Carbon fiber prepreg and preparation method thereof

A technology of carbon fiber prepreg and prepreg, applied in flat products, other household appliances, applications, etc., can solve the problems of impact resistance and low interlayer toughness, achieve interlayer toughness, improve performance, and excellent impact resistance sexual effect

Inactive Publication Date: 2019-01-15

四川鑫达企业集团有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem of low impact resistance and interlayer toughness of resin matrix carbon fiber prepreg, to provide a kind of prepreg capable of making impact resistance and high interlayer toughness polymer composite material and its preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

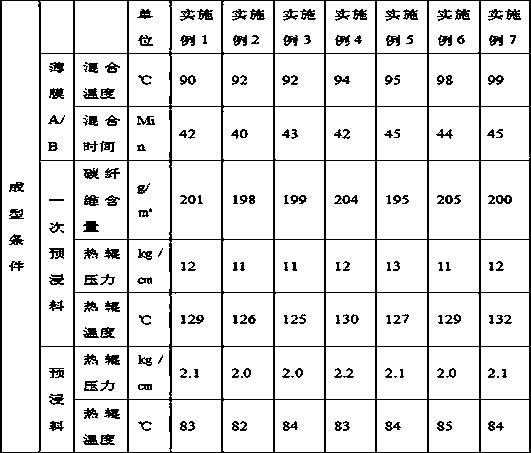

[0012] Table I

[0013]

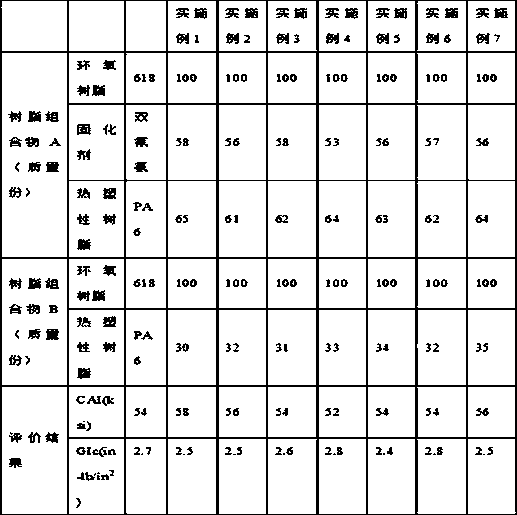

[0014] Table II

[0015]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a carbon fiber prepreg and a preparation method thereof, and epoxy resin serves as the matrix of the carbon fiber prepreg. The carbon fiber prepreg is formed in two steps that primary prepreg comprises a reinforcing fiber matrix and an epoxy resin composite which is composed of epoxy resin, thermoplastic resin and a curing agent, and a reinforcing fiber layer is immersed into the epoxy resin composite; and multilayer compression molding is conducted on the formed primary prepreg and an epoxy resin soluble thermoplastic resin composite which contains epoxy resin and dissolves in epoxy resin through a hot rolling method, and finally the prepreg meeting performance requirements is prepared and obtained. Through the carbon fiber prepreg obtained through multilayer compression molding, impact resistance and interlaminar toughness of the resin-matrix carbon fiber prepreg can be improved significantly.

Description

technical field [0001] The patent of the present invention mainly relates to carbon fiber prepreg with epoxy resin as the matrix and its preparation method, and the obtained carbon fiber prepreg is mainly used as reinforcement of composite materials. Because it adopts the production process of multi-layer hot roller pressing, the finished product can significantly improve the performance of the thermosetting resin matrix carbon fiber prepreg in terms of impact resistance and interlayer toughness. Background technique [0002] Carbon fiber and its composite materials are known as the "black gold" of the 21st century because of their excellent comprehensive performance and high added value. In practical applications, carbon fiber is often used as reinforcing fiber, and composite materials reinforced by carbon fiber usually have the characteristics of high strength, high rigidity and light weight, so they are widely used in modern industries, such as aerospace, automobile, ship...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29B15/10B29C70/50B29C41/24B29K63/00B29K105/08B29L7/00B29K77/00B29K61/20

CPCB29B15/10B29C41/24B29C70/504B29K2061/20B29K2063/00B29K2077/00B29K2105/0872B29L2007/00

Inventor 张银坤马俊杰

Owner 四川鑫达企业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com