A method for prepare a low moisture ceramic separator for lithium battery, an aqueous slurry, and a ceramic separator

A technology of ceramic diaphragm and water-based slurry, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems affecting the electrical performance and safety performance of lithium batteries, and ceramic drop points, etc., to achieve low water absorption performance and not easy to drop Powder, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

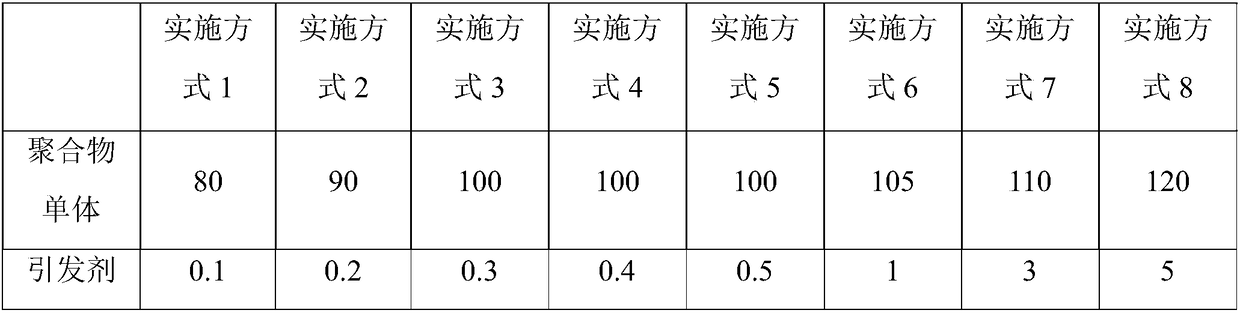

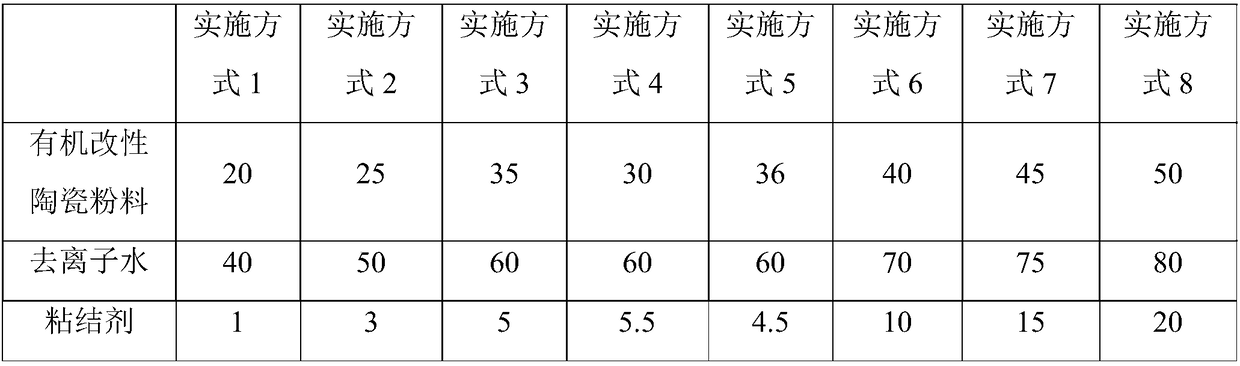

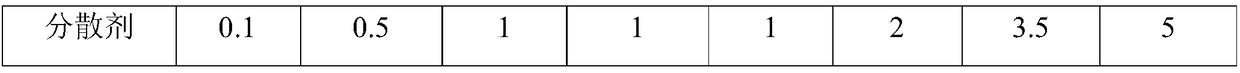

Embodiment 1

[0027] Bake 6kg of aluminum oxide powder at 80°C for 24 hours, then add it to 10kg of methyl methacrylate (MMA) monomer, add 30g of benzoyl peroxide (BPO), and impregnate it under normal temperature and pressure After 4 days, take it out and react at 80°C for 1 hour, and finally dry it in a vacuum oven at 40°C for 24 hours to make an organically modified ceramic powder. Stir the above-mentioned organically modified ceramic powder, deionized water, polymethyl methacrylate binder, sodium carboxymethyl cellulose, and sodium polyacrylate according to the ingredients of 30:60:5:0.5:0.5, and sand the The milling time is 1 hour, the rotation speed is 1000 RPM, and the aqueous slurry is obtained. The above water-based slurry was coated on one side of the 14um PP separator by micro-gravure roll coating, and baked at 65°C for 2 minutes to obtain a ceramic separator with a total thickness of 16um.

Embodiment 2

[0029] Bake 6kg of aluminum oxide powder at 80°C for 24h, then add it to 10kg of propyl acrylate monomer, add 30g of azobisisobutylcyanide (AIBN), impregnate it at normal temperature and pressure for 5 days, and then Take it out and react at 70°C for 1.5h, and finally dry it in a vacuum oven at 40°C for 24h to prepare an organically modified ceramic powder. Stir the above-mentioned organically modified ceramic powder, deionized water, polymethyl methacrylate binder, sodium carboxymethyl cellulose, and sodium polyacrylate according to the ingredients of 30:60:5.5:0.5:0.5, and sand the The milling time is 1.5 hours, the rotation speed is 800 RPM, and the aqueous slurry is obtained. The above water-based slurry was coated on one side of the 14um PP separator by micro-gravure roll coating, and baked at 70°C for 2 minutes to obtain a ceramic separator with a total thickness of 16um.

Embodiment 3

[0031] Bake 6kg of aluminum oxide powder at 80°C for 24 hours, then add it to 10kg of styrene monomer, add 40g of azobisisobutylcyanide (AIBN), impregnate it for 5 days at normal temperature and pressure, and then take it out And react at 80° C. for 1.5 hours, and finally dry in a vacuum oven at 40° C. for 24 hours to prepare an organically modified ceramic powder. The above-mentioned organically modified ceramic powder, deionized water, styrene-acrylic emulsion binder, sodium carboxymethyl cellulose, and ammonium polyacrylate are stirred according to the ingredients of 36:60:4.5:0.5:0.5, and the sanding time of the sand mill is 2 hours, rotating speed 600RPM, obtain water-based slurry. The above water-based slurry was coated on one side of the 14um PP separator by micro-gravure roll coating, and baked at 65°C for 2 minutes to obtain a ceramic separator with a total thickness of 16um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com