Gear-shaped parallel composite elastic fiber and preparation method thereof

A composite elastic fiber and gear-shaped technology, applied in the fiber field, can solve the problems of increasing processing difficulty and increasing cost, and achieve the effect of improving shape retention performance, improving shape retention performance and reducing light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of a gear-shaped side-by-side composite elastic fiber, PBT and PET are melt-spun through a composite spinning assembly to obtain a gear-shaped side-by-side composite elastic fiber, wherein the mass ratio of PBT and PET is 50:50. The pre-PBT chips are dried directly without pre-crystallization, the drying temperature is 130°C, and the drying time is 12h; PET is pre-crystallized at 120°C for 1h, and dried at 165°C for 12h. The process parameters of melt spinning: PET spinning temperature is one zone : 280℃, zone 2: 286℃, zone 3: 292℃, zone 4: 290℃; PBT spinning temperature is zone 1: 250℃, zone 2: 265℃, zone 3: 260℃, zone 4: 260℃ ; The spinning temperature fluctuation is ±1°C, the spinning pressure is 6MPa, the draft ratio is 3 times, and the spinning speed is 2780m / min.

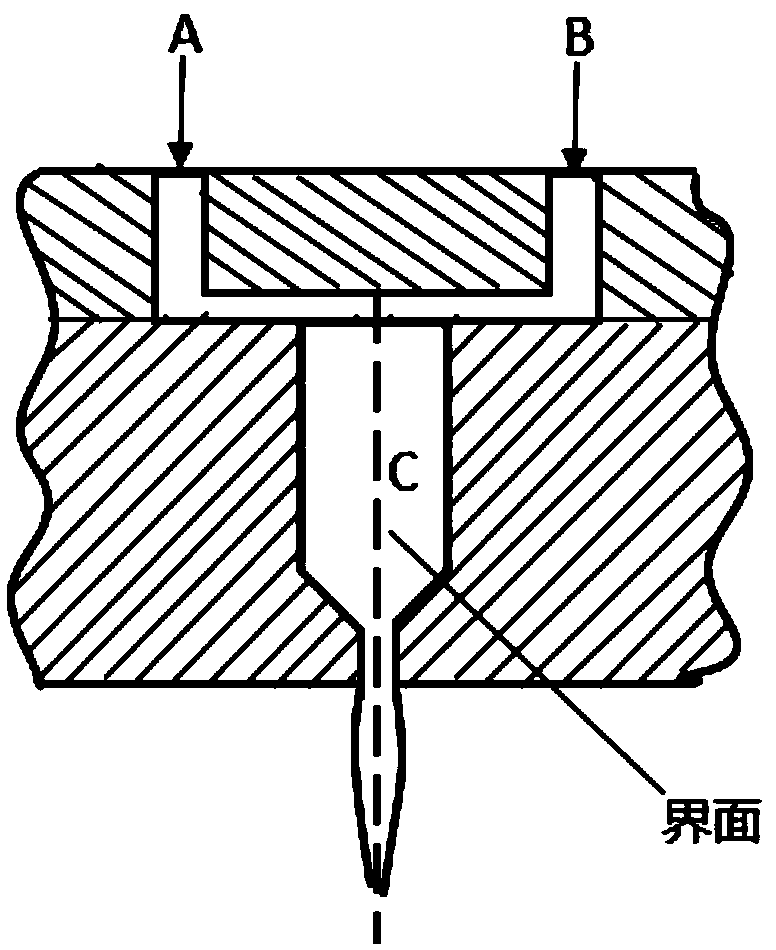

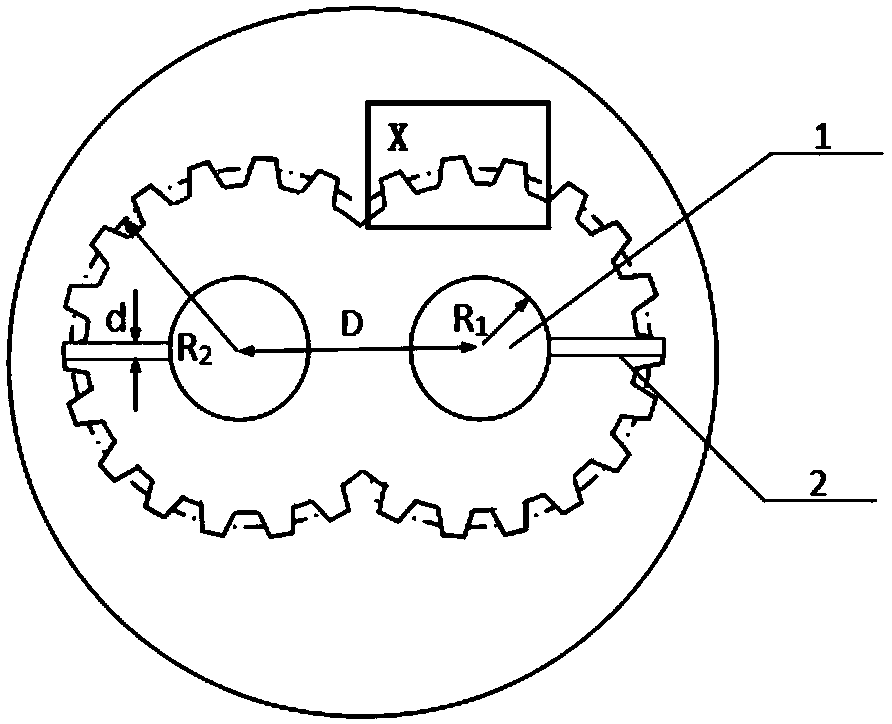

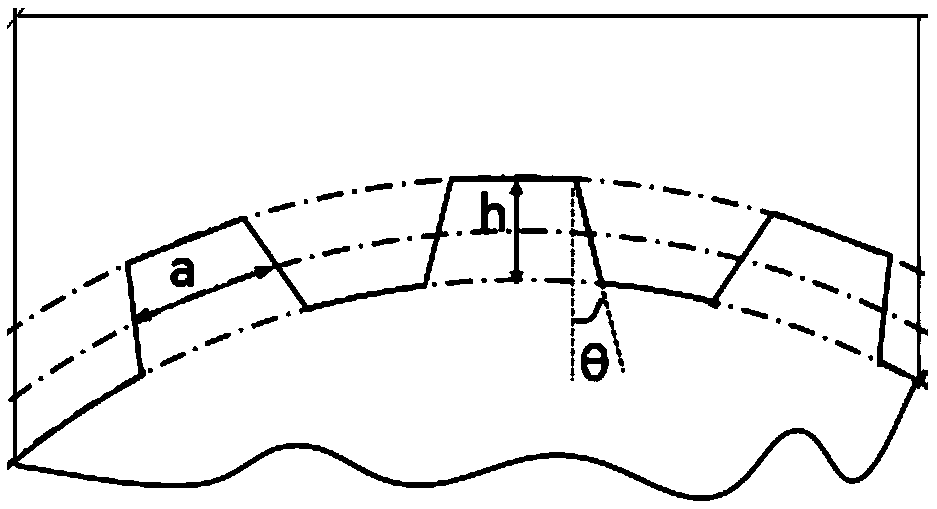

[0044] Composite spinning components such as figure 1 As shown, there are two melt channels (A and B) and a co-extrusion channel C, PBT and PET enter the co-extrusion channel C thr...

Embodiment 2

[0048] A preparation method of a gear-shaped side-by-side composite elastic fiber. TPU and PTT are melt-spun through a composite spinning assembly to obtain a gear-shaped side-by-side composite elastic fiber, wherein the mass ratio of TPU and PTT is 40:60, and TPU and PTT are in Vacuum drying at 120°C for 12 hours before melt spinning, melt spinning process parameters: spinning temperature is 280°C, spinning temperature fluctuation is ±1°C, spinning pressure is 10MPa, draft ratio is 4 times, spinning The speed is 3000m / min.

[0049] Composite spinning assembly and spinneret orifice cross-section are identical with embodiment 1, and difference is that TPU and PTT enter co-extrusion flow channel C through melt channel A and B respectively and extrude from spinneret orifice;

[0050] The crimp shrinkage rate of the final gear-shaped side-by-side composite elastic fiber is 55%, and the elastic recovery rate is 88%; the wrinkle recovery angle of the fabric woven from the fiber is 3...

Embodiment 3

[0052] A preparation method of a gear-shaped side-by-side composite elastic fiber, TPE and polyamide are melt-spun through a composite spinning assembly to obtain a gear-shaped side-by-side composite elastic fiber, wherein the mass ratio of TPE and polyamide is 50:50, TPE and polyamide Polyamide is vacuum dried at 110°C for 7 hours before melt spinning. The process parameters of melt spinning are: spinning temperature is 250°C, spinning temperature fluctuation is ±1°C, spinning pressure is 15MPa, and draft ratio is 3 times , The spinning speed is 3500m / min.

[0053] The cross section of the composite spinning assembly and the spinneret orifice is the same as in Example 1, except that TPE and polyamide enter the co-extrusion flow channel C through the melt channels A and B respectively and then extrude from the spinneret orifice;

[0054] The crimp shrinkage rate of the finally prepared gear-shaped side-by-side composite elastic fiber is 52%, and the elastic recovery rate is 82...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com