New energy battery pack heat-conductive sealing material and preparation method thereof

A sealing material, battery pack technology, applied in sealing materials, battery pack components, electronic equipment, etc., can solve the problems of strong battery fluid corrosion, poor sealing performance, low thermal conductivity, etc., and achieve strong mechanical strength and insulation. performance, ensure the safety of use, and enhance the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

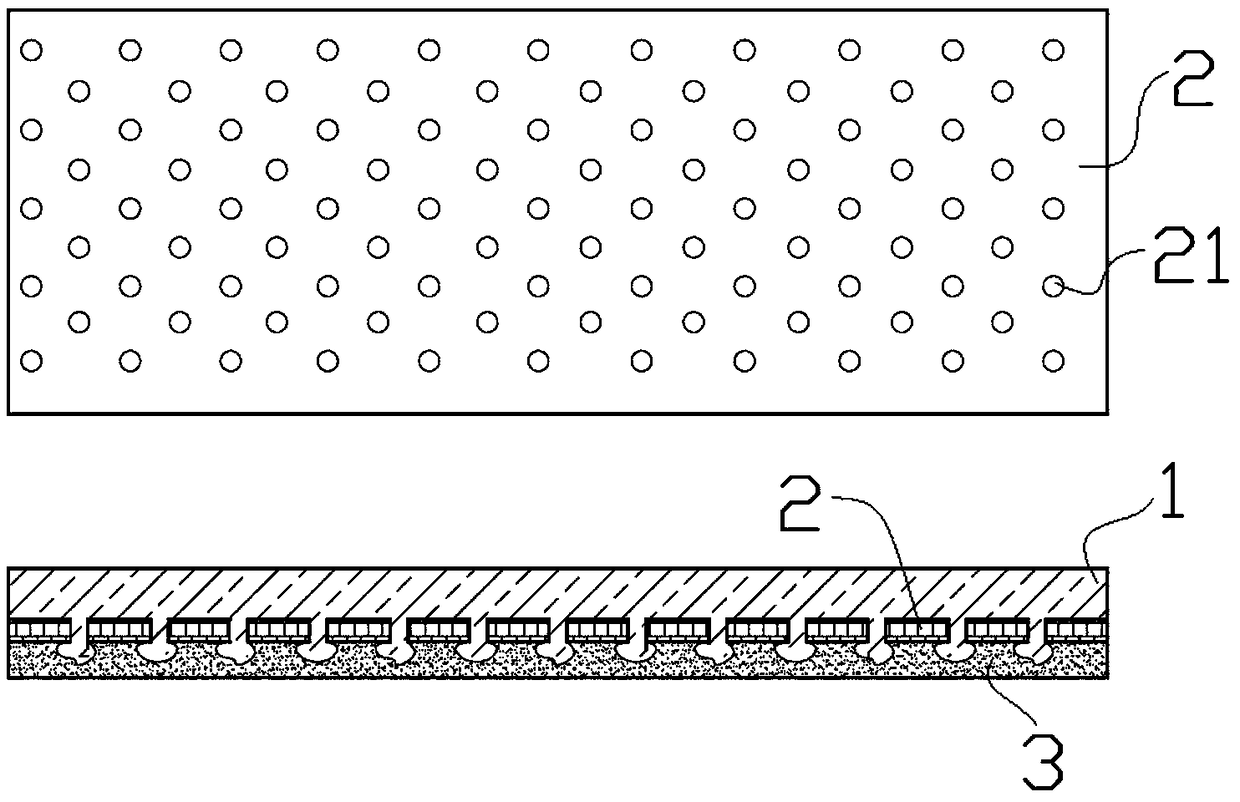

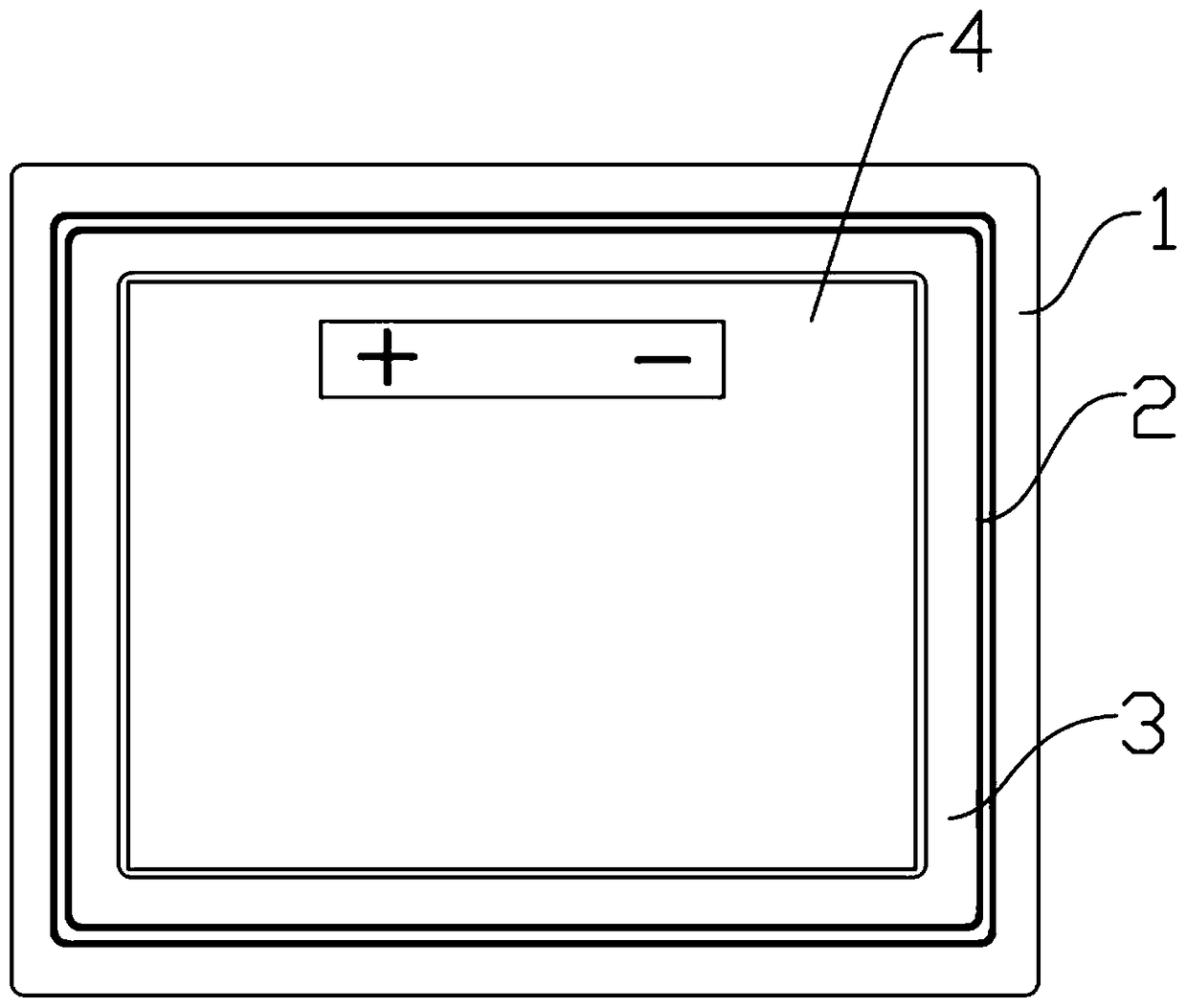

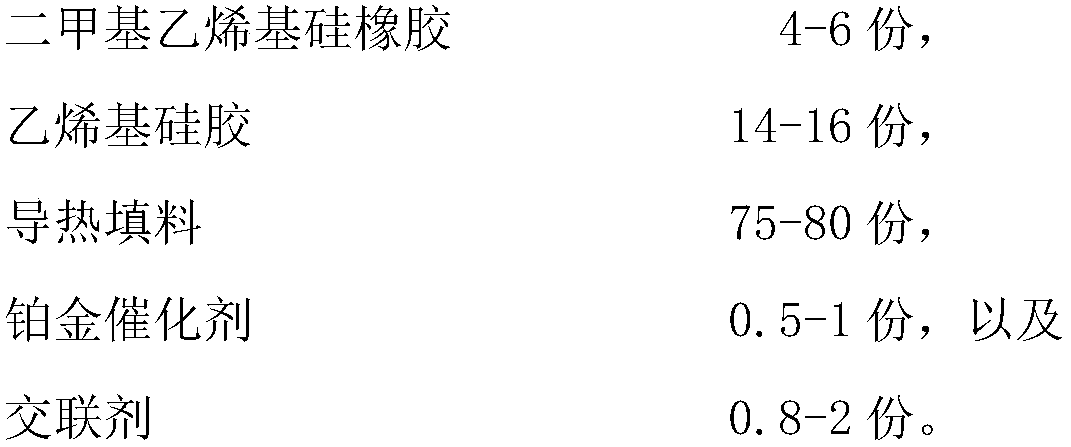

[0039] This embodiment 1 provides a thermally conductive sealing material for a new energy battery pack, including a thermally conductive silicone layer, a base material and a phase change thermally conductive layer integrally formed sealing material, the thermally conductive silicone layer is prepared from the following raw materials in parts by weight :

[0040]

[0041] Further, the crosslinking agent is hydrogen-containing organopolysiloxane, preferably methyl hydrogen-containing silicone oil, with a hydrogen content of 0.2% (by mass), and a viscosity of 800 mPa·s at 25°C.

[0042] Further, the thermally conductive filler is selected from a mixture of micron-sized alumina and zinc oxide.

[0043] The substrate is preferably a polyimide film (PI film), and the surface of the substrate is provided with several uniform composite holes.

[0044] Its preparation process is processed according to the following steps:

[0045] Step S1: Take the surface treatment agent and co...

Embodiment 2

[0050] This embodiment 1 provides a thermally conductive sealing material for a new energy battery pack, including a thermally conductive silicone layer, a base material and a phase change thermally conductive layer integrally formed sealing material, the thermally conductive silicone layer is prepared from the following raw materials in parts by weight :

[0051]

[0052] Further, the crosslinking agent is hydrogen-containing organopolysiloxane, preferably methyl hydrogen-containing silicone oil, with a hydrogen content of 0.25% (by mass), and a viscosity of 500 mPa·s at 25°C.

[0053] Further, the thermally conductive filler is selected from a mixture of micron-sized boron nitride, aluminum nitride and silicon nitride.

[0054] The substrate is preferably a polyimide film (PI film), and the surface of the substrate is provided with several uniform composite holes.

[0055] Its preparation process is processed according to the following steps:

[0056] Step S1: Take the ...

Embodiment 3

[0061] This embodiment 1 provides a thermally conductive sealing material for a new energy battery pack, including a thermally conductive silicone layer, a base material and a phase change thermally conductive layer integrally formed sealing material, the thermally conductive silicone layer is prepared from the following raw materials in parts by weight :

[0062]

[0063]

[0064] Further, the crosslinking agent is hydrogen-containing organopolysiloxane, preferably methyl hydrogen-containing silicone oil, with a hydrogen content of 0.3% (by mass), and a viscosity of 800 mPa·s at 25°C.

[0065] Further, the thermally conductive filler is selected from a mixture of micron-sized aluminum nitride, silicon nitride and aluminum powder.

[0066] The substrate is preferably a polyimide film (PI film), and the surface of the substrate is provided with several uniform composite holes.

[0067] Its preparation process is processed according to the following steps:

[0068] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com