Photosensitive resin composition, yellow light slurry and preparation method thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of inability to reflect the high-resolution characteristics of yellow light materials, shedding, poor adaptability of inorganic metal powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 (preparation of photosensitive resin composition)

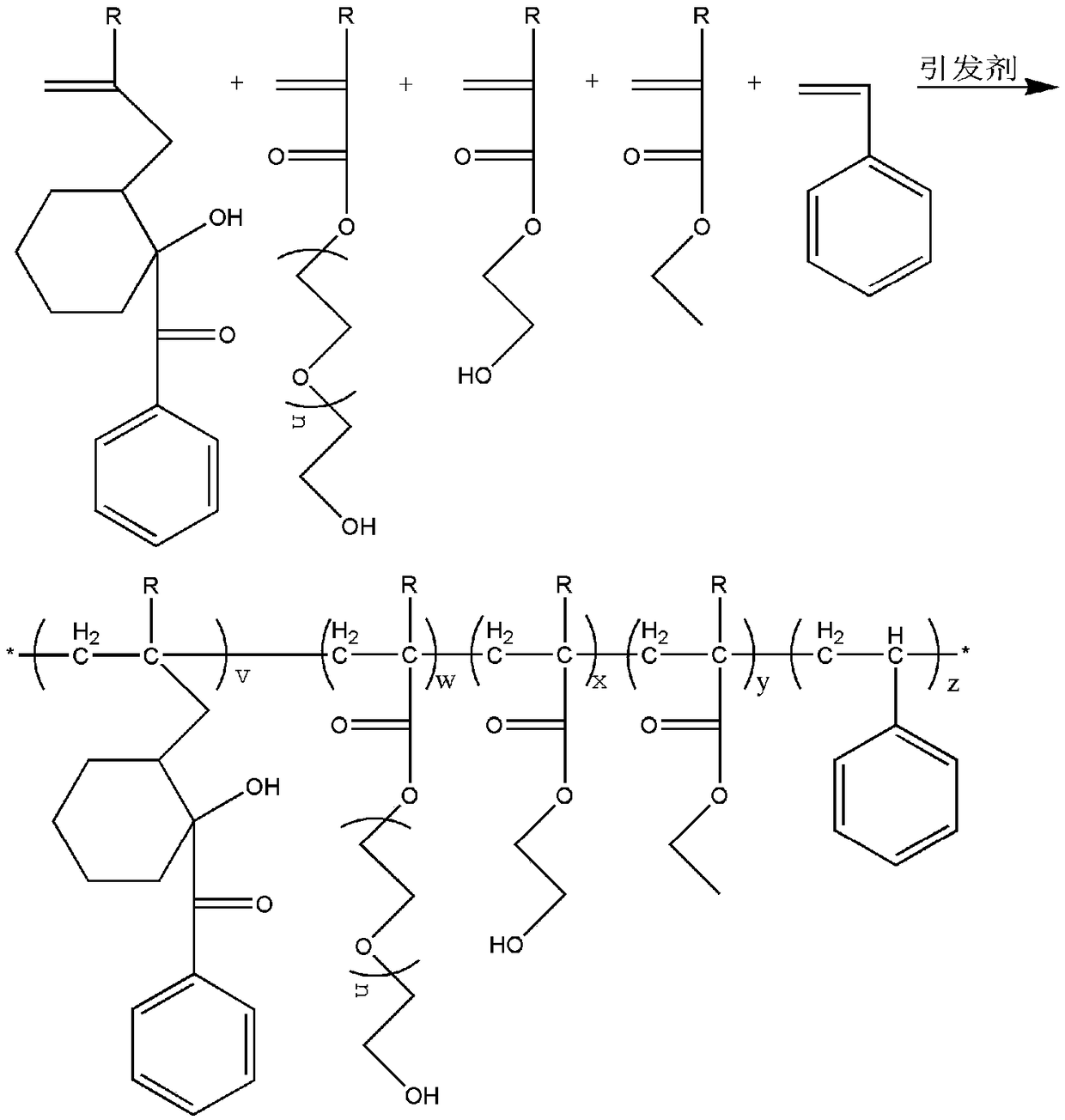

[0078] [1-Hydroxy-2-(2-allyl-1-yl)cyclohexyl](phenyl)methanone (2.5g), polyethylene glycol methacrylic acid (2.5g), hydroxyethyl methacrylate (7.5g), ethyl methacrylate (7.5g), styrene (2g), azobisisobutyronitrile (0.8g) were ultrasonically dissolved and mixed. Add propylene glycol methyl ether (70g) into a glass reactor with a reflux condenser, and stir under argon protection at 85°C. The aforementioned mixture is gradually added dropwise to the glass reactor through a dropping funnel, kept at 85°C, and stirred for 4h to react, see figure 1 , to obtain a self-initiated self-crosslinking photosensitive resin composition. The prepared photosensitive resin composition has a molecular weight of 18000-20000 and a glass transition temperature Tg=150-180°C.

[0079] figure 1 This is the general reaction formula for the formation of high molecular polymers in the preparation of the photosensitive resin composi...

Embodiment 2

[0093] 1) Organic carrier preparation

[0094] Get the photosensitive resin composition (60g) that embodiment 1 prepares, diethylene glycol monoethyl ether acetate (slurry solvent, 25g), hexanediol diacrylate (slurry solvent, 10.5g), gas phase SiO2 (thixotropic agent, 1g), modified polyether (leveling agent, 0.5g), trimethylsiloxane (defoamer, 1g), methyl phthalate (plasticizer, 1.5g), Acetic acid-[2-[2-[4-(2-chloroethyl)methylamino]phenyl]vinyl]-1,3,3-trimethyl-3H-indolium salt (0.5g) mixed, Stir until all the materials dissolve into a uniform liquid to obtain an organic vehicle.

[0095] 2) Preparation of yellow light silver paste

[0096] Weigh 65g of silver powder and 35g of the organic vehicle prepared in Example 2 and mix them. After fully stirring, grind and roll through a three-roll machine, and grind 8 times at a roll distance of 5-20um to obtain a uniformly dispersed yellowish silver paste.

[0097] According to the preparation method of the yellowish silver paste...

Embodiment 3

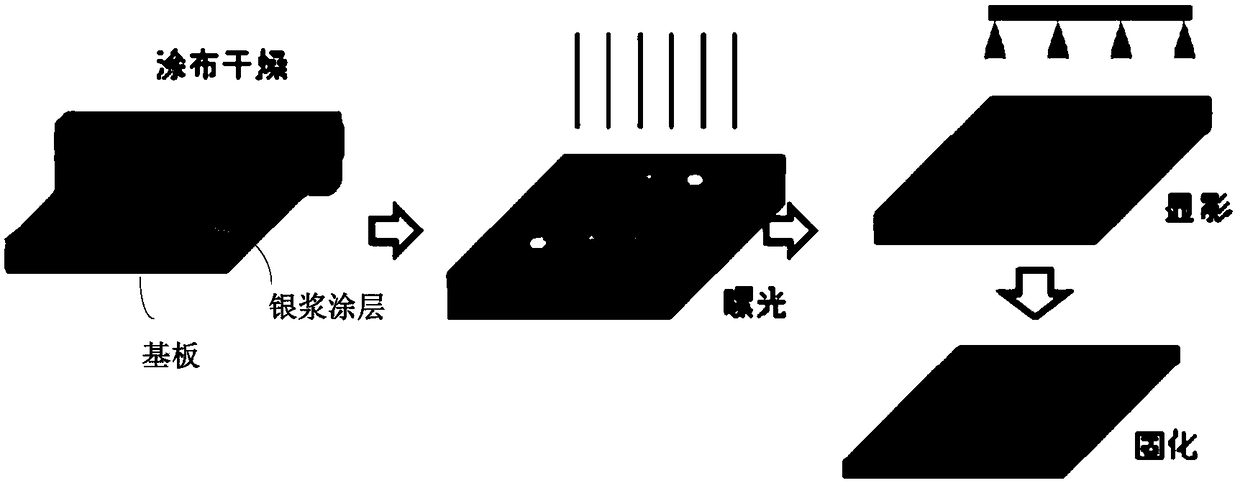

[0105] Embodiment 3 (substrate circuit preparation)

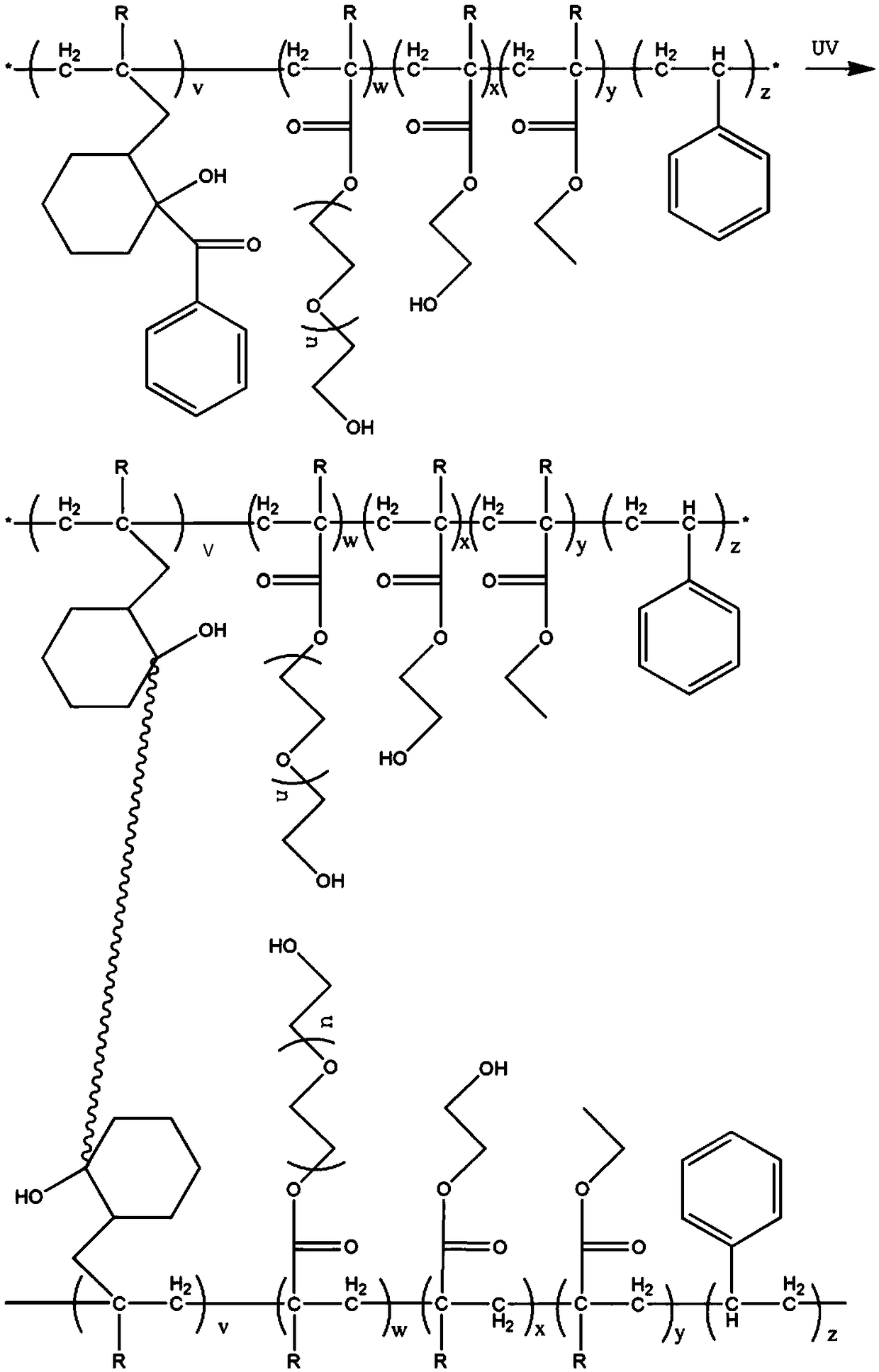

[0106] like image 3 In the substrate circuit preparation method shown, the yellow light silver paste prepared in Example 3 is coated on a polyethylene terephthalate (PET) substrate by 360-mesh stainless steel screen printing, and carried out at 90°C for 20 minutes Drying treatment, covering the film mask used for testing on the dried silver paste layer, using 200mj energy and 365nm wavelength ultraviolet light for exposure treatment, so that the photosensitive resin composition in the yellow light silver paste undergoes photoinduced exchange. Combined curing reaction, such as figure 2 As shown, remove the film mask, develop under 0.5% NaHCO3 aqueous solution and 0.2kg pressure, remove the exposed part in the silver paste layer, and obtain the circuit pattern of the substrate, including the test line and the test area of the grid method. Put the circuit pattern of the substrate into an oven and heat it at 130°C for 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com