Cf/HfC-TaC-C composite material and preparation method thereof

A composite material, hfc-tac-c technology, which is applied in the field of ceramic matrix composite materials, can solve the problems of unsatisfactory mechanical properties and inability to meet high-temperature use environments, and achieve easy industrial implementation, outstanding mechanical properties, and excellent ablation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

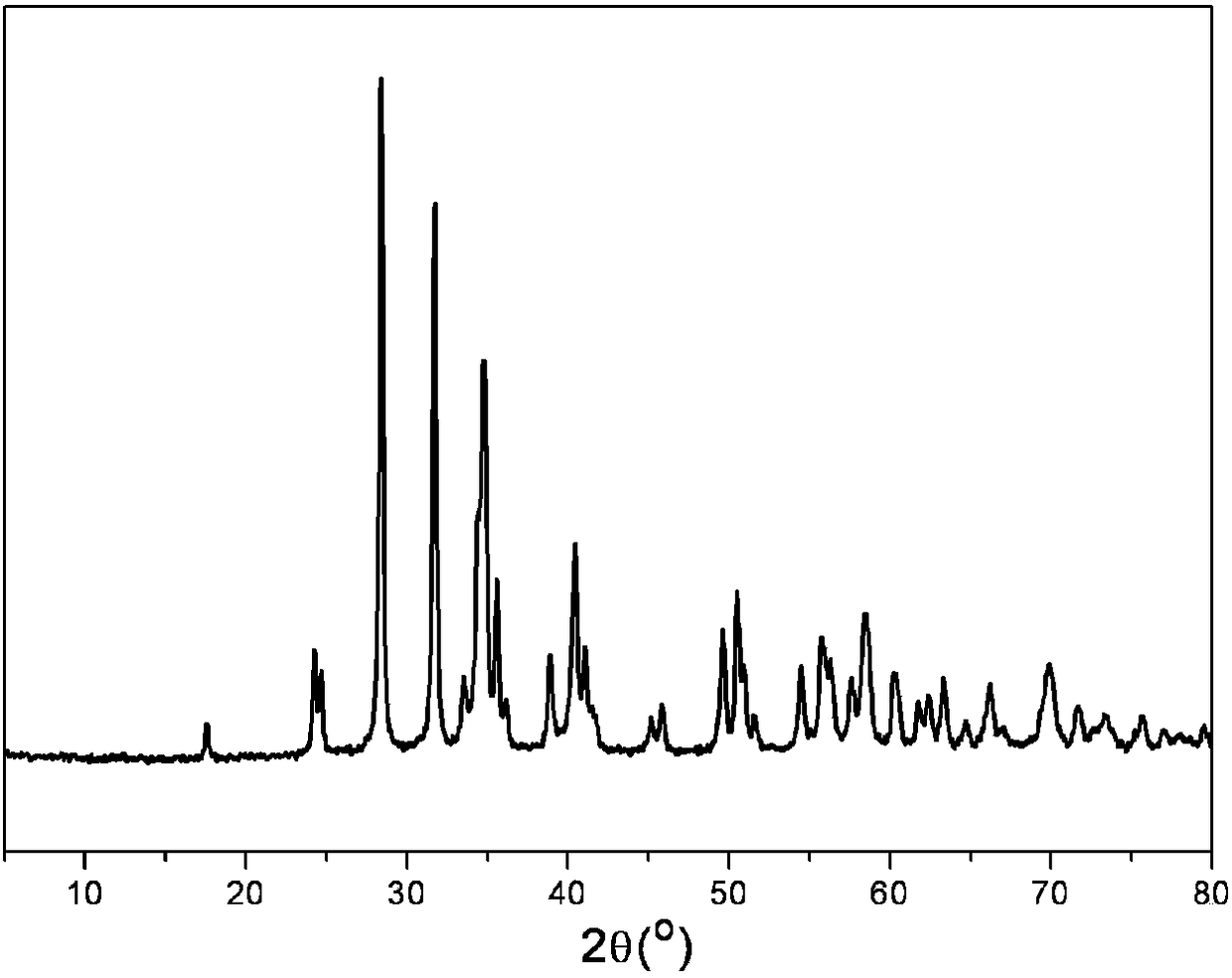

Image

Examples

Embodiment 1

[0037] a C f / HfC-TaC-C composite material preparation method, using the impregnation pyrolysis method (PIP) of hafnium-tantalum precursor to prepare dense C f / HfC-TaC-C composite material, its specific steps are:

[0038] 1) The needle-punched carbon fiber preform was treated at a high temperature of 1700°C for 3 hours, and then deposited in a vapor deposition furnace for 100 hours, 150 hours, and 80 hours, so that the density of the preform reached 1.05g / cm 3 .

[0039] 2) Immerse the above-mentioned prefabricated body under a vacuum of 50KPa for 1 hour, then under a pressure of 3MPa for 1 hour, and finally pressurize to 10MPa, and raise the temperature to 100°C for 1 hour, and 200°C for 1 hour, Insulate at 350° C. for 1 hour to fully cross-link and solidify the hafnium-tantalum precursor.

[0040] 3) Put the solidified carbon fiber preform in a pyrolysis furnace, and pyrolyze at 1600° C. for 3 hours under an argon atmosphere.

[0041] 4) Repeat steps 2) and 3) 8 times, t...

Embodiment 2

[0047] a C f / HfC-TaC-C composite material preparation method, using the impregnation pyrolysis method (PIP) of hafnium-tantalum precursor to prepare dense C f / HfC-TaC-C composite material, its specific steps are:

[0048] 1) Treat the fine-woven and punctured carbon fiber preform at a high temperature of 1700°C for 3 hours, and then deposit it in a vapor deposition furnace for 80 hours, 100 hours, and 80 hours respectively, so that the density of the preform reaches 1.12g / cm 3 .

[0049] 2) Immerse the above-mentioned prefabricated body under a vacuum of 50KPa for 1 hour, then under a pressure of 3MPa for 1 hour, and finally pressurize to 10MPa, and raise the temperature to 100°C for 1 hour, and 200°C for 1 hour, Insulate at 350° C. for 1 hour to fully cross-link and solidify the hafnium-tantalum precursor.

[0050] 3) Put the solidified carbon fiber preform in a pyrolysis furnace, and pyrolyze at 1600° C. for 3 hours under an argon atmosphere.

[0051] 4) Repeat steps 2...

Embodiment 3

[0056] a C f / HfC-TaC-C composite material preparation method, using the impregnation pyrolysis method (PIP) of hafnium-tantalum precursor to prepare dense C f / HfC-TaC-C composite material, its specific steps are:

[0057] 1) The stitched carbon fiber preform was treated at a high temperature of 1700°C for 3 hours, and then deposited in a vapor deposition furnace for 100 hours, 120 hours, and 80 hours respectively, so that the density of the preform reached 1.18g / cm 3

[0058] 2) Immerse the above-mentioned prefabricated body under a vacuum of 50KPa for 1 hour, then under a pressure of 3MPa for 1 hour, and finally pressurize to 10MPa, and raise the temperature to 100°C for 1 hour, and 200°C for 1 hour, Insulate at 350° C. for 1 hour to fully cross-link and solidify the hafnium-tantalum precursor.

[0059] 3) Put the solidified carbon fiber preform in a pyrolysis furnace, and pyrolyze at 1600° C. for 3 hours under an argon atmosphere.

[0060] 4) Repeat steps 2) and 3) 8 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com