Preparation method of medical titanium surface gradient nanometer silver

A surface gradient and nano-silver technology, which is applied in the direction of surface reaction electrolytic coating, medical science, electrolytic coating, etc., can solve the problems of cytotoxicity and affecting cell activity, and achieve short time consumption, simple process, easy realization and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

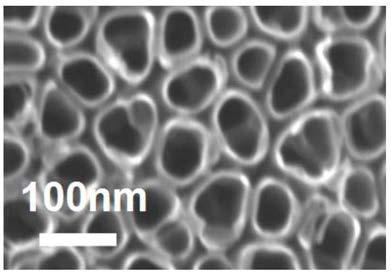

[0037] Cut the titanium foil into 2.5cm×4cm, ultrasonically clean it with acetone, ethanol, and deionized water for 20 minutes each, then dry it with a hair dryer, and store it in a ziplock bag for use. Prepare 100 ml of electrolytic solution for traditional electrochemical anodic oxidation, which solution contains 0.5 wt% hydrofluoric acid. The titanium foil was submerged in the electrolyte, the voltage was 15V, and the oxidation time was 20min. After the reaction was completed, it was taken out and rinsed with deionized water and dried. At this time, a layer of TiO in a regular array is obtained on the surface of the titanium foil. 2 Nanotubes with a diameter of about 80nm, such as figure 2 shown.

[0038] The titanium foil modified with titanium dioxide nanotubes was cut into 2.5cm×1cm and used as a bipolar electrode. Fix the titanium bipolar electrode horizontally at the bottom of the electrolytic cell, and its two ends are 1mm away from the two platinum electrodes. Po...

Embodiment 2

[0040]Repeat all the steps in Example 1 to prepare gradient nano-silver micropattern samples. The prepared sample was irradiated under ultraviolet light for more than 30 minutes, and the MC3T3-E1 cells were irradiated at a density of 1.0×10 5 Inoculate on the sample at a density of one / ml and incubate in a 37°C incubator for 24h. Fluorescent staining with Calcein-AM, observed with an inverted fluorescence microscope under blue light excitation, as shown in Figure 7-10 As shown, the number of adhered cells gradually increased with the increase of nano-silver particle size.

Embodiment 3

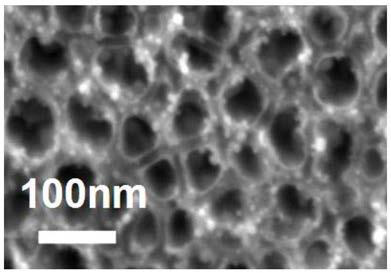

[0042] The gradient nano-silver micropattern sample prepared by repeating all the steps in Example 1. The prepared samples were soaked in alcohol for 30 min and then rinsed with PBS. Staphylococcus aureus at a density of 1.0×10 6 ~1.0×10 7 Inoculate on the sample at a density of one / ml and incubate in a 37°C incubator for 6h. After taking it out, wash it with PBS for 3 times, fix it with 2.5% glutaraldehyde solution in a refrigerator at 4°C for 2 hours, and then use 30%, 50%, 75%, 90%, and 100% absolute ethanol to carry out gradient dehydration successively. The samples were submerged in tert-butanol, frozen in a refrigerator at -20°C, and then placed in a lyophilizer to freeze-dry. The samples were sprayed with gold and observed under a scanning electron microscope. Such as Figures 11-14 As shown, the number of bacteria gradually increased with the increase of nano-silver particle size.

[0043] The present invention cleans the titanium foil and uses an electrochemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com