Compound fermented feed additive for egg-laying poultry as well as preparation method and application of additive

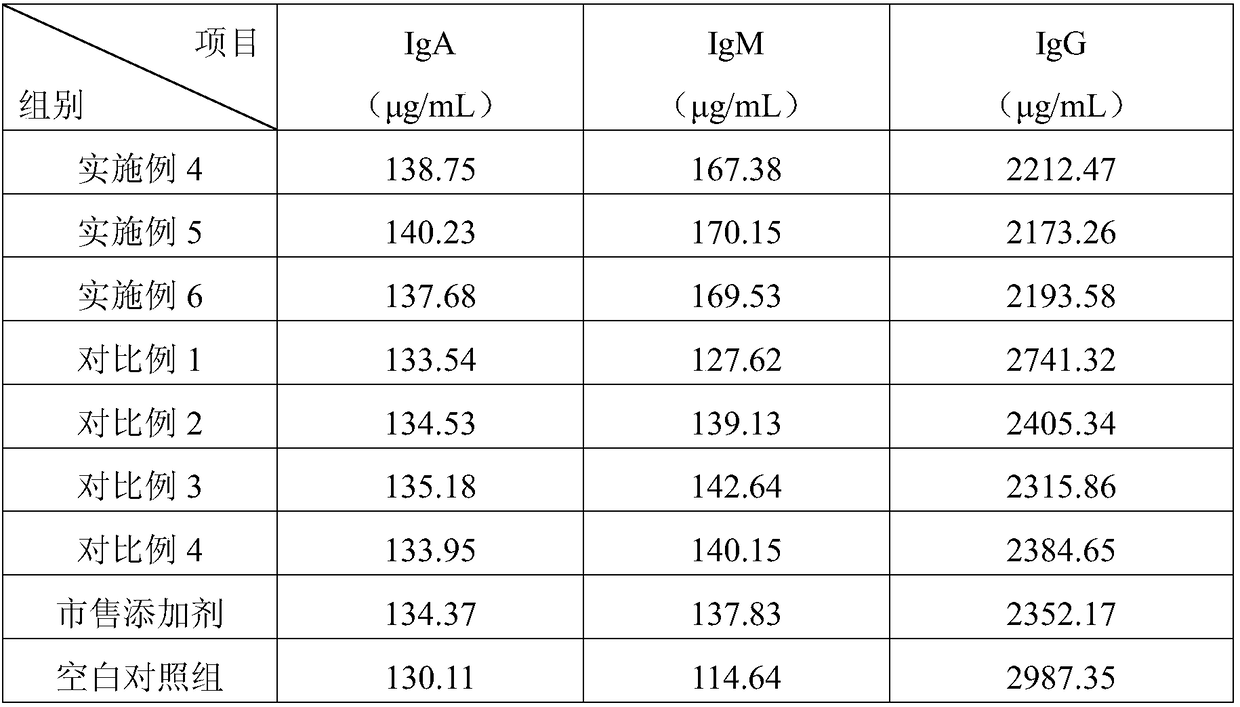

A feed additive, compound fermentation technology, applied in the direction of bacteria, application, animal feed, etc. used in food preparation, can solve the problems such as failure to achieve the desired effect, irregular egg laying time, reduced utilization rate, etc., to improve the immunity of the body , The effect of improving egg production quality and enriching nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of fermented algae powder, the steps are as follows:

[0041] (1) Dry and pulverize macroalgae, pass through a 40-mesh sieve, sterilize by high-pressure steam at 121°C for 15 minutes, cool to room temperature, and set aside;

[0042] (2) Centrifuge the culture fluid of Chlorella and Chrysophylla respectively to obtain the algae mud of Chlorella and Chrysophylla; mix the algae mud of Chlorella and Chrysophylla according to the weight ratio of 1:1, and add 10% sterilized macroalgae powder, mixed evenly to obtain algae mixture;

[0043] (3) Add 1.8% compound microbial bacterial agent to the algae mixture, ferment for 24-36 hours at 32°C;

[0044] (4) After the fermentation is completed, add mannitol with a total weight of 5% to the fermented product, mix evenly, and vacuum freeze-dry to form a powder to obtain fermented algae powder.

[0045]The composite microbial bacterial agent is composed of Bacillus subtilis and Lactobacillus rhamnosus in a mass...

Embodiment 2

[0053] Activation of Aspergillus oryzae and Neurospora intertype and preparation of fermentation strains

[0054] Aspergillus oryzae BNCC195382, Beina Chuanglian Biotechnology Co., Ltd.;

[0055] Neurospora intertype BNCC149795, North Nachuanglian Biotechnology Co., Ltd.;

[0056] Aspergillus oryzae

[0057] Crush soybean shells through a 10-mesh sieve, and sterilize at 121°C for 15 minutes; adjust the water content to 50-65%, and inoculate the Aspergillus oryzae species activated by the bean juice slant medium into the peanut shell medium at an inoculation amount of 1%. Cultivate at 25-30°C for 48-60 hours to obtain fermentation strains with a content of ≥10 9 cfu·g -1 .

[0058] Neurospora intertype

[0059] Activation and fermentation medium: PDA medium;

[0060] Wash the Neurospora intertype spores on the slant medium with sterile water to prepare a spore suspension, the concentration of the spore suspension is 10 7 Individual / mL; spare.

Embodiment 3

[0062] A preparation method for fermented sunflower meal, the steps are as follows:

[0063] (1) After the sunflower seed meal is removed from impurities, it is mechanically crushed, passed through a 20-mesh sieve, and sterilized by high-pressure steam at 121°C for 30 minutes. After the sterilization is completed, cool to room temperature;

[0064] (2) Regulate the moisture content of the sunflower seed meal after sterilization to be 55-65%, inoculate the spore suspension of 8% Aspergillus oryzae and 7% Neurospora intertype in the peanut meal, after fully mixing, carry out solid-state fermentation, 28 ℃~32℃, ferment for 36 hours, then ferment for 24 hours at 32~35℃;

[0065] (3) Add 1 times the weight of deionized water to the material after the above-mentioned fermentation is completed, adjust pH 7.0, 40°C, enzymolysis 2h; adjust pH 4.5, 40°C, enzymolysis 4h; after enzymolysis, 100 ℃, treat for 10min, and cool to room temperature;

[0066] (4) Dry the material after enzymat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com