EGCG (epigallocatechin gallate) and ganoderma lucidum spore oil containing soft capsule and preparation method thereof

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spores, which can be used in capsule delivery, pharmaceutical formulations, oil/fat/wax non-effective ingredients, etc. It can solve the problems of pepsin damage, low bioavailability, and large molecular volume that is difficult to absorb. High bioavailability, simple production process, and increased antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

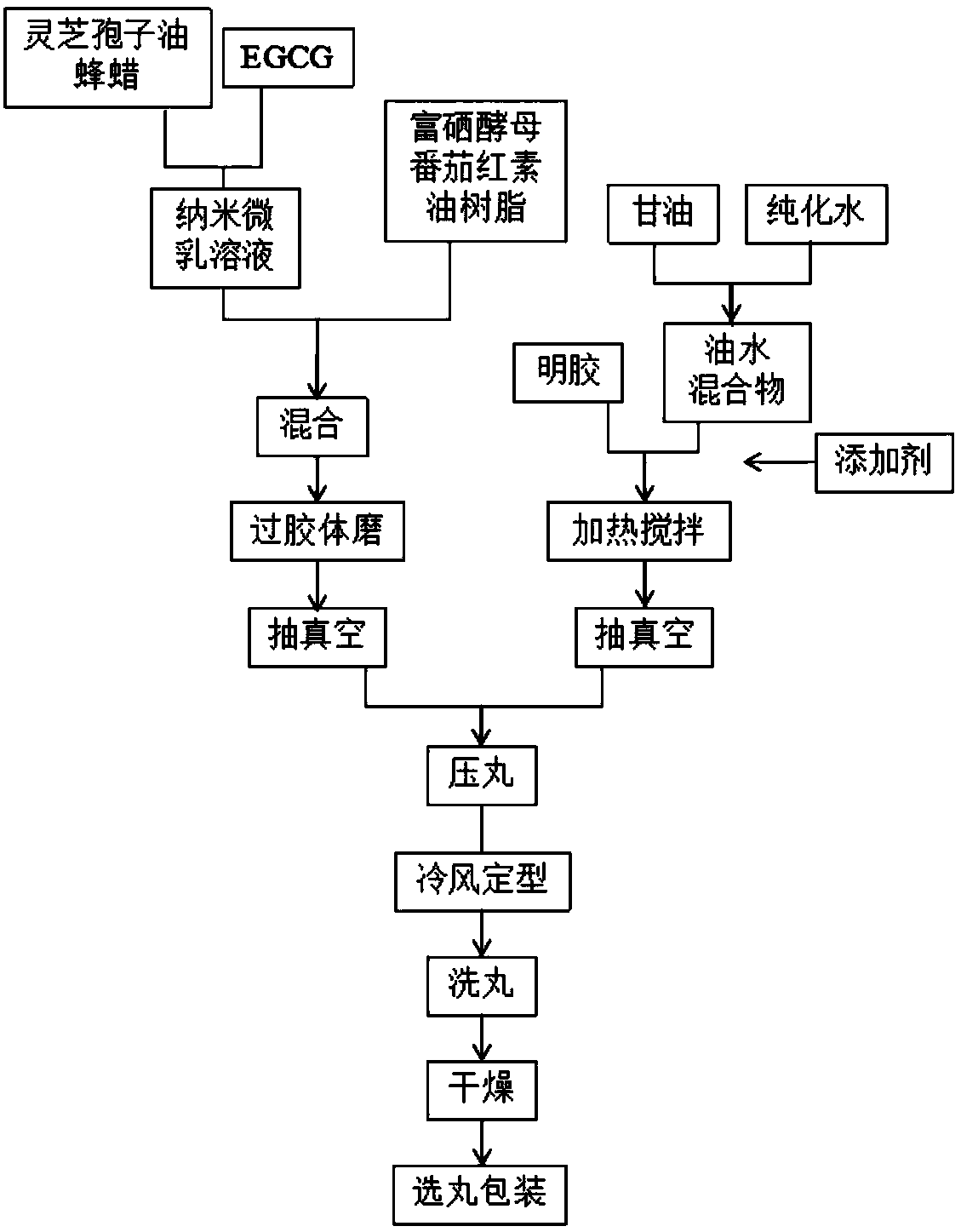

[0030] The preparation method of the EGCG Ganoderma lucidum spore oil soft capsule of the present invention includes the following steps:

[0031] Step 1. Take the Ganoderma lucidum spore oil and beeswax and mix them according to the ratio. After heating and stirring for a period of time, the mixture is placed in an ultrasonic instrument and sonicated. During this process, the EGCG solution is slowly injected into the mixture, and the mixed solution changes from turbidity. To clarify, prepare a nano-microemulsion solution embedded with EGCG;

[0032] Step 2: Add selenium-enriched yeast and lycopene oleoresin to the microemulsion solution, stir and mix evenly, grind in a colloid mill, and then vacuum and degas to obtain a content material liquid;

[0033] Step 3: Add glycerin to purified water, mix and heat, then add gelatin, titanium dioxide and caramel pigment and heat preservation and stir. After the mixture is uniformly dissolved and mixed, it is filtered, vacuumed and degassed to...

Embodiment 1

[0045] The preparation method of the EGCG Ganoderma lucidum spore oil soft capsule of the present invention includes the following steps:

[0046] Step 1. Mix 10g of beeswax with 154g of Ganoderma lucidum spore oil, heat to 65℃ to melt, stir at 300rpm / min for 20min to make it evenly mixed, place the mixture in an ultrasonic instrument under 100Hz ultrasonic vibration for 30min, the concentration will be 100mL of 0.15g / mL EGCG solution was slowly injected into the mixture, and after the mixed solution changed from turbidity to clear, a nano-microemulsion solution embedded with EGCG was prepared;

[0047] Step 2: Add 3g selenium-enriched yeast (2g / L) and 18g lycopene oleoresin (containing 10% lycopene) to the microemulsion solution, stir and mix evenly, place in a colloid mill for grinding, and set the rotation speed to 5000r / min, after grinding for 30 minutes, vacuum and degas, prepare the content material liquid for use;

[0048] Step 3. Take 40g of glycerin and add 100g of purifie...

Embodiment 2

[0051] The preparation method of the EGCG Ganoderma lucidum spore oil soft capsule of the present invention includes the following steps:

[0052] Step 1. Mix 15g of beeswax with 160g of Ganoderma lucidum spore oil, heat to 70°C to melt, stir at 200rpm / min for 15min to make it evenly mixed, place the mixture in a sonicator under 100Hz ultrasonic vibration for 30min, the concentration will be 100mL of 0.2g / mL EGCG solution was slowly injected into the mixture, and after the mixed solution changed from turbidity to clear, a nano-microemulsion solution embedded with EGCG was prepared;

[0053] Step 2: Add 8g selenium-enriched yeast (2.5g / L) and 20g lycopene oleoresin (containing 10% lycopene) to the microemulsion solution, stir and mix evenly, place in a colloid mill for grinding, and set the speed to 6000r / min, after grinding for 30 minutes, vacuum degassing, prepare the content material liquid for use;

[0054] Step 3. Take 40g of glycerin and add 100g of purified water and heat to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com