Chemical nickel plating solution and chemical nickel plating method suitable for high-volume fraction SiCp/Al composite material

A technology of electroless nickel plating and composite materials, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of affecting the quality of plating, increasing production costs, and limited service life of the solution, achieving excellent stability Performance, guaranteed high quality, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

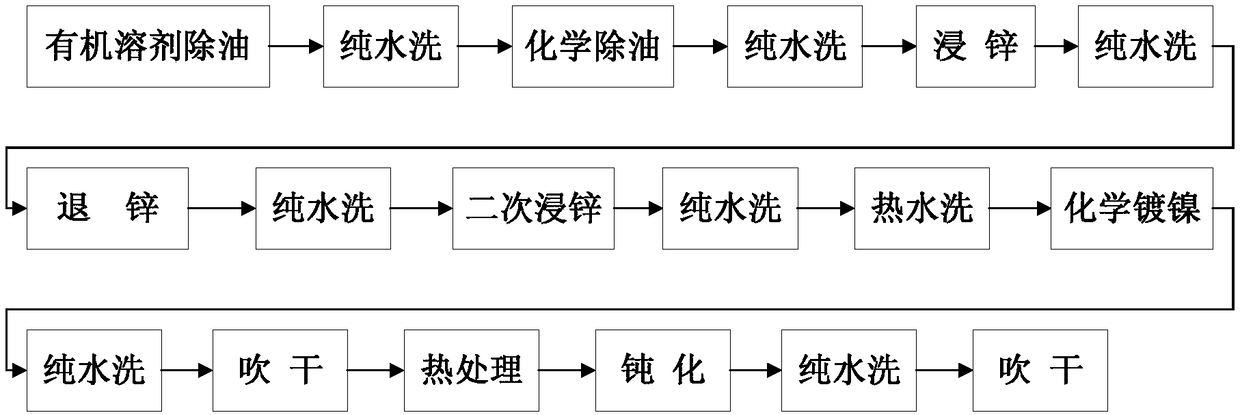

Method used

Image

Examples

Embodiment

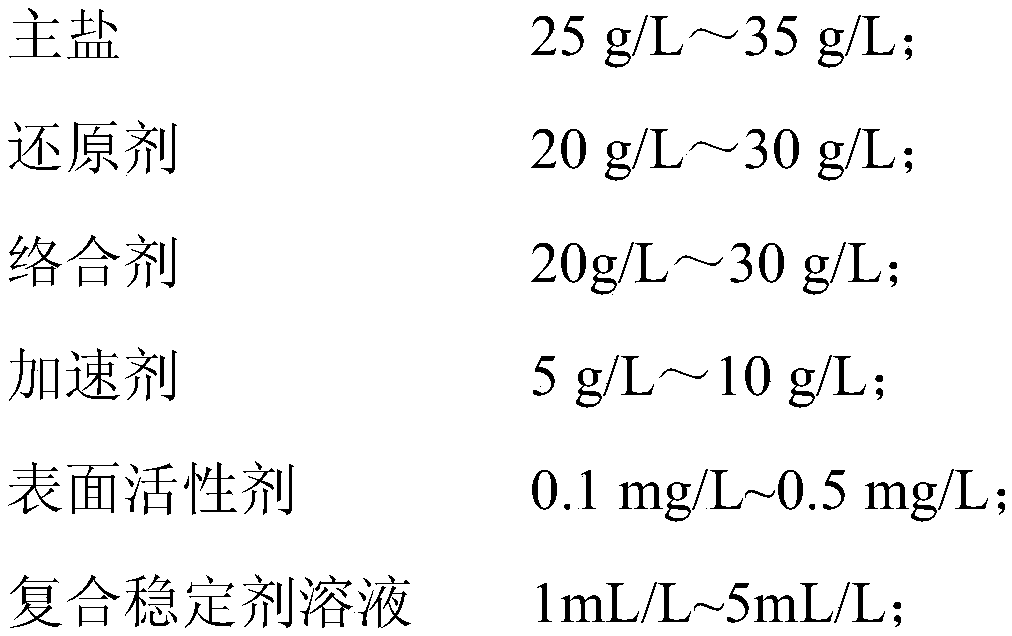

[0070] Table 1 shows the formulation of the high-volume SiCp / Al composite high-stability electroless nickel plating solution.

[0071]

[0072] The mass concentration of potassium iodate, potassium nitrate, fumaric acid or thiourea in the above table is the mass concentration of the compound stabilizer solution prepared, wherein formula 1, formula 2, formula 3, formula 4, formula 5, The volumes of the compound stabilizer solutions added in formula 6 are 3mL, 5mL, 1mL, 2mL, 4mL, 1mL respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com