A chip heat sink, a preparation method thereof, and a DBC substrate assembly

A radiator and chip technology, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of high cost, inability to guarantee the uniformity of fillers, and high implementation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Neither the endpoints nor any values of the ranges disclosed herein are limited to such precise ranges or values, and these ranges or values are understood to include values approaching these ranges or values. For numerical ranges, between the endpoints of each range, between the endpoints of each range and individual point values, and between individual point values can be combined with each other to obtain one or more new numerical ranges, these values Ranges should be considered as specifically disclosed herein.

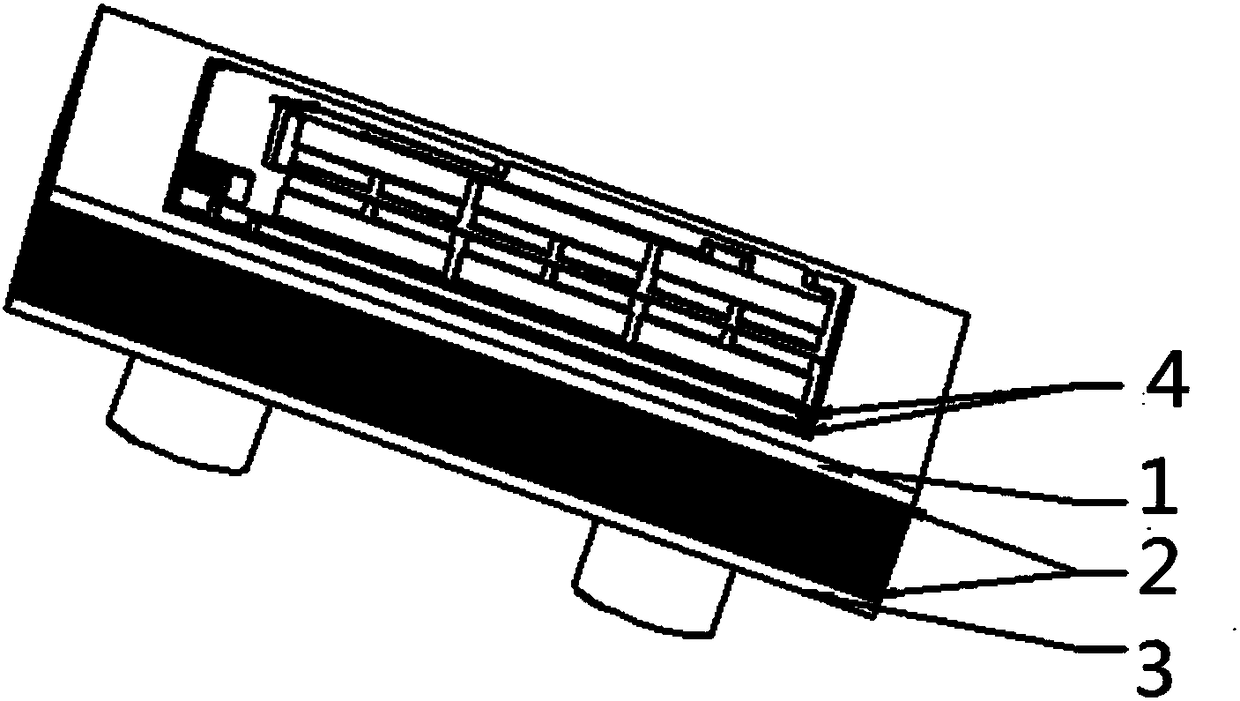

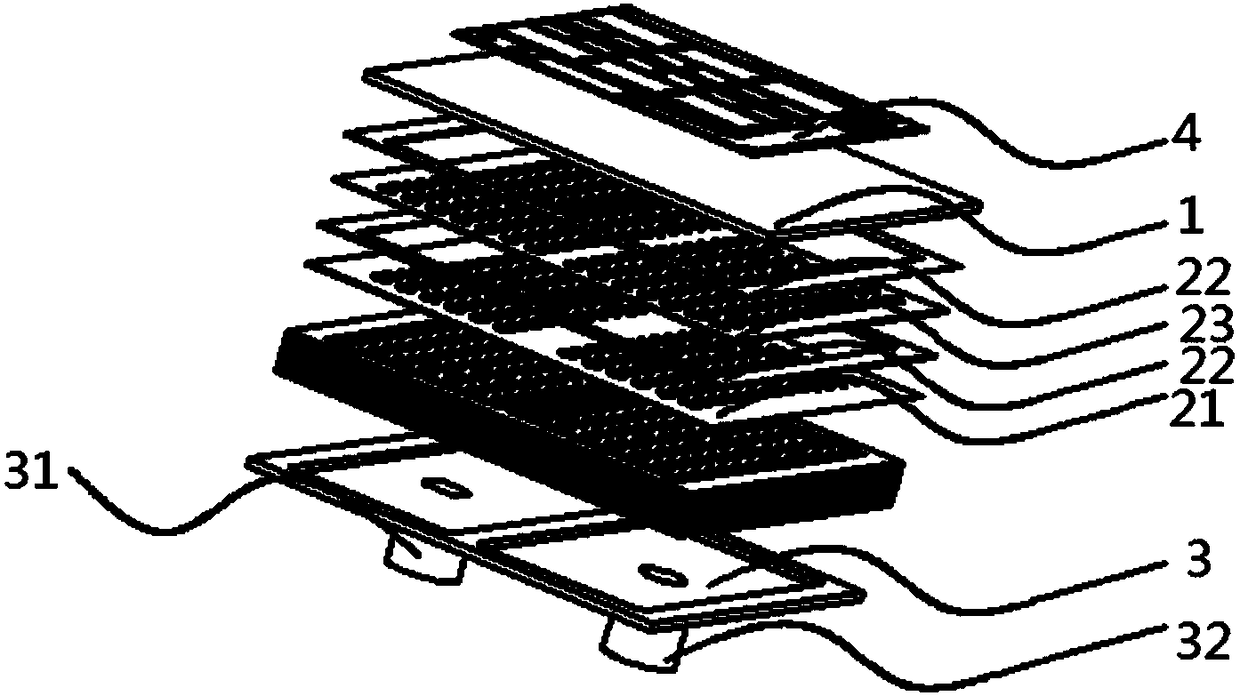

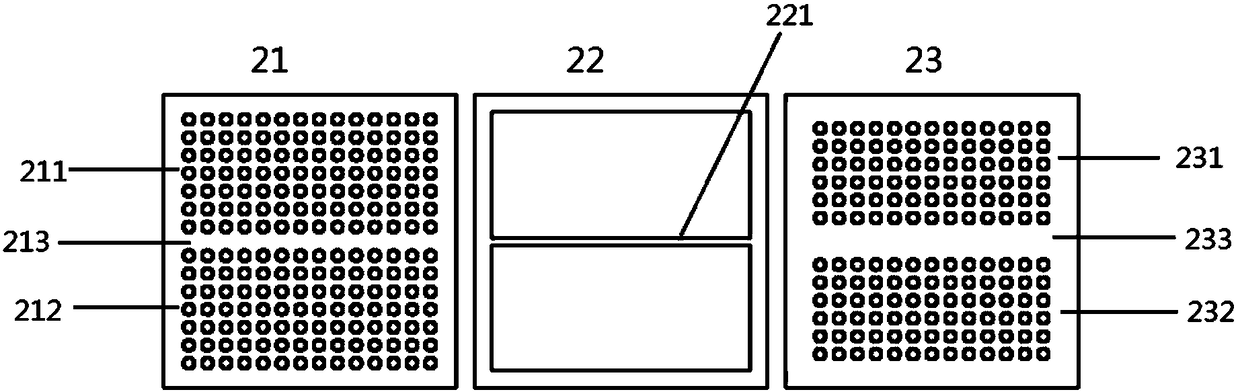

[0058] One aspect of the present invention provides a chip radiator, such as figure 1 and 2 As shown, the chip heat sink includes: an upper end cover 1, a co-fired laminated heat dissipation structure 2 and a lower end cover 3 which are sequentially laminated. The lower end cover 3 is provided with a cooling liquid inlet 31 and a cooling liquid outlet 32. The material of the co-fired laminated heat dissipation structure 2 is oxygen-free copper, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com