Emulsion type silicone modified castor oil polyether defoamer and preparation method thereof

A technology of polyether defoamer and castor oil, which is applied in the field of emulsion-type silicone modified castor oil polyether defoamer and its preparation, which can solve the difficulties of polyether preparation, the reduction of defoaming performance, the oxidation of polyether chains, etc. problems, to achieve the effect of strong anti-foaming ability, fast defoaming speed and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

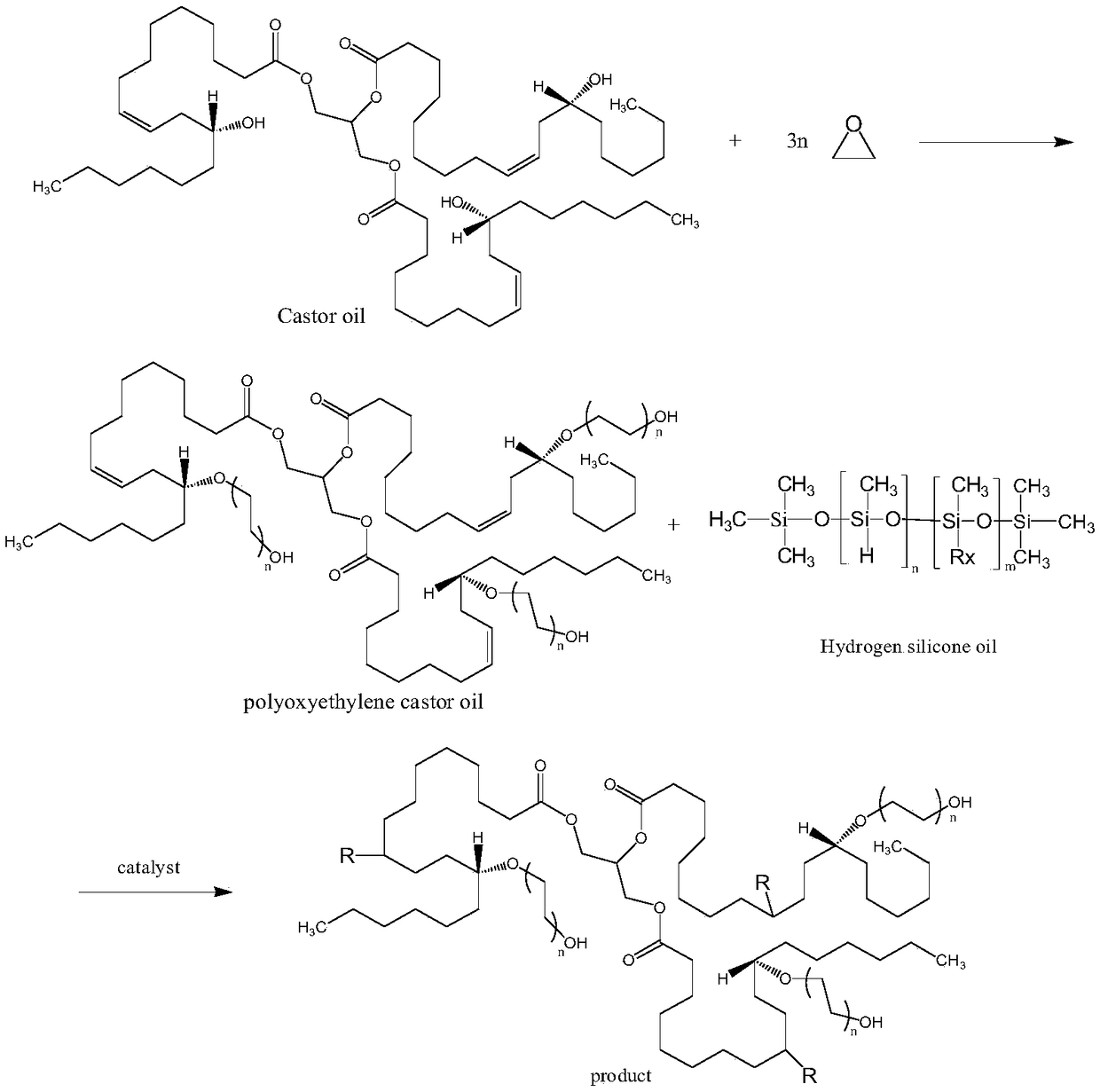

[0031] The preparation method of emulsion type organosilicon modified castor oil polyether defoamer of the present invention comprises the steps:

[0032] 1) Put the castor oil in the autoclave, add 0.05%-0.3% basic catalyst (one or more of KOH, sodium methylate, potassium methylate or alkyllithium, calculated according to the quality of castor oil), stir Raise the temperature to 105-120°C, and evacuate to ≤-0.095MPa, rise to the set 120-160°C, and the reaction time is 2-5h. After the reaction, the degassing negative pressure is ≤-0.075MPa, stop vacuuming, and feed Epoxy compounds with a molar ratio of 1:20-80 to castor oil (one or two mixtures of ethylene oxide and propylene oxide, the amount added is 20-80 epoxy groups based on the number of epoxy groups) base), and heated up to react for a certain period of time, and degassed under negative pressure after the reaction was completed to obtain castor oil polyether;

[0033] 2) Put castor oil polyether with a molar ratio of 1...

Embodiment 1

[0041] Put castor oil in a 2.5L autoclave, add 0.15% KOH (calculated by the mass of castor oil), stir and heat up, and vacuumize, rise to 110 ° C, stop vacuuming, feed and castor oil molar ratio is 1 : Ethylene oxide at 60°C and heated up to 130°C for 3 hours, degassing under negative pressure after the reaction was completed, and the vacuum degree was -0.09MPa to obtain castor oil polyether;

[0042] Put castor oil polyether with a molar ratio of 1:2 and 0.1% hydrogen-containing silicone oil with a hydrogen content of 0.25% in a reactor, and stir for 40 minutes at a pressure of -0.09MPa and a temperature of 80°C for water removal treatment , followed by adding 0.3% chloroplatinic acid catalyst, setting nitrogen, raising the temperature to 90° C. for 4 hours in a nitrogen protection system, and finally obtaining the silicone-modified castor oil polyether defoamer active substance;

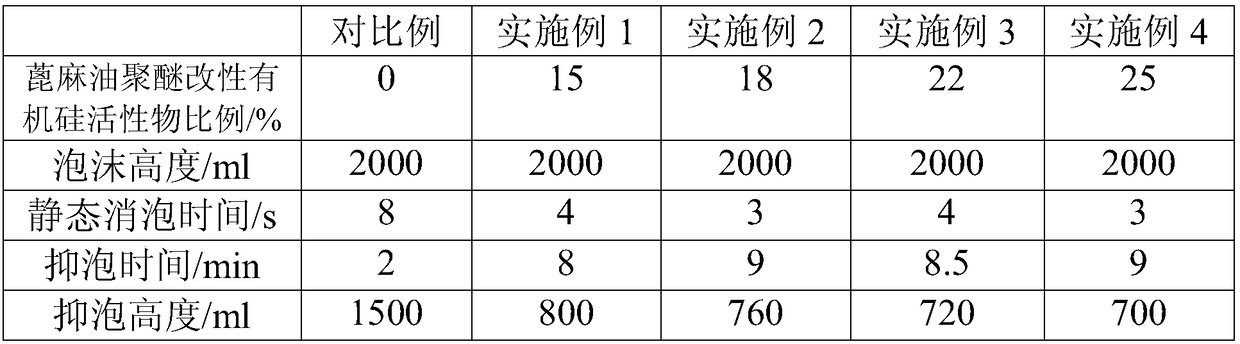

[0043] Take 15g of silicone-modified castor oil polyether antifoaming agent active substance, 2...

Embodiment 2

[0045] Castor oil is placed in 2.5L autoclave, adds 0.05% sodium methylate (calculated by castor oil quality), stirs and heats up, and vacuumizes, rises to 105 ℃, stops vacuuming, feeds and castor oil mol ratio is 1:80 propylene oxide and heated up to 120°C to react for a certain period of time. After the reaction was completed, negative pressure degassed and the vacuum degree was -0.09MPa to obtain castor oil polyether;

[0046] Put castor oil polyether with a molar ratio of 1:3 and 0.36% hydrogen-containing silicone oil in the reactor, stir at a pressure of -0.09MPa and a temperature of 85°C for 30 minutes to remove water, and then add 0.5% chlorine Platinic acid catalyst, nitrogen, in a nitrogen protection system, the temperature was raised to 85 ° C for 6 hours, and finally the silicone modified castor oil polyether defoamer active material was obtained;

[0047] Take 18g of silicone-modified castor oil polyether antifoaming agent active substance, 2g of Tween 20, 15g of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com