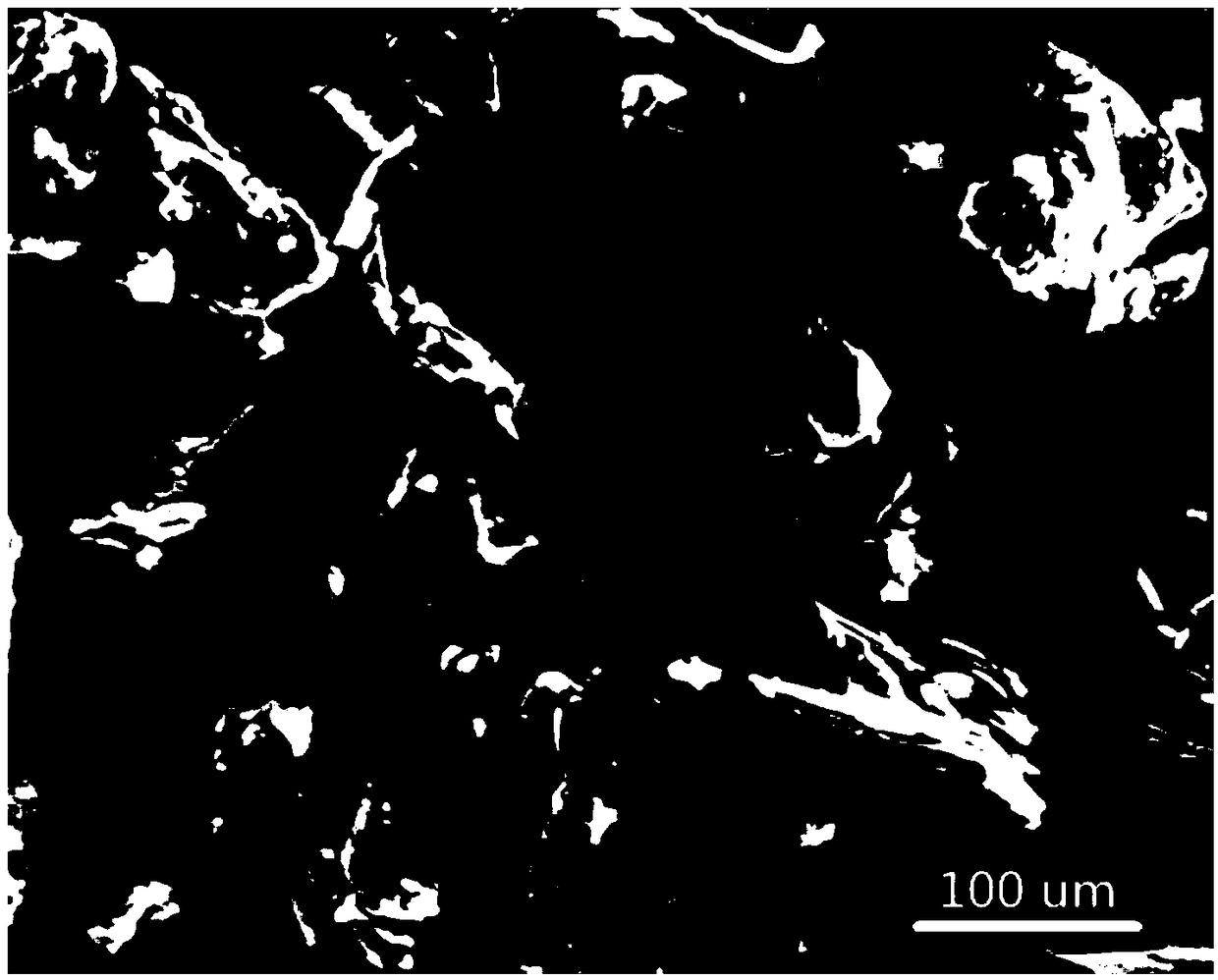

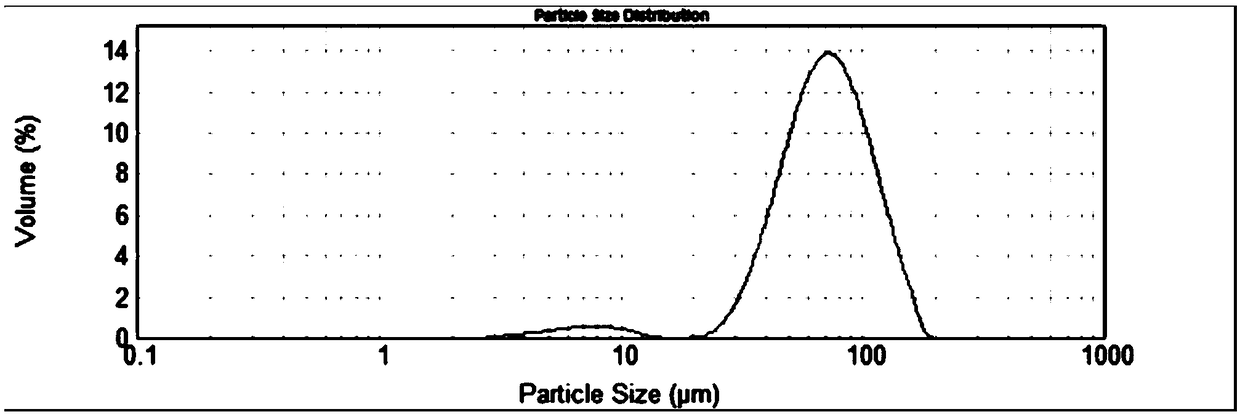

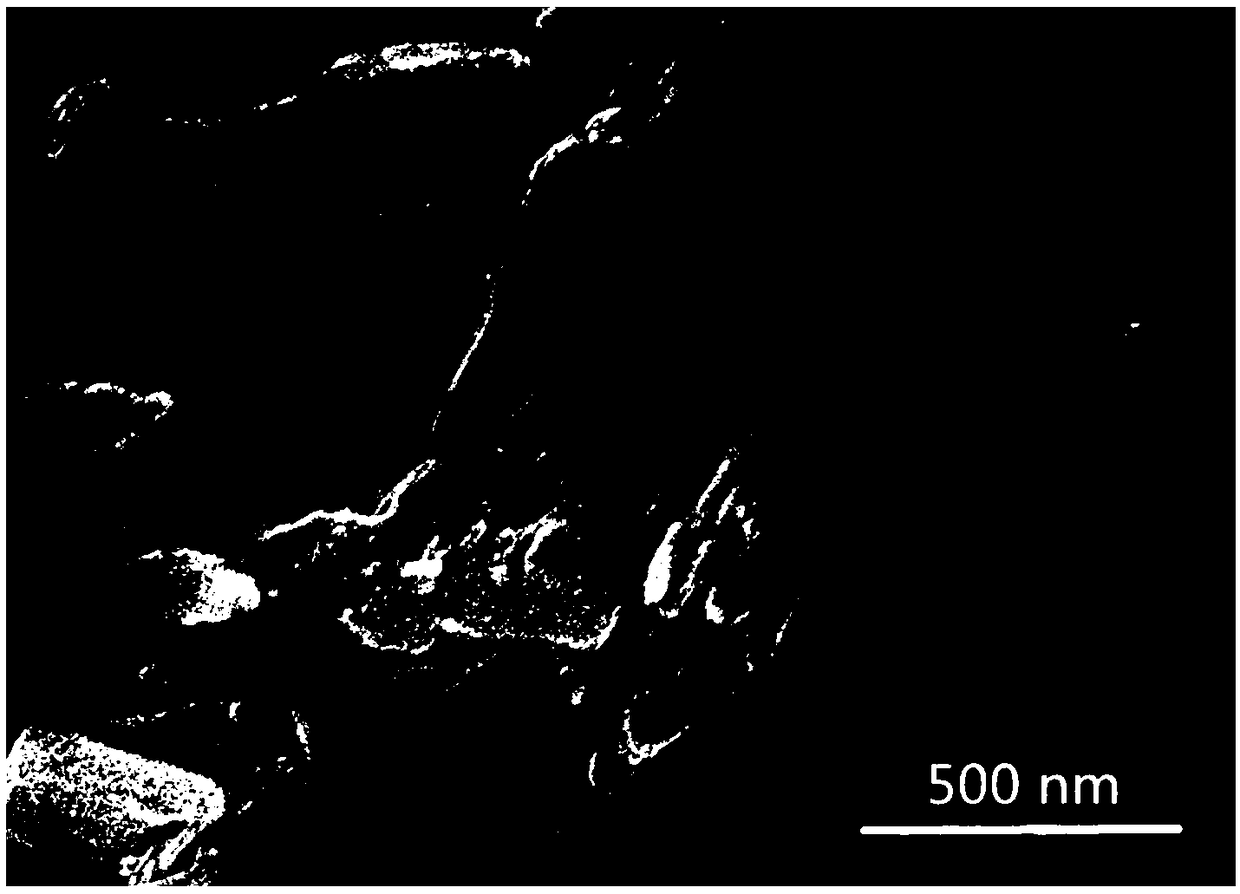

[0061] (1) Weigh the product name Ti 2 AlC MAX phase ceramic powder 500g, powder scanning electron microscope photo see figure 1 . The ceramic powder laser particle size analyzer measures the median diameter of the particle size to be 80 microns (see the results of the particle size measurement data) figure 2 ), measure 1000 milliliters of liquid toluene.

[0062] (2) Put Ti 2 AlC ceramic powder, deionized water packing volume is that 5L can pass into the vacuum agate mill mixing tank of gas, puts into 4 kilograms of agate balls.

[0063] (3) Install the ball mill tank on a stirring ball mill with a temperature-controlled medium jacket and temperature control, start to feed a mixed gas with a volume ratio of oxygen and nitrogen of 1:4, and the gas flow rate is 10 liters / hour, and keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com