Preparation method of hydrogenation catalyst carrier

A catalyst carrier and hydrotreating technology, applied in catalyst carriers, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost, complicated preparation process, increase production cost, etc., and achieve low production cost, carrier Excellent performance and efficient connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

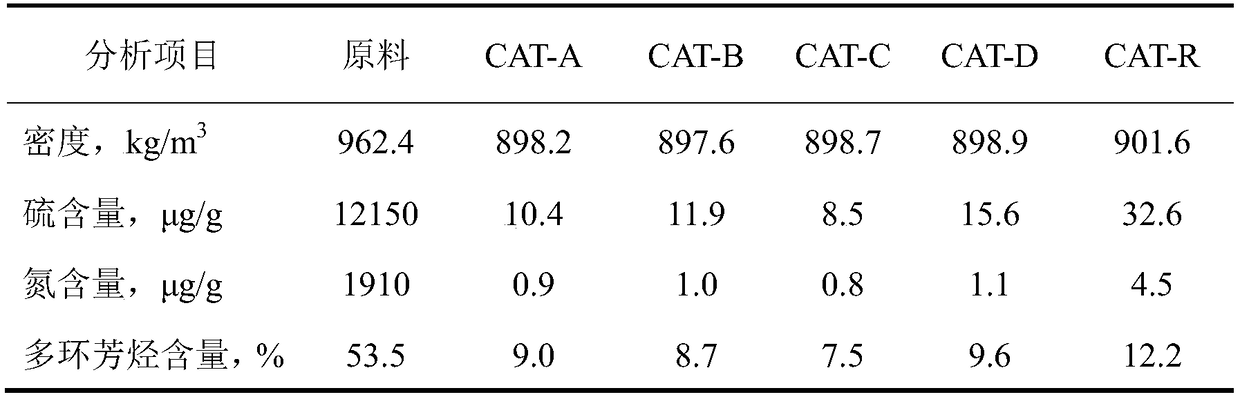

Examples

Embodiment 1

[0022] Take 600g of the pseudo-boehmite sol precursor and put it into the hopper of the kneader, add 16g of high-viscosity aluminum hydroxide dry rubber powder and knead evenly, add 16g of nano-silica, 12g of ammonium dihydrogen phosphate, 9g of citric acid, polyethylene glycol (PEG5000) 6g Continue kneading for 60 minutes until the color of the material becomes darker, and kneading can form a ball. Take the material out and extrude it in the extruder, and the appearance is a clover-shaped strip.

[0023] After the formed strips were cured at room temperature for 12 hours, they were dried at 120°C for 6 hours and calcined at 550°C for 3 hours to obtain a finished carrier, numbered ZT-A. The physical properties of the carrier are shown in Table 1.

Embodiment 2

[0025] Take 600g of the pseudo-boehmite sol precursor and put it into the hopper of the kneader, add 35g of high-viscosity aluminum hydroxide dry rubber powder and knead evenly, add 16g of titanium dioxide, 9g of oxalic acid, and 6g of soluble starch and continue kneading for 55min until the color of the material becomes darker. It can be kneaded into a ball, and the material is taken out and extruded in the extruder to form a butterfly-shaped strip.

[0026] After the formed strips were cured at room temperature for 12 hours, they were dried at 120°C for 6 hours and calcined at 550°C for 3 hours to obtain a finished carrier, numbered ZT-B. The physical properties of the carrier are shown in Table 1.

Embodiment 3

[0028] Take 600g of the pseudoboehmite sol precursor and put it into the kneader hopper, add 22g of high-viscosity aluminum hydroxide dry rubber powder and knead evenly, add 22g of zirconium oxynitrate, 21g of silica sol, 9g of tartaric acid, and 6g of polyethylene glycol (PEG10000) Continue kneading for 45 minutes, until the color of the material becomes darker, kneading can form a ball, take out the material and shape it in the tooth ball machine, and the appearance is a five-tooth ball shape.

[0029] The formed pellets were cured at room temperature for 12 hours, dried at 120°C for 4 hours, and calcined at 550°C for 3 hours to obtain the finished carrier ZT-C. The physical properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com