A lithium alloy strip and a preparation method thereof

A lithium alloy and strip technology, applied in the field of lithium alloy strip and its preparation, can solve the problems of easy adhesion of metal lithium, low coulombic efficiency, short life, etc., and achieve good affinity, improved coulombic efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

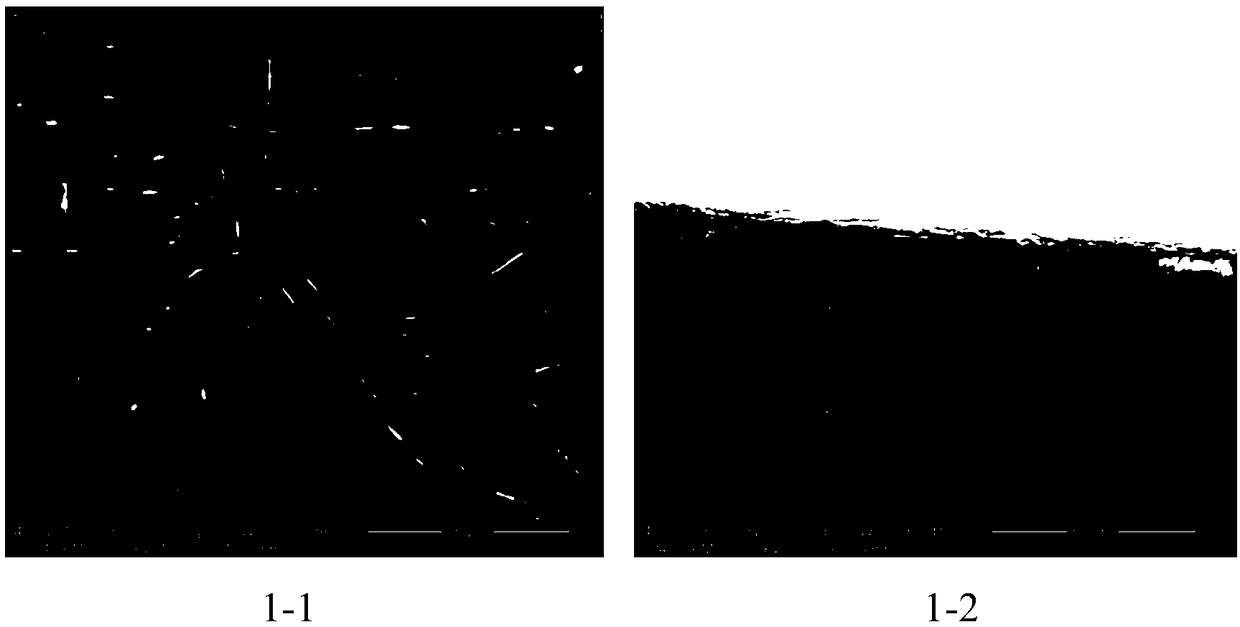

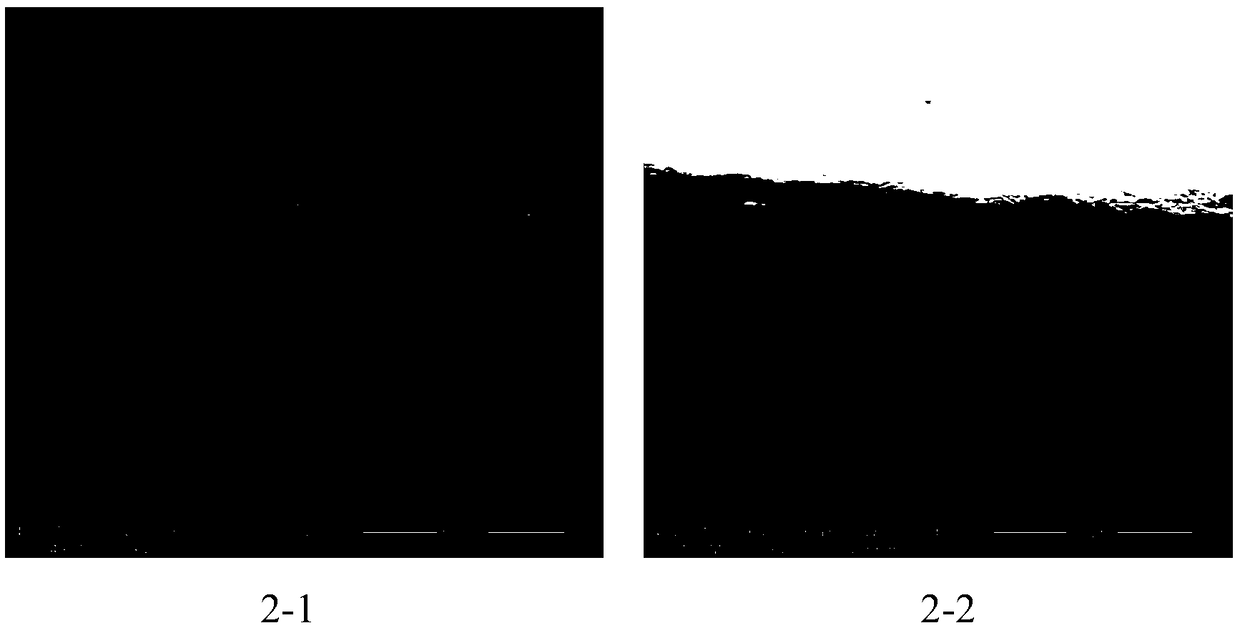

Embodiment 1

[0045] A metal lithium alloy strip is self-supporting, and its interior includes a uniformly mixed metal lithium element and a transition metal element with a micro-nano structure, and at the same time, the metal lithium element is filled in the transition metal element with a network structure.

[0046] Its preparation method is as follows:

[0047] (1) In an environment with a dew point of -50°C and an oxygen content of 10ppm, the lithium metal is heated to 200°C, and the lithium metal is in a molten state at this time;

[0048] (2) Under the condition that the temperature is lower than the melting point of the transition metal, add the transition metal copper to the metal lithium in the molten state, keep it warm for 10 minutes, and mix well to make the metal lithium form a molten alloy state, wherein the number of atoms of copper and lithium The ratio is 1:100;

[0049] (3) cooling the metallic lithium alloy in molten state in step (2) to room temperature within 5min to o...

Embodiment 2

[0053] A metal lithium alloy strip is self-supporting, and its interior includes a uniformly mixed metal lithium element and a transition metal element with a micro-nano structure, and at the same time, the metal lithium element is filled in the transition metal element with a network structure.

[0054] Its preparation method is as follows:

[0055] (1) In an environment with a dew point of -60°C and an oxygen content of 2ppm, the metal lithium is heated to 200°C, and the metal lithium is in a molten state at this time;

[0056] (2) Under the condition that the temperature is lower than the melting point of the transition metal, add the transition metal copper to the metal lithium in the molten state, keep it warm for 10 minutes, and mix well to make the metal lithium form a molten alloy state, wherein the number of atoms of copper and lithium The ratio is 1:60;

[0057] (3) cooling the metal lithium alloy in molten state in step (2) to room temperature within 5min to obtain...

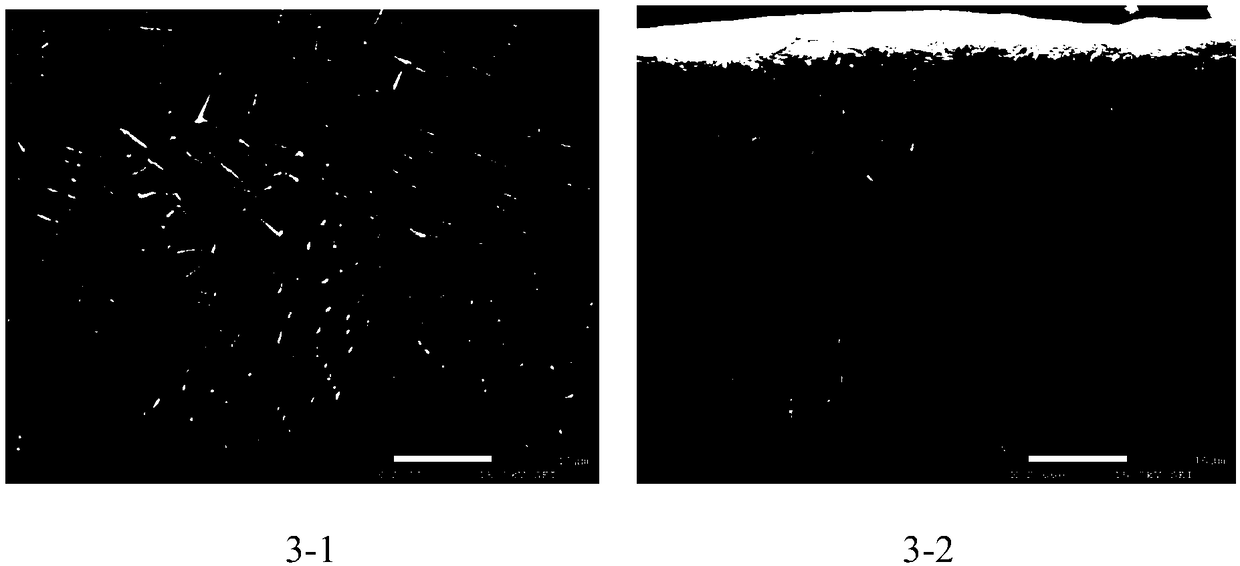

Embodiment 3

[0061] A metal lithium alloy strip is self-supporting, and its interior includes a uniformly mixed metal lithium element and a transition metal element with a micro-nano structure, and at the same time, the metal lithium element is filled in the transition metal element with a network structure.

[0062] Its preparation method is as follows:

[0063] (1) In an environment with a dew point of -70°C and an oxygen content of 1ppm, the lithium metal is heated to 800°C, and the lithium metal is in a molten state at this time;

[0064] (2) Under the condition that the temperature is lower than the melting point of the transition metal, add the transition metal copper to the metal lithium in the molten state, keep it warm for 10 minutes, and mix well to make the metal lithium form a molten alloy state, wherein the number of atoms of copper and lithium The ratio is 2:3;

[0065] (3) cooling the metallic lithium alloy in molten state in step (2) to room temperature within 5min to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com