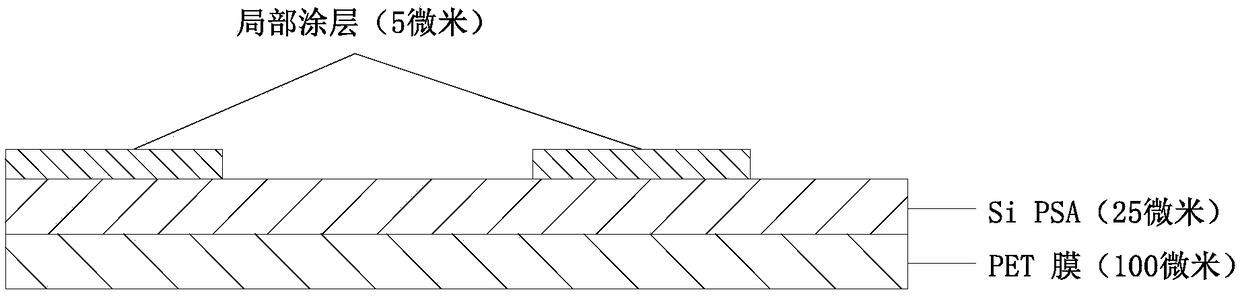

Photo-cured epoxy-modified organic silicon coating composition and preparation method thereof

A technology of silicone coating and epoxy modification, applied in the direction of coating, can solve the problems of reducing the overall heat resistance of silicone materials, poor brittleness and toughness, and sticky material surface, so as to facilitate construction and customer use. , The effect of strong anti-vibration ability and excellent surface dry performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

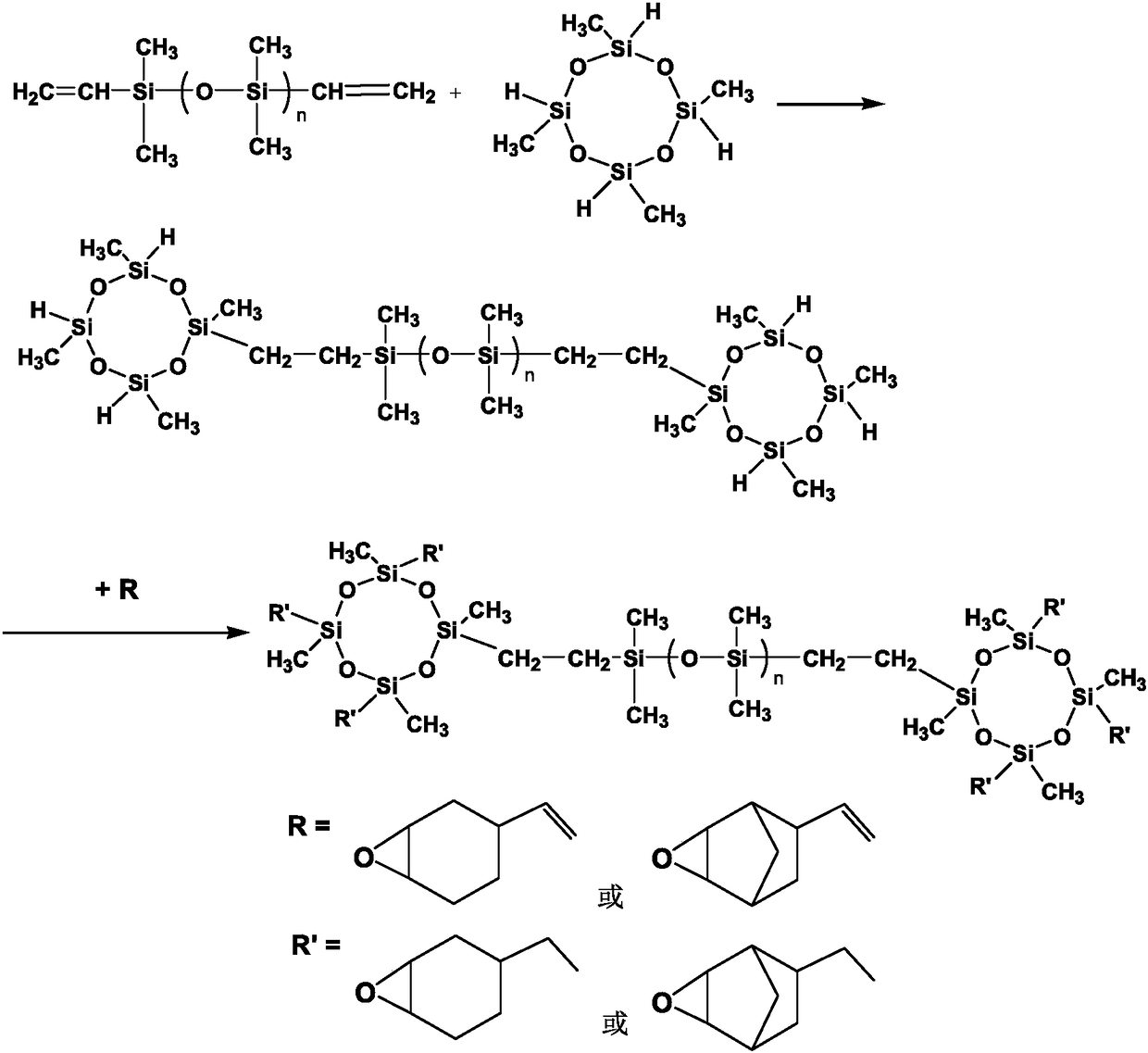

Method used

Image

Examples

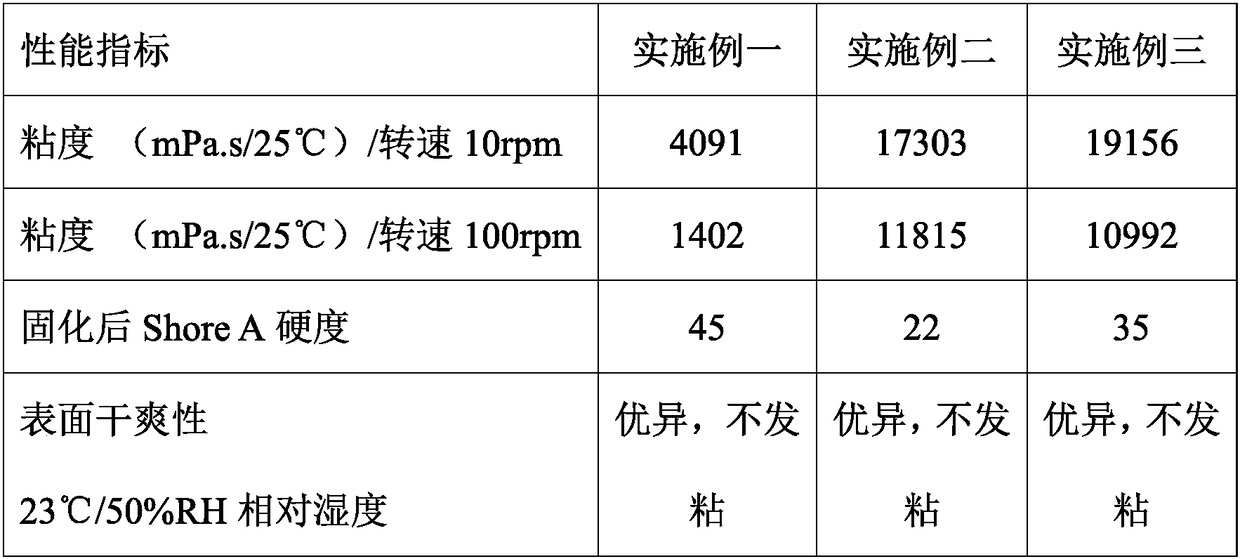

Embodiment 1

[0051] Prepare adhesive composition according to following formula:

[0052] 92.0 parts of hydrogen-containing D4 added to Jiangsu Kexing V-200, and then VCHO (1,2-epoxy-4-vinylcyclohexane) terminated silicone prepolymer;

[0053] 2.0 parts of Aerosil R 106 from Degussa;

[0054] 5.0 parts of Syna Epoxy S-221, 3,3'-[oxybismethylene]bis[3-ethyl]oxetane from Xinaxi Company;

[0055] 0.5 parts of cationic photoinitiator UVI 6992 of Xinaxi Company;

[0056] 0.5 part of CAT 7605E from Japan ShinEtsu Co., bis(4-straight-chain alkyl(C10-C13)phenyl) onium iodide hexafluoroantimonate.

[0057] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0058] Specific preparation method:

[0059] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at 2000-2500 rpm, disperse and mix at high speed for 5 minutes.

Embodiment 2

[0061] Prepare adhesive composition according to following formula:

[0062] 92.0 parts of hydrogen-containing D4 added to Jiangsu Kexing V-1000, and then VCHO (1,2-epoxy-4-vinylcyclohexane)-terminated silicone prepolymer;

[0063] 2.0 parts of Aerosil R 106 from Degussa;

[0064] 5.0 parts of Syna Epoxy S-221, 3,3'-[oxybismethylene]bis[3-ethyl]oxetane from Xinaxi Company;

[0065] 0.5 parts of cationic photoinitiator UVI 6992 of Xinaxi Company;

[0066] 0.5 part of CAT 7605E from Japan ShinEtsu Co., bis(4-straight-chain alkyl(C10-C13)phenyl) onium iodide hexafluoroantimonate.

[0067] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0068] Specific preparation method:

[0069] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at 2000-2500 rpm, disperse and mix at high speed for 5 minutes.

Embodiment 3

[0071] Prepare the adhesive composition according to the following formula, and the preparation process is the same as in Example 1:

[0072] 82.5 parts of hydrogen-containing D4 added to Jiangsu Kexing V-1000, and then VCHO (1,2-epoxy-4-vinylcyclohexane) terminated silicone prepolymer;

[0073] 2.5 parts of Aerosil R 200 from Degussa;

[0074] 5.0 parts of Syna Epoxy S-221, 3,3'-[oxybismethylene]bis[3-ethyl]oxetane from Xinaxi Company;

[0075] 1.0 parts of cationic photoinitiator UVI 6976 of Xinaxi Company;

[0076] 1.0 parts of CAT 7605E, bis(4-straight-chain alkyl(C10-C13)phenyl)hexafluoroantimonate ammonium iodine, from Japan ShinEtsu Company.

[0077] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0078] Specific preparation method:

[0079] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com