High-modulus magnesium alloy and preparation method thereof

A magnesium alloy, high modulus technology, applied in the field of metal materials, can solve the problems of unsatisfactory engineering fields and low elastic modulus of magnesium alloys, and achieve good mechanical properties, high modulus, and large-scale industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

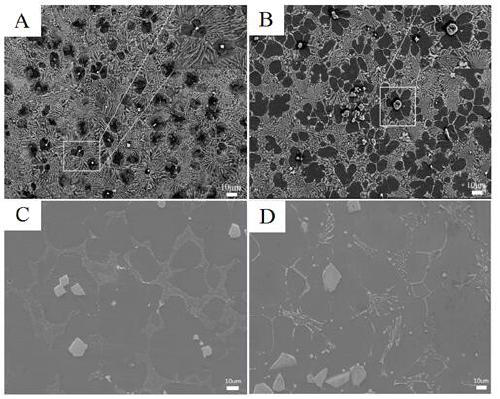

Image

Examples

Embodiment 1

[0025] The magnesium alloy used included the following components in weight percentage: 15.5 wt.%Y, 1.8 wt.%Ni, 6 wt.%Al, 4wt.%Li, 0.4 wt.%Zr, the balance being Mg and unavoidable Impurities, the total amount of impurities is less than 0.12 wt.%.

[0026] 1) Use industrial pure magnesium ingots, pure nickel blocks, pure aluminum sheets, pure lithium, Mg-30%Y master alloys, and Mg-30%Zr master alloys as raw materials to calculate the ingredients; Vacuum melting in the electromagnetic induction furnace, the vacuum degree is 1.8~1.9×10 -2 KPa, first keep warm at 5KW for 2min, then rise to 15KW and keep warm for 10min, after it is completely melted, place it in brine to cool down to get magnesium alloy ingot;

[0027] 2) Put the as-cast Mg-Y-Ni-Al-Li-Zr magnesium alloy in a heat treatment furnace for high-temperature homogenization treatment at a heating rate of 15~20°C / min, heat to 500°C, and keep it for 12 hours. The ingot is water-cooled to room temperature;

[0028] 3) Mach...

Embodiment 2

[0031] The magnesium alloy used includes the following components in weight percentage: 8 wt.%Y, 6 wt.%Al, 4 wt.%Li, 0.4 wt.%Zr, the balance is Mg and unavoidable impurities, the total amount of impurities Less than 0.12 wt.%.

[0032] 1) Use industrial pure magnesium ingots, pure nickel blocks, pure aluminum sheets, pure lithium, Mg-30%Y master alloys, and Mg-30%Zr master alloys as raw materials to calculate the ingredients; Vacuum melting in the electromagnetic induction furnace, the vacuum degree is 1.8~1.9×10 -2 KPa, first keep warm at 5KW for 2min, then rise to 15KW and keep warm for 10min, after it is completely melted, place it in brine to cool down to get magnesium alloy ingot;

[0033] 2) Put the as-cast Mg-Y-Ni-Al-Li-Zr magnesium alloy in a heat treatment furnace for high-temperature homogenization treatment at a heating rate of 15~20°C / min, heat to 500°C, and keep it for 12 hours. The ingot is water-cooled to room temperature;

[0034] 3) Machining the magnesium ...

Embodiment 3

[0037] The magnesium alloy used includes the following components in weight percentage: 12.0 wt.%Gd, 1.0 wt.%Zn, 0.5 wt.%Zr, 0.5 wt.%Ag, 4 wt.%Al, 3 wt.%Li, and The amount is Mg and unavoidable impurities, the total amount of impurities is less than 0.12 wt.%.

[0038] 1) Calculate the ingredients with industrial pure magnesium ingots, pure aluminum flakes, pure zinc, pure silver, pure lithium, Mg-30% Gd master alloy, and Mg-30% Zr master alloy; Vacuum smelting in an electromagnetic induction furnace with gas protection, the vacuum degree is 1.8~1.9×10 -2 KPa, first keep warm at 6KW for 2 minutes, then rise to 15KW and keep warm for 10 minutes, after it is completely melted, place it in salt water to cool down to obtain a magnesium alloy ingot;

[0039] 2) Put the as-cast Mg-Gd-Al-Li-Ag-Zr-Zn magnesium alloy in a heat treatment furnace for high-temperature homogenization treatment at a heating rate of 15~20°C / min, heat to 520°C, and hold for 14 hours to complete Finally, the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com