Water-based high-barrier coating liquid and high-barrier film thereof

A high-barrier film and coating solution technology, which is applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problem of poor compatibility between inorganic nanoparticles and polyvinyl alcohol, and changes in the aggregated structure of polyvinyl alcohol , affecting the transparency of the film, etc., to achieve excellent retort resistance, low requirements for coating equipment, and enhanced compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

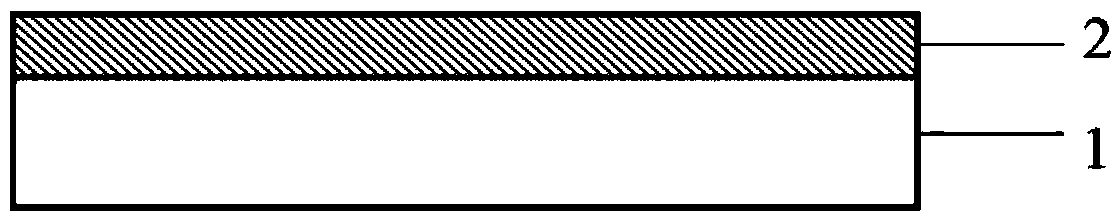

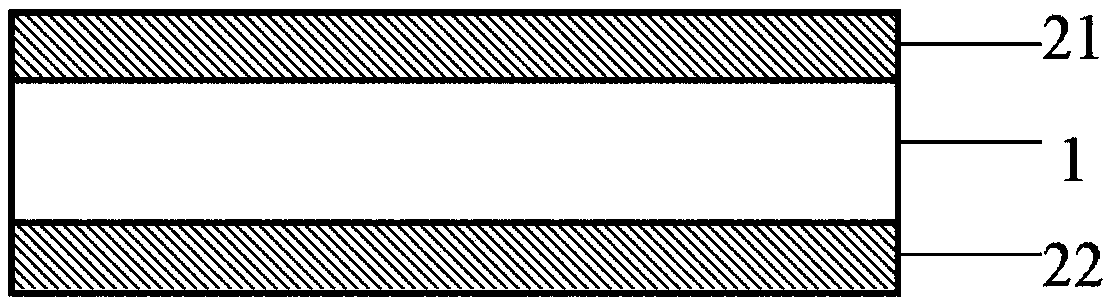

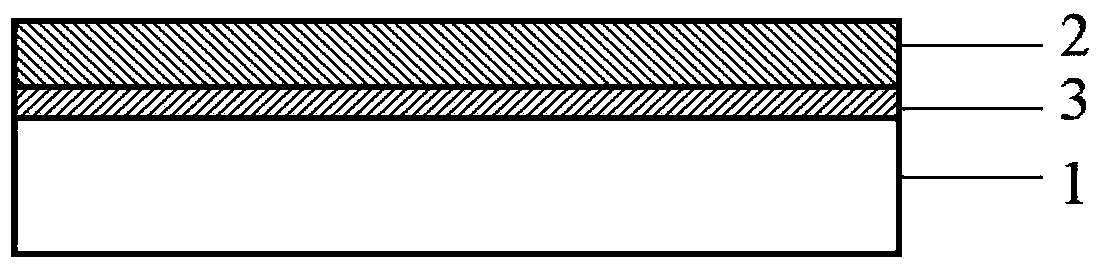

Image

Examples

Embodiment 1

[0048] Add 50g of PVA (alcoholysis degree 99%, polymerization degree 2400) into 900g water and 50g methanol and stir evenly, first swell in a 50°C water bath for 20min, then stir in a 95°C water bath for 30min to dissolve, and obtain a solid content of 5.0 % PVA solution a1 component.

[0049] Mix 360g of TEOS (purity 99.9%), 170g of methanol, 468g of water, and 2.0g of hydrochloric acid (0.1% by mass fraction) together, stir at room temperature for 1h to carry out hydrolysis and condensation, and obtain a nano-silica dispersion with a solid content of 10.4%. b1 component (as SiO 2 count).

[0050] Mix 30g of A187 (purity 99.9%), 400g of isopropanol, 569g of water, and 1.0g of hydrochloric acid (0.1% by mass fraction) together, stir at room temperature for 1h for hydrolysis, and obtain a coupling agent with a solid content of 2.5%. Hydrolyzate c1 (in YR 3 Si(OH) 3 count).

[0051] Add 700g of 10.4% nano-silica dispersion liquid b1 component and 100g of 2.5% coupling agent...

Embodiment 2

[0054] The preparation method of PVA solution and nano silicon oxide dispersion liquid is identical with embodiment 1.

[0055] Mix 35g of A171 (purity 99.9%), 460g of isopropanol, 504g of water, and 1.0g of hydrochloric acid (0.1% by mass fraction) together, stir at room temperature for 1h for hydrolysis, and obtain a coupling agent with a solid content of 3.4%. Hydrolyzate c2 (in YR 3 Si(OH) 3 count).

[0056] Add 700g of 10.4% nano-silicon oxide dispersion solution b1 component and 100g of 3.4% coupling agent hydrolyzate c2 component in sequence, after stirring rapidly for 20min, add 200g of 5.0% PVA solution a1 component, and continue to rapidly Stir for 30 minutes, and add 10g of retarding crosslinking agent sodium sulfate, 5g of leveling agent Silok8000, and 5g of adhesion promoter Silok628 at the same time to obtain high barrier coating solution TC-2.

[0057] On a micro-gravure coater, apply TC-2 coating liquid on the surface of the coating layer on which the base f...

Embodiment 3

[0059] The preparation method of PVA solution and nano silicon oxide dispersion liquid is identical with embodiment 1.

[0060] Mix 29g of A174 (purity 99.9%), 470g of isopropanol, 500g of water, and 1.0g of hydrochloric acid (0.1% by mass fraction) together, stir at room temperature for 1h for hydrolysis, and obtain a coupling agent with a solid content of 2.4%. Hydrolyzate c3.

[0061] Add 700g of 10.4% nano-silica dispersion solution b1 component and 100g of 2.4% coupling agent hydrolyzate c3 component in sequence, after stirring rapidly for 20min, add 200g of 5.0% PVA solution a1 component, and continue to rapidly Stir for 30 minutes, and at the same time add 10 g of retarding crosslinking agent sodium sulfate, 5 g of leveling agent Silok8000, and 5 g of adhesion promoter Silok628 to obtain high barrier coating solution TC-3.

[0062] On a micro-gravure coater, apply TC-3 coating liquid on the surface of the coating layer whose base film is 12 μm PET and has deposited 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com