Preparation method of floor-heating electric heating plate

An electric heating plate and floor heating technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve problems such as leakage, short service life, high temperature safety, etc., and achieve broad application prospects, safety protection performance, and good temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

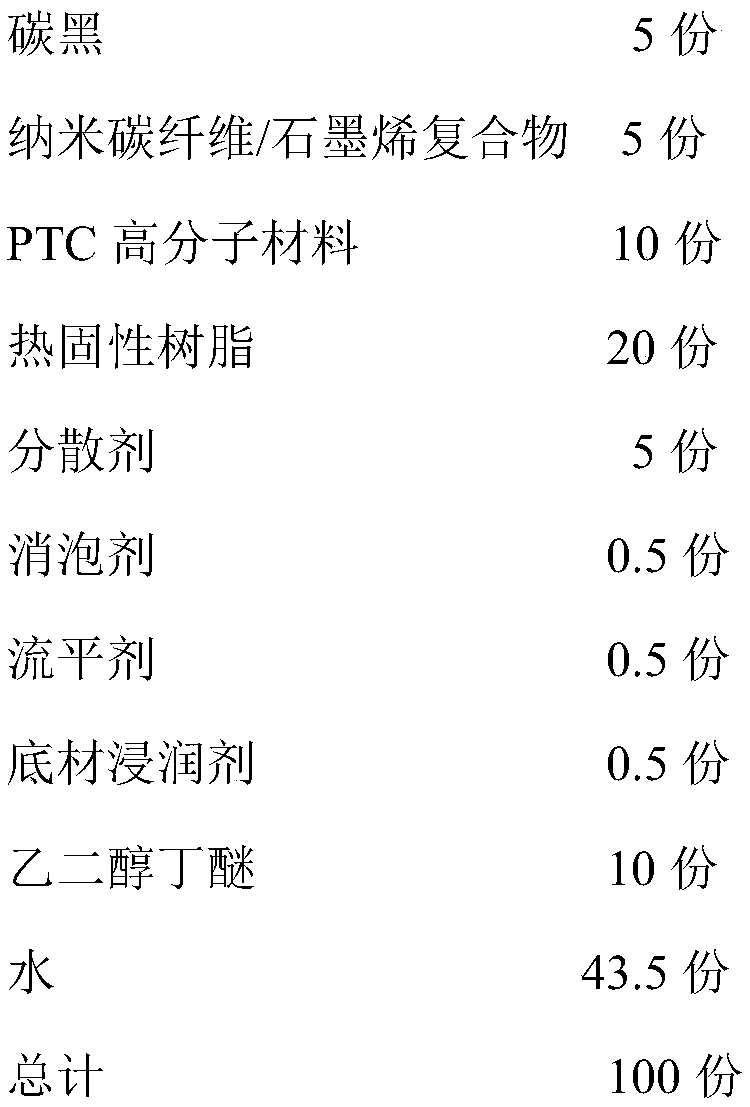

Embodiment 1

[0031] Step (1) preparation of gas-phase nano-carbon fiber / graphene:

[0032] Add 40mL concentrated sulfuric acid (H 2 SO 4 ) in 6g ammonium persulfate ((NH 4 ) 2 S 2 o 8 ), mechanically stirred until ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) dissolved, add 1.5g graphite powder (32 mesh), mechanically stir for 30min, slowly drop 5mLH 2 o 2, stand at room temperature to obtain intercalated graphite aggregates, wash with water until neutral, and dry; in a muffle furnace, expand at a high temperature of 550°C for 5 minutes to obtain graphene aggregates; crush in a jet mill until graphene powder is formed ;

[0033] Immerse the graphene powder into the ammonium nitrate aqueous solution, add the water mixed solution containing ferric nitrate and aluminum nitrate under stirring, stir and age for 2 hours, so that the Fe source and Al source are deposited on the surface of the graphene, filter, and dry. Send it to the muffle furnace at a high temperature of 550°C for 5 minu...

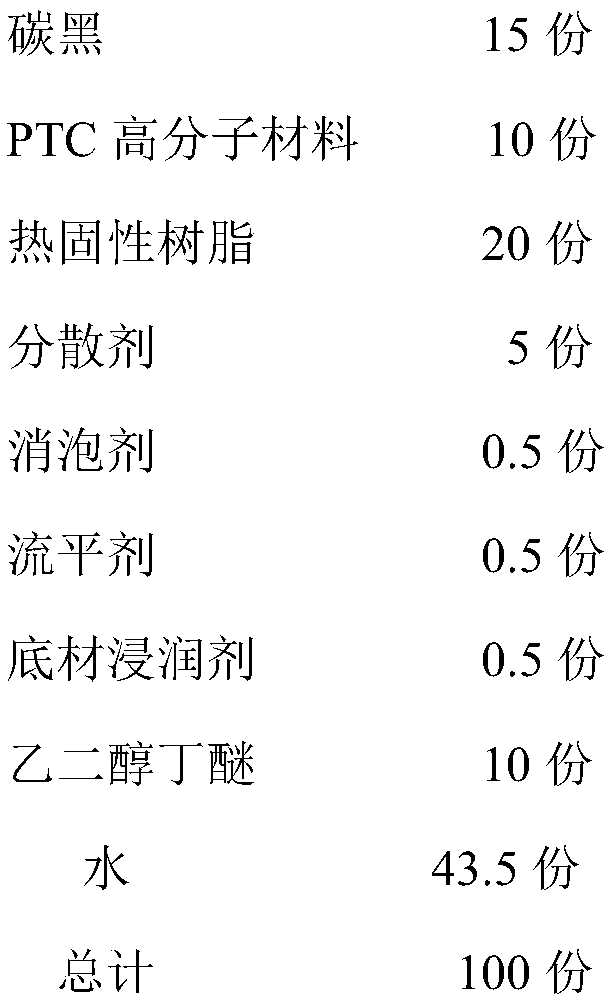

Embodiment 2

[0040] Step (2), step (3) are identical with embodiment 1. Step (1) is changed to:

[0041] Gas phase carbon nanofiber / graphene preparation:

[0042] Add 40mL concentrated sulfuric acid (H 2 SO 4 ) in 6g ammonium persulfate ((NH 4 ) 2 S 2 o 8 ), mechanically stirred until ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) dissolved, add 1.5g graphite powder (325 mesh), mechanically stir for 30min, slowly drop 5mLH 2 o 2 , stand at room temperature to obtain intercalated graphite aggregates, wash with water until neutral, and dry; in a muffle furnace, expand at a high temperature of 550 ° C for 10 minutes to obtain graphene aggregates; crush in a jet mill until graphene powder is formed ;

[0043] Immerse the graphene into the ammonium nitrate salt aqueous solution, add the water mixed solution containing ferric nitrate and aluminum nitrate under the stirring state, stir and age for 2 hours, so that the Fe source and the Al source are deposited on the surface of the graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com