A manufacture method of high-frequency microwave board and high-density interconnect board

A technology of high-density interconnection board and manufacturing method, which is applied in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, electrical components, etc., can solve problems such as uneven ink thickness, and achieve low defect rate and flatness Good, fine line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a high-density interconnection board manufacturing method for high-frequency microwave boards, including the following steps:

[0040] (1) Cutting: use a shearing machine to cut the substrate according to the size of the cut, cut the cut sheet and grind the edges. process; among them, the cutting size is 0.762mm in substrate thickness and 1 / 1OZ in copper thickness.

[0041](2) Drilling: use a new drill bit, produce according to the drilling parameters, drill the sheet metal to form a through hole, and use manual grinding on the front after drilling; specifically, the drilling parameters are: when drilling a 0.8mm hole , the feeding speed is 1.6m / min, the retracting speed is 10m / min, and the rotating speed is 60krpm; when drilling a 1.0mm hole, the feeding speed is 1.2m / min, the retracting speed is 10m / min, and the rotating speed is 50krpm; For a 1.3mm hole, the feed speed is 1.0m / min, the retract speed is 10m / min, and the rotation speed is 40kr...

Embodiment 2

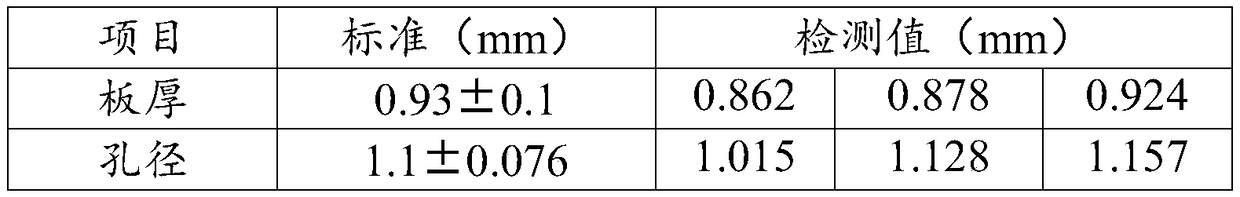

[0057] Quality data testing: Three batches of high-frequency microwave boards and high-density interconnection boards produced according to the preparation method of Example 1 were tested for finished board thickness, finished product aperture, solderability, and thermal stress. The specific test results are shown in the table 1-3.

[0058] Table 1. Test results of finished plate thickness and hole diameter

[0059]

[0060] It can be seen from Table 1 that the high-density interconnection board prepared by the present invention meets the standard requirements in parameters such as board thickness and hole diameter.

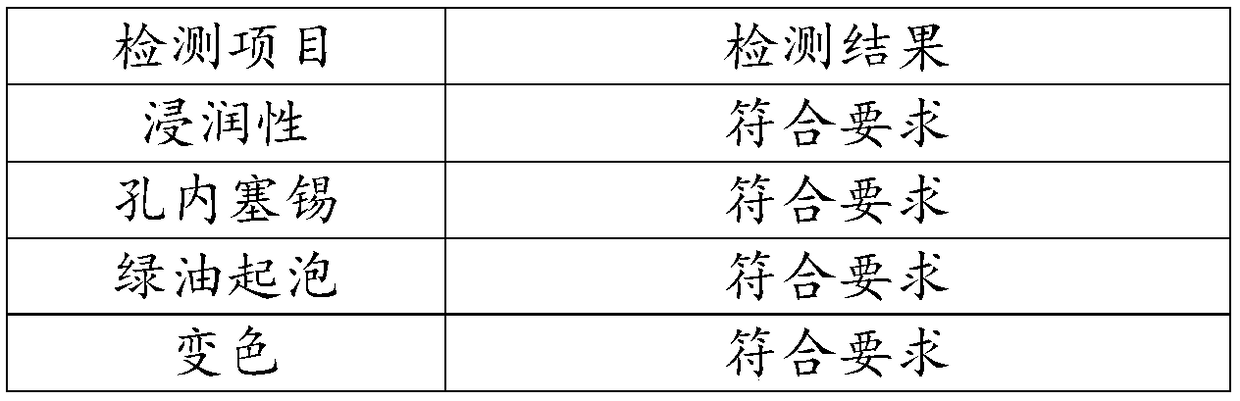

[0061] Table 2. Solderability test results

[0062]

[0063]

[0064] Among them, the test method adopts the IPC-TM-650 standard, the detection equipment adopts a tin furnace, the test temperature is 260±5°C, and the test time is 1h.

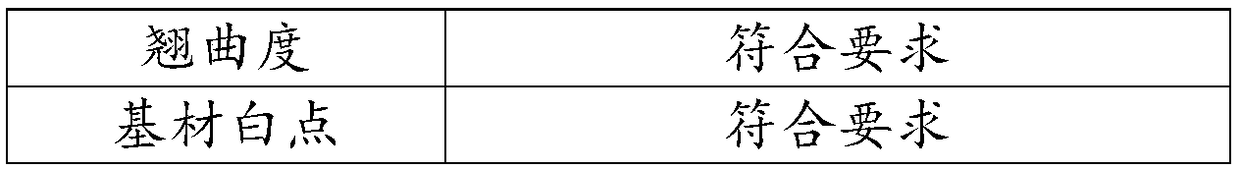

[0065] Table 3. Thermal stress test results

[0066] Test items

[0067] Among them, the test method adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com