Preparation method of rubber modified additive

A rubber modification and additive technology, applied in the field of rubber, can solve the problems of negative impact on other properties of rubber, high cost of carbon black, layering performance, etc., and achieve the effect of improving the effect, improving the dispersion effect, and improving the low temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

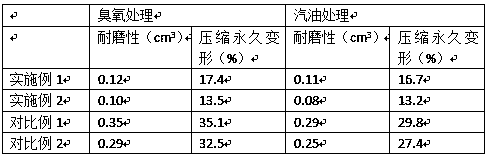

Examples

Embodiment 1

[0019] A preparation method for an additive for rubber modification, comprising the following steps:

[0020] (1) Crush the attapulgite, treat it with a sulfuric acid solution with a mass fraction of 10% for 15-20 minutes, then wash it with water for 2-3 times, then use an ethanol solution with a volume fraction of 60% for 3-4 times, and dry it for later use ;

[0021] (2) Prepare a zinc sulfate solution with a mass fraction of 10%, then add attapulgite treated in step (1) to the solution, stir and mix evenly, use ultrasonic treatment for 38min, and then add attapulgite weight 1% twelve Sodium alkyl sulfonate, stirred for 30min, the weight ratio of zinc sulfate solution and attapulgite is 9:1;

[0022] (3) Continuously add ammonia water dropwise to the solution obtained in step (2), use ultrasonic waves to treat the mixed solution during the dropping process, then evaporate the obtained product to dryness, and treat the residual solid at 140-145°C After 2 hours, the treated ...

Embodiment 2

[0026] A preparation method for an additive for rubber modification, comprising the following steps:

[0027] (1) Crush the attapulgite, treat it with a sulfuric acid solution with a mass fraction of 10% for 15-20 minutes, then wash it with water for 2-3 times, then use an ethanol solution with a volume fraction of 60% for 3-4 times, and dry it. Then use asphalt modification;

[0028] a. To prepare emulsified asphalt, mix the emulsifier with water to prepare an emulsifier aqueous solution with a mass fraction of 5-8%, adjust the Ph to 3-4, then heat to 75°C, heat the asphalt to 170°C, and then spray the asphalt After melting, spray the prepared emulsifier aqueous solution while stirring continuously, the stirring speed is 1500-2000r / min, and then use ultrasonic vibration treatment for 25-30min to obtain emulsified asphalt;

[0029] b. Mix the emulsified asphalt prepared in step a with attapulgite in a weight ratio of 1:15-20, add a silane coupling agent of 1.5% by weight of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com