Forklift pressure closed-loop control method and control system using same

A closed-loop control, forklift technology, used in fluid pressure actuation system testing, fluid pressure actuation devices, servo motors, etc., can solve the problems of high energy consumption, large flow loss, large pressure loss, etc. The effect of low power consumption, reduced output flow, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

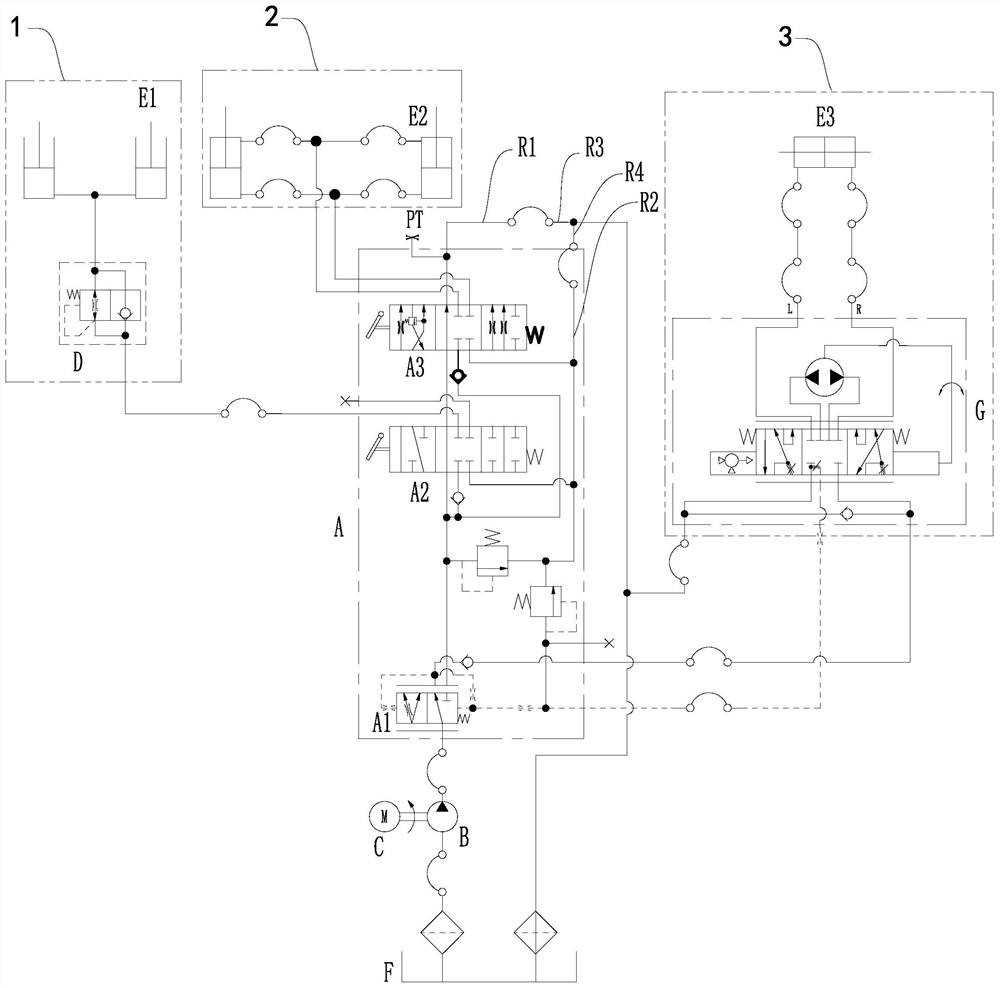

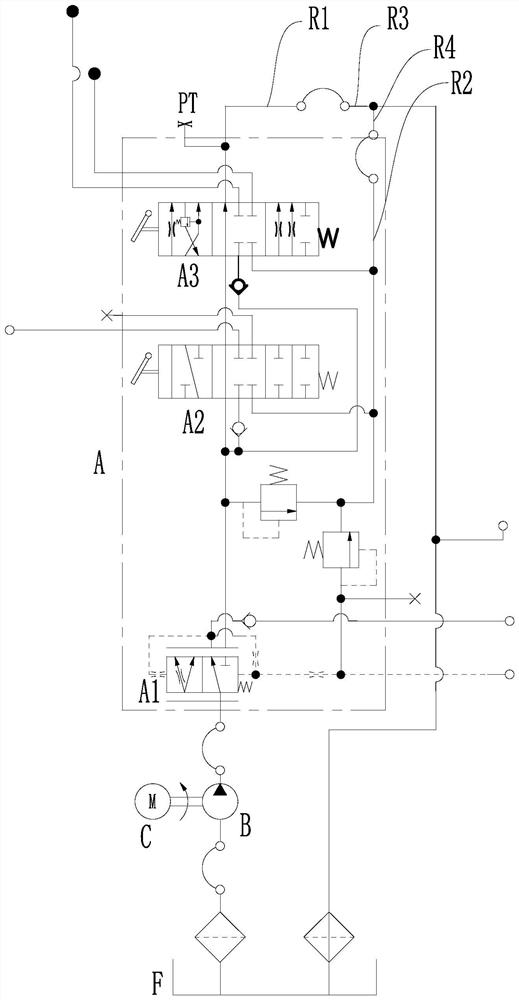

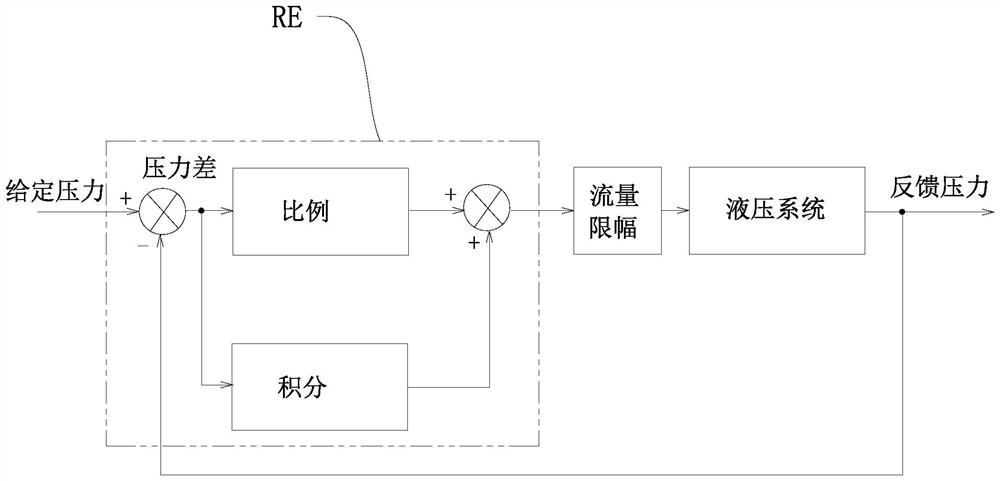

[0030] A forklift pressure closed-loop control method proposed in this embodiment, such as figure 1 and image 3 shown, it includes the following steps:

[0031] Step 1: On the basis of the forklift pressure control oil circuit, a bypass oil return circuit R1 is added to the three-piece multi-way valve A, and the oil inlet of the bypass oil return oil line R1 is connected to the three-piece multi-way valve. In A, the oil outlet of the straight oil passage connecting the first piece A1, the second piece A2 and the third piece A3 is connected, and the main oil return oil passage R2 in the three-piece multi-way valve A is connected with the three-piece type In the multi-way valve A, the oil outlet of the straight oil passage connecting the first piece A1, the second piece A2 and the third piece A3 is not connected, and the oil outlet of the bypass oil return oil passage R1 passes through the bypass oil return oil pipe R3 Connect with the fuel tank F; then connect a pressure sen...

Embodiment 2

[0042] This embodiment proposes a control system using the forklift pressure closed-loop control method of the first embodiment, such as figure 1 and figure 2 As shown, it includes a hoisting oil circuit 1 used to realize the lifting and lowering of heavy objects by a forklift, an inclined oil circuit 2 used to realize the forklift tilting forward and backward leaning the heavy objects, a steering oil circuit 3 used to realize the steering of the forklift truck, and a gear pump. B. Motor C, fuel tank F, forklift controller, and three-piece multi-way valve A, three-piece multi-way valve for distributing hydraulic oil flow to hoisting oil circuit 1, tilting oil circuit 2, and steering oil circuit 3 A has a first sheet body A1, a second sheet body A2 and a third sheet body A3, the three-piece multi-way valve A is provided with a main oil return oil circuit R2, and the three-piece multi-way valve A is additionally provided with a bypass oil return The oil passage R1, the oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com