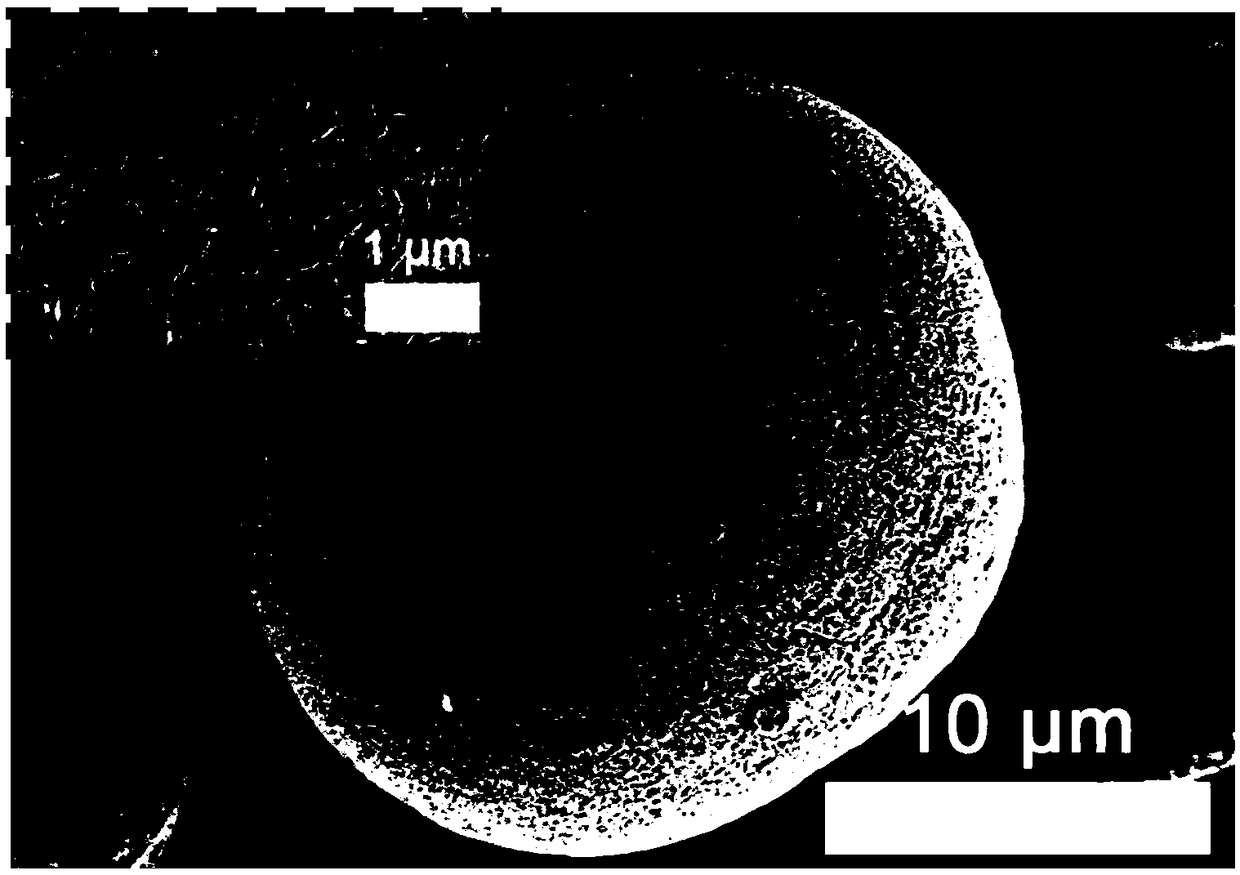

A NCM ternary cathode material with hierarchical structure

A cathode material and hierarchical structure technology, applied in the field of nickel-cobalt-manganese ternary cathode materials, can solve the problems of waste, phase separation, and unfavorable material commercialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Step (1): Weigh NiSO according to the molar ratio Ni:Co:Mn=8:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, use 100mL deionized water to make the total concentration of transition metal ions is 2mol L -1 mixed metal salt solution, and then use 200mL deionized water to prepare NaOH and ammonia water at a molar ratio of 1:1 to make the NaOH concentration 2mol L -1 mixed alkaline solution.

[0076] Step (2): Add 50mL deionized water to the continuous stirred tank reactor as the reaction base liquid, and add Ni which accounts for 5% of the total molar weight of the metal salt in the mixed metal salt solution. 0.90 co 0.06 mn 0.04 (OH) 2 As a nucleating agent, add ammonia water dropwise after stirring for 10 minutes, adjust the pH of the reaction base solution to about 11, pass in argon as a protective gas, set the stirring speed at 500r / min, and set the reaction temperature at 55°C. Slowly pump the metal salt solution and the mixed alkali solution into the react...

Embodiment 2

[0089] Step (1): Weigh NiSO according to the molar ratio Ni:Co:Mn=8:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, use 100mL deionized water to make the total concentration of transition metal ions is 2mol L -1mixed metal salt solution, and then use 200mL deionized water to prepare NaOH and ammonia water at a molar ratio of 1:1 to make the NaOH concentration 2mol L -1 mixed alkaline solution.

[0090] Step (2): Add 50mL deionized water to the continuous stirred tank reactor as the reaction base liquid, add Ni which accounts for 10% of the total molar weight of the metal salt in the mixed metal salt solution 0.90 co 0.06 mn 0.04 (OH) 2 As a nucleating agent, add ammonia water dropwise after stirring for 10 minutes, adjust the pH of the reaction base solution to about 11, pass in argon as a protective gas, set the stirring speed at 500r / min, and set the reaction temperature at 55°C. Slowly pump the metal salt solution and the mixed alkali solution into the reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com