a nd 2 fe 14 Preparation method and application of b/al composite material

A technology of nd2fe14b and composite materials, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, and the magnetism of inorganic materials. Simple process and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

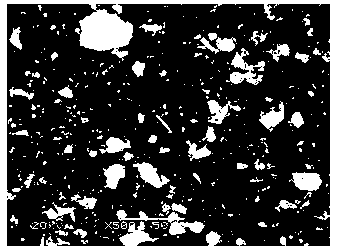

Image

Examples

Embodiment 1

[0037] (1) Ball milling:

[0038] The Al powder used in the experiment is a powder of 99.85% purity, and the average particle diameter is 10 μm; the NdFeB powder particle size is 15 μm, and the purity is 99.9%; 45g aluminum powder and 15g NdFeB (NdFeB) 2 Fe 14 B) powder mixing, adding 5% ethanol of the above-mentioned mixed powder quality, wet grinding in a planetary ball mill for 12 hours, putting the ball-milled powder into a vacuum drying oven to dry, and obtaining a mixed fine powder;

[0039] (2) Compression molding:

[0040] The mixed fine powder in the step (1) is compressed by cold isostatic pressing, pressurized at 100 MPa, and kept under pressure for 1 min to obtain a dense composite billet;

[0041] (3) Flash sintering:

[0042]Put the composite ingot in a vacuum flash furnace and connect it in series to the circuit for flash sintering, and raise the temperature to 550°C at 5°C / min. With a field strength of 100V / cm, when the temperature reaches a constant temper...

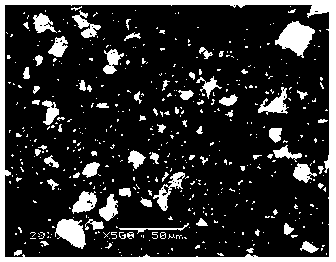

Embodiment 2

[0047] (1) Ball milling:

[0048] The Al powder used in the experiment is a powder of 99.85% purity, and the average particle diameter is 10 μm; the particle size of NdFeB powder is 15 μm, and the purity is 99.9%; 50g aluminum powder and 10g NdFeB (NdFeB) 2 Fe 14 B) powder mixing, adding 5% ethanol of the above-mentioned mixed powder quality, wet grinding in a planetary ball mill for 10 hours, putting the ball-milled powder into a vacuum drying oven to dry, and obtaining a mixed fine powder;

[0049] (2) Compression molding:

[0050] The mixed fine powder in the step (1) is compressed by cold isostatic pressing, pressurized at 105MPa, and kept under pressure for 1.5min to obtain a dense composite billet;

[0051] (3) Flash sintering:

[0052] Put the composite ingot in a vacuum flash furnace and connect it in series to the circuit for flash sintering, and raise the temperature to 580°C at 5°C / min. With a field strength of 1000V / cm, when the temperature reaches a constant t...

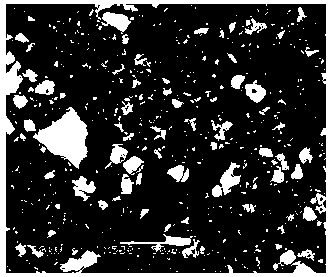

Embodiment 3

[0057] (1) Ball milling:

[0058] The Al powder used in the experiment is a powder of 99.85% purity, and the average particle diameter is 10 μm; the NdFeB powder particle size is 15 μm, and the purity is 99.9%; 56g aluminum powder and 8g NdFeB (NdFeB) 2 Fe 14 B) powder mixing, adding 5% ethanol of the above-mentioned mixed powder quality, wet grinding in a planetary ball mill for 11 hours, putting the ball-milled powder into a vacuum drying oven to dry, and obtaining a mixed fine powder;

[0059] (2) Compression molding:

[0060] The mixed fine powder in the step (1) is compressed by cold isostatic pressing, pressurized at 110MPa, and kept under pressure for 1min to obtain a dense composite billet;

[0061] (3) Flash sintering:

[0062] Put the composite ingot in a vacuum flash furnace and connect it in series to the circuit for flash sintering, raise the temperature to 610°C at 5°C / min, and at the same time start to heat up, apply 2000V, 5A power to the composite ingot Wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com