Polyvinyl chloride wood-plastic flame retardance composite plate and preparation method

A technology of flame-retardant composite and polyvinyl chloride, which is applied in the field of wood-plastic materials, can solve the problems of low strength, low hardness, imperfect performance, and low impact strength, and achieve good antibacterial effect, non-deformation, and strong impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

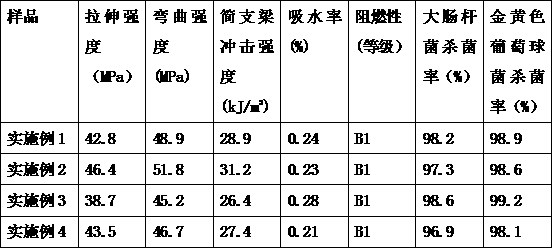

Examples

Embodiment 1

[0029] A polyvinyl chloride wood-plastic flame-retardant composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 90 parts of bamboo powder, 12 parts of shell powder, 25 parts of nano-calcium carbonate, 6 parts of aramid fiber, and sepiolite 5 parts of fiber, 1.5 parts of foaming agent, 1 part of plasticizer, 2 parts of coupling agent, 1.5 parts of compound antibacterial agent, 1 part of flame retardant, 2 parts of stabilizer, 1 part of methallyl polyoxyethylene ether , 0.5 parts of octaphenyl clathrate silsesquioxane, 2 parts of phytic acid and 1 part of nonylphenol polyoxyethylene ether.

[0030] The foaming agent consists of ammonium bicarbonate, triterpene saponin and isooctyl alcohol polyoxyethylene ether phosphate in a weight ratio of 2:1:2.

[0031] The plasticizer is composed of diphenyl-octyl phosphate and castor oil polyoxyethylene ether in a weight ratio of 2:1.

[0032] The coupling agent is composed of sodium lignosulfon...

Embodiment 2

[0042] A polyvinyl chloride wood-plastic flame-retardant composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 100 parts of bamboo powder, 8 parts of shell powder, 20 parts of nano-calcium carbonate, 8 parts of aramid fiber, and sepiolite 3 parts of fiber, 2.5 parts of foaming agent, 1.5 parts of plasticizer, 2.5 parts of coupling agent, 1 part of compound antibacterial agent, 1.5 parts of flame retardant, 1.5 parts of stabilizer, 1.5 parts of methallyl polyoxyethylene ether , 1 part of octaphenyl clathrate silsesquioxane, 3 parts of phytic acid and 0.5 part of nonylphenol polyoxyethylene ether.

[0043] The foaming agent consists of ammonium bicarbonate, triterpene saponin and isooctyl alcohol polyoxyethylene ether phosphate in a weight ratio of 1:1:3.

[0044] The plasticizer is composed of diphenyl-octyl phosphate and castor oil polyoxyethylene ether in a weight ratio of 3:1.

[0045] The coupling agent is composed of sodium li...

Embodiment 3

[0055] A polyvinyl chloride wood-plastic flame-retardant composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 80 parts of bamboo powder, 5 parts of shell powder, 30 parts of nano-calcium carbonate, 8 parts of aramid fiber, sepiolite 5 parts of fiber, 1 part of foaming agent, 2 parts of plasticizer, 3 parts of coupling agent, 1.5 parts of compound antibacterial agent, 1 part of flame retardant, 2.5 parts of stabilizer, 0.8 part of methallyl polyoxyethylene ether , 1.2 parts of octaphenyl clathrate silsesquioxane, 2 parts of phytic acid and 1 part of nonylphenol polyoxyethylene ether.

[0056] The foaming agent consists of ammonium bicarbonate, triterpene saponin and isooctyl alcohol polyoxyethylene ether phosphate in a weight ratio of 2:1:2.

[0057] The plasticizer is composed of diphenyl octyl phosphate and castor oil polyoxyethylene ether in a weight ratio of 1:1.

[0058] The coupling agent is composed of sodium lignosulfonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com