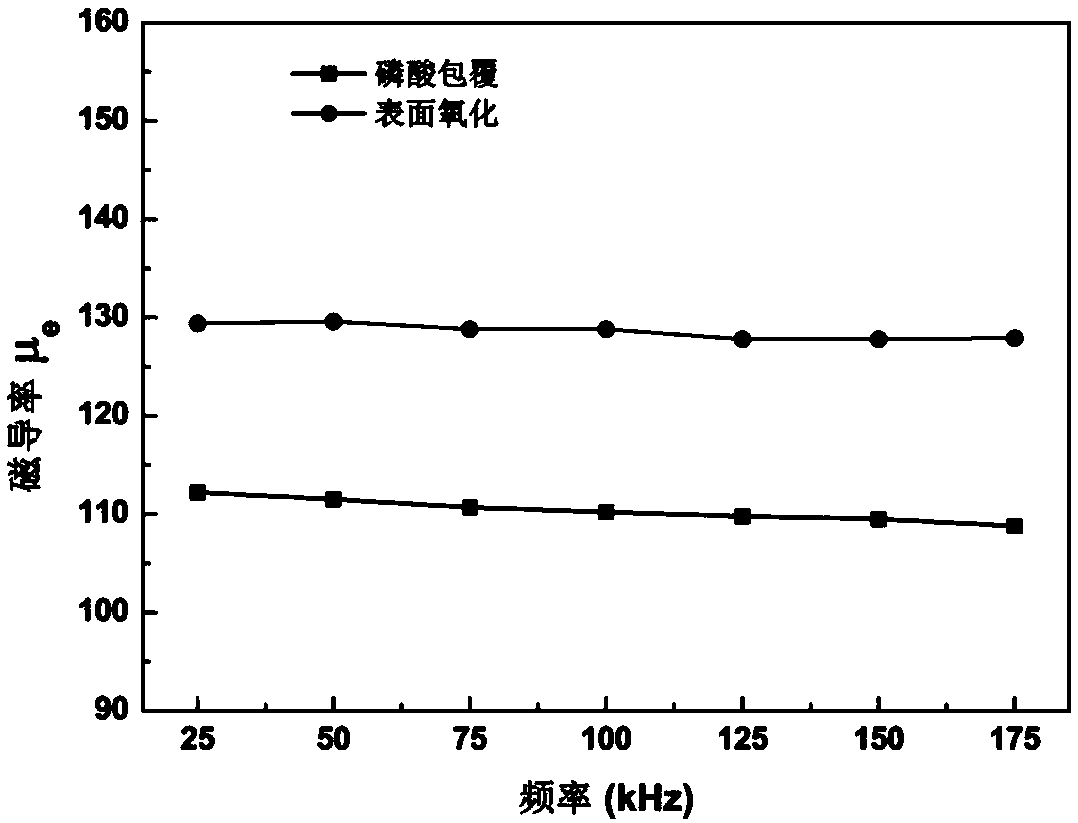

A method for fabricating metal soft magnetic composites with high permeability and low power consumption by surface oxidation process

A composite material and surface oxidation technology, which is applied in the fields of metal processing equipment, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of low heat resistance temperature, poor bonding of insulating film, etc., and achieve low production cost and magnetic Small dilution effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 9 g of sodium nitrite to 30 g of deionized water, add a buffer solution prepared by acetic acid and sodium acetate, adjust the pH of the solution to 4, and stir evenly for 20 min to obtain an oxidation solution. After sieving 15 g of iron powder for particle size proportioning, add it to the passivation solution and stir uniformly for 20 minutes, then filter and dry to obtain oxidized magnetic powder. The oxidized magnetic powder is added with a binder that accounts for 1.0% of the mass of the oxidized magnetic powder, and the mixture is fully stirred under heating until the mixture is dry and uniform. The binder is silicone resin. Then, 0.5% of the total weight of the oxidized magnetic powder is added to the oxidized magnetic powder with a mold release agent that is evenly mixed. The mold release agent is zinc stearate to obtain the magnetic powder to be molded. The magnetic powder to be formed is pressed into a ring-shaped soft magnetic composite material with an o...

Embodiment 2

[0028] Add 6 g of sodium nitrate to 20 g of deionized water, add a buffer solution prepared by acetic acid and sodium acetate, adjust the pH of the solution to 6, and stir evenly for 30 minutes to obtain an oxidation solution. Pass 20 g sendust powder through a sieve for particle size proportioning and add it to the passivation solution, while uniformly stirring for 30 min, then filter and dry to obtain oxidized magnetic powder. A binder accounting for 1.5% of the mass of the oxidized magnetic powder is added to the oxidized magnetic powder, and the mixture is fully stirred under heating until the mixture is dry and uniformly mixed. The binder is a phenolic resin. Then, a release agent that accounts for 1.0% of the total weight of the oxidized magnetic powder is added to the oxidized magnetic powder and mixed uniformly. The release agent is barium stearate to obtain the magnetic powder to be molded. Press the magnetic powder to be formed into a ring-shaped soft magnetic composi...

Embodiment 3

[0036] Add 10 g of potassium permanganate to 25 g of deionized water, add a buffer solution prepared by acetic acid and sodium acetate, adjust the pH of the solution to 5, and stir evenly for 30 min to obtain an oxidation solution. After sieving 25 g of iron-silicon powder for particle size proportioning, add it to the passivation solution and stir it evenly for 40 minutes, then filter and dry to obtain oxidized magnetic powder. The oxidized magnetic powder is added with a binder that accounts for 2.0% of the mass of the oxidized magnetic powder, and the mixture is fully stirred under heating until the mixture is dry and uniform. The binder is silicone resin. Then, a release agent accounting for 1.5% of the total weight of the oxidized magnetic powder is added to the oxidized magnetic powder and mixed uniformly. The release agent is zinc stearate to obtain the magnetic powder to be molded. The magnetic powder to be formed is pressed into a ring-shaped soft magnetic composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com